Yes. The only mounting is on the face. The saddles and loop in the back is to hold it firmly in place vertically.

I’m now looking at mounts to isolate shock and vibration from the kart to the motor.

Yes. The only mounting is on the face. The saddles and loop in the back is to hold it firmly in place vertically.

I’m now looking at mounts to isolate shock and vibration from the kart to the motor.

Here is my preferred working layout if I end up using the Sony VTC5A 18650 cells. It is quite similar to others designs for the reasons that there are only so many places to put things with these larger packs (although the 18650 one is smaller than a 26650). Some dialog with others running electric karts with TAGs validated that I was pretty much spot on although I’ve upped the voltage some for a different controller. A 38S11P arrangement should provide enough juice for an 8 minute race (final) plus 2 warmup and 1 cool-down laps. The cells would be stacked 2 high with 2 sets of 9, 11 parallel cells plus another in the front.

I would anticipate this moving the front-to-back CG line rearward about 2 inches from when I ran with the 80cc Honda shifter engine. Side to side it will be fairly close to balancing out the new components, although by design the kart is always heavy to the left as that’s where the heavy carbon unit sits.

Waiting on results with the Lipo brick tests, although I am more conformable with li-ion and this pack will be no heavier - and a bit less expensive.

How much does engine etc vs batt weigh? Can batt be split up to optimize placement?

Yes of course. However that means added weight from more protective casing, mounting, and battery lead wire. So in general not worth it unless it is too unbalanced IMHO.

The engine was (without mount) just under 42 lbs including the carb and fuel pump. The fuel lines and tank - another pound or two. A gallon of fuel, another 6 pounds. Total around 50 lbs.

So far best estimate so far with the 18650 cells (below) is around 118 lbs for everything.

Kolme was able to do some short tests with the Lipo pack he built, and so far it looks very good. The cell choice for the pack and one other thing is holding me up at the moment from moving forward with the build…

After correspondence with the very helpful people at DHX Machines to get a wiring diagram for my motor, I found out it was originally sold to a motorcycle manufacturer (no they did not say which one) for testing. They asked me to remove the rear cover and send photos to confirm if it is an encoder or resolver feedback motor. I did and… well neither. It looks like the rear of the shaft was sheared or cut off, with the wires just cut and left inside the cap. Hardly the “new” condition it was sold as. It has been sent back to them for inspection and hopefully by next week I’ll know how I’ll proceed. Most likely the rotor will need to be replaced and I’ll finally be able to choose which controller to go with.

So my plans for this weekend is to get the frame cleaned up, and to weigh it “naked” with me sitting in it to better understand where I need to place components for decent weight balance.

that’s a rough break on that bum motor shaft. I’d be calling the seller and having some words. Hopefully you can get decent support from DHX - their website is scant on information.

June (crazy that it’s already June) update. DHX Machines - awesome company led by engineers with great customer (even 2nd hand) support. Yes their website needs work, hopefully that will get a re-do soon. The twitter feed really shows what’s going on.

The BAD…

I sent DHX the motor. The Ebay seller was a complete fraud, it was at best a good looking display model.

It had no resolver.

It has a damaged shaft.

It has a non-functioning stator.

There are no magnets on the shaft!

Etc…

I offered to pay them for their inspection time, but they would not take any money. So refund time it is (and an alert about the seller to Ebay).

The GOOD:

New models are coming soon. “we are working on the Peregrine series which combines the performance of the Hawk series with additional technology from PDC (product development contract) motors we developed over the past couple of years. It is designed to be more compact, lighter and DFM [designed for manufacturability] to be more affordable. Keep an eye out on Instagram or twitter for the release announcement later in the year.” - Sumari Mayor, COO

Since there really are no other compact, high-performance water-cooled motors I think I will just wait. Maybe I will be able to beta-test one…

P = I * E, Joule’s Laws of Heating, and adding “lightness”

Anyone who has had a basic electronics course knows that P = I * E, that is Power equals Current (I) in Amps times Volts (E). Via experience you may also know that to carry more current you need a larger wire so that it does not get too hot - which Joule’s Law of Heating addresses. Both of these are vital to understanding what components to choose when designing an electric vehicle, especially a “lightweight” electric sprint kart. Here are some things I have learned in the last 18 months or so, and why for now I am patiently waiting for a new appropriate (and lower cost) motor.

There are four main electrical components that have to work in balance to power an electric kart:

Today the Motor…

I start with the motor as it drives the requirements for the controller and battery (which then drives the BMS requirements). First you have to decide how much power you require to match whatever gas engine you are targeting. For me that was a TAG 125cc kart. An IAME x30 TAG engine is reported to develop (at the sprocket post clutch), 28 HP (20.9 kW). Using that, I now have a target for the motor output.

In choosing the motor certain obvious things are considered:

A few less obvious things that also need to be considered for motors are:

General types of motors to choose from:

Some of the specifications that will normally be on a motor:

Motor Type - DC, BLDC, Induction, SMPM, IPM, etc.

Nominal Speed - Usually the RPM where it is most efficient, usually where power and torque overlap

Max Speed - As fast as this motor should be spun

Continuous Torque - Torque that can be supplied continuously

Max or Peak Torque - Torque maximum that can be supplied for a brief period

Continuous Power - Power that can be supplied continuously

Max or Peak Power - Power maximum that can be supplied for a brief period

Nominal Voltage - Max voltage that it should normally be run at due to insulation or other criteria

Nominal Frequency - The motor power frequency (Hz) for which the motor will produce the rated (continuous) power at the rated (nominal) speed when getting the rated (nominal) voltage and drawing the rated current

Rated Current - Continuous current ratings

Max or Peak Current - Current max that can be supplied for a brief period

Number of Poles - Just that

Phase Inductance - Generally lower inductance is better (more efficient)

Phase Resistance - Generally lower resistance (lost energy due to heating up wire) is better

Max Efficiency - At the sweet spot, this motor can be this efficient at turning electrical energy into mechanical work

I’m choosing an SMPM motor (unless a suitable IPM or SRM motor shows up).

Next time, the controller…

Controller (AKA as the Inverter)

I will describe AC controllers / inverters here as that is what I have researched. An AC controller has both continuous and peak ratings for output currents, voltage ranges for DC (battery) supply, and a peak AC voltage range (minimum being near zero). The controller has to match the requirements of the motor for peak voltage, possibly current (same or less), and rotor position detection. If the motor is rated at 144v and 250 Amps, you want a controller that can deliver the full 144v at the end of the race at the current level required to match the target engine (last straight condition). If the controller (and/or the battery feeding it) cannot supply the full voltage, then the motor speed is reduced. Field weakening can make up for a lack of voltage somewhat, but only at a high cost of current drain from the battery.

AC motor controllers create 3-phase AC from the DC input by chopping up the DC into very short pulses exactly timed to correspond to the position of the motor’s rotor. Here’s a video that explains this concept quite well in the context of stationary Variable Frequency Drives, which are essentially simpler versions of a traction motor controller without the initial AC to DC conversion:

Voltage

Something very important to note here is that the voltage input IS NOT the same as the voltage output. You cannot put in 144v of DC and expect to get 144v of AC out, you need more DC voltage than AC to hit your target. The formula to compute what the battery needs to supply voltage wise is:

Motor voltage / SQRT(2) * 0.95

For the example 144v motor we would want a minimum voltage from the battery of:

144v / SQRT(2) * 0.95 = 214.4v

This eliminates a lot of the cheaper low-end controllers. Higher voltage parts cost more money, but give that back in higher efficiency (less battery costs, size, and weight).

Current

The current input from the battery to get the desired output is dependent on the motor efficiency and the controller efficiency. For our X30 we want 20.9 kW of output at the end of the straight. If our motor is 94% efficient and our selected controller is 95% efficient we get:

94% * 95% = 89.3% efficient combination. Since we want 20.9 kW output, we actually need to input (from the battery):

20.9 kW * (1 / 89.3% ) = 23.4 kW of power.

Since that power is dependent on the battery, high efficiency motors and controllers is highly desired as here 10.7% of that energy is wasted as un-wanted heat.

Controls and the CAN bus

The primary input is of course the accelerator pedal. For most controllers you have a choice between an analog variable resister based unit, or a CAN based unit. I don’t think either one is particularly better, but the CAN unit may be easier to capture data from for latter analysis.

Brake input is next. Depending on the State Of Charge (SOC) of the battery and temperature, you could use regeneration to put power back into the battery before the physical brakes take effect, or in combination. I say SOC and temperature because at the very start the battery will be full, and cannot accept more charge.

Modes: “Park”, Drive, Reverse. Yes you can have electrical reverse. Handy for off-track excursions.

Emergency Stop. Cuts power for safety, usually with a large switch. I am considering using a dead-man switch lead like those with watercraft in case I am ejected from the kart, rendering it safe by default.

Cooling

Some of the choices have air cooling, some have optional cooling plates for water, and some are built-in with water cooling. For short races, I may be able to get away with just air cooling since I will not be running any of the choices at more than 100A.

Programming

All controllers need to be programmed to work with the specific motor you choose and the BMS so it knows the state of the battery. Through whichever interface is provided, you can “tune” the motor to limit how much current and voltage you wish to provide to make the battery last. Many have at least two modes that could be used for say, normal lapping and (extra current) push to pass - much like Formula E or Indycar.

Output

Since all controllers of this caliber now use the CAN bus, any information on that can be displayed by either dedicated displays or old phones / tablets. Readability is important, but honestly having just the SOC and any temperature warnings are all anyone can hope to monitor while racing. Recording the CAN bus messages for later analysis is very nice to have to see how the entire system is working together, or where faults are occurring.

Choices…

There are several mid-voltage controllers to choose from. Here on the ones on my list:

DC Voltage Range, Continuous current, Make and model, URL

50-420v, 300A, Cascadia Motion RM100DX - https://www.cascadiamotion.com/rm-family-medium-volume.html

50-400v, 300A, Cascadia Reinhart PM100DX - https://www.cascadiamotion.com/pm-family-low-volume.html

128-400v, 200A, Sevcon gen5s9 - http://www.sevcon.com/products/high-voltage-controllers/gen5-s9/

50-400v, 210A, YASA Si400 - https://www.yasa.com/controllers/

?-400v, 300A, Axiom 100+kW (open source design not yet in regular production) - https://hackaday.io/project/164932-axiom-100kw-motor-controller

200-425v, 400A, Scott Drive 100 - http://scottdrive.co.nz/Scottdrive100.html

I am undecided on which one to use yet. The controller, BMS, and Charger (when charging) need to all be able to communicate to keep everything safe and in check at all times so interoperability is key.

Next time, the Battery…

Battery

Manufacturer’s data

You’ve probably heard that there are lies, damned lies, and statistics. The cells that make up a battery definitely fall into the worst of that, at least in regards to how we use them with racing. Whatever it says on the package is for a very slow drain rate over two hours, not N minutes. That rate is identified as the C rating where 0.5C = 2 hours, 1C = 1 hour. Since a ten minute lap is usually complete in 8 minutes, that’s 60 minutes / 8 minutes for a minimum C rating of 7.5. Depending on the cell chemistry you may have few choices with this level of drain.

A battery is composed of one or more cells. Each cell can only provide a given amount of current at a certain voltage, varying over use. Some packaging groups a number of cells into one container and then the data is provided for that “brick” or prismatic “cell”. Common specifications are:

Total mA - Which assumes that this would have been charged to 100% and ran down to the minimum cuttoff voltage, as new

Peak or Max v - The charge voltage that it should be able to maintain for a short period, when fully charged with no load

Nominal v - The voltage more likely you will see when you apply some amount of load

Cuttoff v - The voltage the cell either internally switches off at, or your controller better switch off at to avoid damage

Peak or Max C discharge rate - As discussed above. For karts with an 8 minute final you would need 7.5 C

Peak or Max discharge rate in mA - How many mA you can draw safely (on paper)

Peak or Max C charge rate - How fast you could (but probably should not) charge the cell(s)

Recommended C charge rate - How fast you should charge the cells for long life (and best safety)

This information provides a starting point, but you need to find actual test data at or near the rate you plan to discharge the cells at to understand how they function in real world use. This will give you the real start and end voltage sag so you determine how many serial cells you will require to maintain the minimum voltage input to the controller. Based on the actual amperage delivery you can also determine how many cells need to be in parallel to carry the load.

Computing how many of what is needed

This is the difficult part. Since batteries are a moving target with regards to temperature, state of charge (SOC), and condition. Since it does no good to almost finish a race, I have made these assumptions in calculations based on worst-case. This should always provide some margin in case there are extra pre-start laps, yellow flag laps, etc.

Target. What is it we are trying to match in overall speed? For this example I will use a 125cc x30 TAG engine as the example. Of course these ratings are peak and not RMS averages over a lap - this is where a lot of the margin will come from:

IAME TAG x30

28 HP / 20.9 kW

14.4 Ftlbs / 19.5 Nm

Again these are peak values, not linear, and that area under the curve matters. Here is an overlay of the x30 data vs what an electric motor adjusted to match the peak HP of the X30 can do (although we can adjust the peaks within motor limits):

This dyno plot shows the instant torque you expect from an electric motor (at WOT), along with the linear HP line from 0 to the point where the controller (in this case) starts to trade torque for rpm (“HP”). In comparison the 2-stroke has to spin quickly in a narrow range to make the HP. So if we just shoot for the peak HP assuming the 2-stroke will be somewhat close we are very wrong. What we are matching is the ultimate speed at the end of the straight (HP) with the centrifugal clutch fully locked up. So we reduce this electric motor output to better equal the two, but here I am using the peak HP number just to get an idea of how much battery capacity is needed.

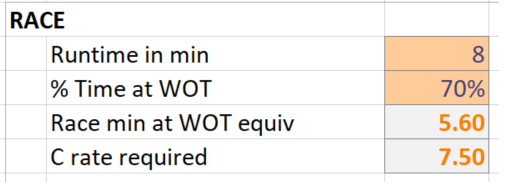

RACE

Here are the values I am using for this calculation for the race itself. Percentage of time at WOT is based on watching throttle traces from TAG karts and averaging the value. This gives an equivalent WOT time to base power calculations on. The C rate is based on the number of minutes as discussed before.

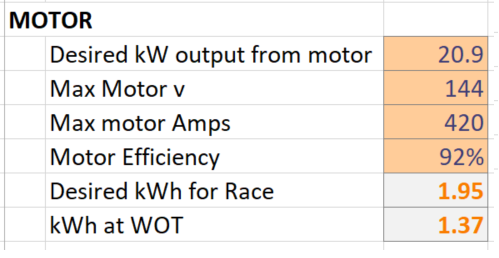

MOTOR

Here I set the desired kW output from motor (how much “HP”), what my selected motor’s max voltage is, the max amps, roughly how efficient it is at converting electrical energy into mechanical energy. From that I calculate how many kilowatt hours of power I need and how much of that will be at WOT equivalent.

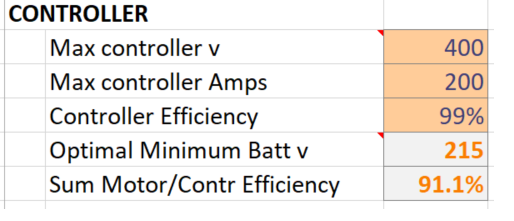

CONTROLLER

Here I input that specification values for the selected controller. From the max voltage of the motor and controller I can calculate what I need (not necessary will get) to avoid field weakening. I also multiply the efficiency of the motor times the efficiency of the controller to get my output efficiency. This is used to increase the number of kWh that the battery needs to supply (above the losses to heat).

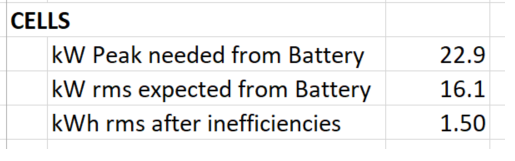

CELLS

Here the kW Peak needed from Battery shows that peak number with the heat / mechanical losses added in. The battery has to be able to meet this for short periods. kW rms expected from Battery is how much capacity we need to do the work over the race. kWh rms after inefficiencies

is that rms number adjusted for time to get kilowatt hours.

So now we finally get down to inputting battery data to use some of the above information. There are about 4 general types of “cells” you have to choose from when making a custom battery:

These are your 18650, 21700, 26650, etc. The metallic cylinder measure for an 18650 is 18mm in diameter and 65mm the length. I guess 1865 didn’t sound as good. This type give you the most choices of battery formulas to choose from. Of these there are really only one I know of that really makes any sense for our high drain demands - the ex Sony, Murata VTC5A. A nice 2600ma 11.5 C cell. However, they are a pain to package in a manner that is strong enough for kart use, has sufficient buss bar capacity to carry the load, and enough cooling to tolerate high drain races.

These are make optimal use of space by using the layered approach in a single container. This is the type used in your cell phone to save space, but can also be made very large to suit specific shapes an OEM may want to fill in a vehicle.

Pouch cells eliminate the metal enclosure of the prismatic cell to reduce weight so the cell needs external support and allowance to expand in the battery compartment. Generally these are Li-Po chemistry and the ones we are interested in are for the RC specialized market where high drain rates are required. They are normally packaged in 2S-6S configurations (bricks), which greatly reduces the number of “cell” connections that will need to be made over individual cylindrical cell packs.

Here is a sample of some cells that I researched as possible candidates for a battery pack:

BATTERY PACK

Here’s where all that data comes together to help you choose what to buy and assemble for the battery pack. 18650’s generally have a weight advantage - until you also add in the heavy copper buss bars and all the holders that will be needed to make a pack (and keep them there under shock and vibrations. Lipo bricks are much simpler to assemble, put up with shock and vibration much better, and make for a very compact energy dense battery (a good thing on a small kart).

I’m waiting to pull the trigger on all of the above until I have a new motor in hand. That drives most everything else so you don’t want to get stuck with sub-optimal items by jumping the gun.

Till next time…

BTW - I plan to make this spreadsheet available so you can just plug in values to help in your choices, I just have to clean it up a bit.

Wow, amazing thread! From a fellow engineer, really appreciate the thoroughness. Now I got the bug to build an ekart. Can’t wait for more! Nice job.

Here is what I think is a reasonably correct and complete motor / controller / battery spreadsheet to help understand how various choices of components effect the overall package.

If you find any errors or obvious omissions, please let me know so I can correct this.

https://drive.google.com/file/d/1_xFfOye3ZaG-EF-dPyiVmUtbUWNl-qV1/view?usp=sharing

Version 1.2. I had some time to add a few motors to choose from, so I hope that helps. BTW, any of the tabs for input can be edited, just make sure to insert between the first and last entries so that it stays in the range.

https://drive.google.com/file/d/1M4YgIdHQ2eigD-IR69hZyRLarfHbATD-/view?usp=sharing

Version 1.3

Added:

WAG on Engine to Motor performance balance

Motor current calculations

Top speed calculation

More motor choices

More controller choices

https://drive.google.com/file/d/12zzOV-7sqUpvYe8b3BMkESu22b226cNz/view?usp=sharing

Let me know what else would be helpful. This is for PMSM motors, not brushed DC or BLDC.

Version 1.4

Added / Changed:

Split-up Setup from battery choices

More battery choices

More motor choices

More controller choices

Fixed:

Ah ratings

I decided to bid on an insurance Zero motorcycle, hopefully I’ll get it for a reasonable sum to get this project back on track, at least after a long road trip to pick it up.

To start with and keep things simple, I plan to basically transplant everything from the bike onto the kart, minus the charging module (and all the bike only stuff of course). The battery is overly large at 7.2 kW, but the pouch cells it uses are actually a pretty good fit for racing use with a fairly high C rate. The motor is air cooled, but this is a newer IPM model so it should run cooler than the older SMPM motors - at least when I’m not tempted to push it to the 52kW limit

I’m chatting with some other Zero people to see how to best charge the pack with a 3.3kW off-board charger. Hopefully I can get one that can talk to the battery BMS so the charge rates are ramped for better battery life (the BMS either way will shut off the contactor when it is fully charged).

Can’t wait to get started!

Why is it called an “insurance zero” motorcycle? Not street legal?

it’s a Zero-brand motorcycle that has been wrecked, stolen, or otherwise totaled by insurance. Insurance companies often sells their salvage vehicles at auctions.