Nope. Tyler is local to me, so it was an IKF event. (USA0

I’ve been told (I’m not sure if its just a rumor) that when Intrepid used the 09 chassis to dominate supernats they were coated with a ferrous paint. After I found out about this, I put a strong welding magnet on my kart and my dad’s 2012. The magnet fell right off of every tube on mine and required effort to remove from the other.

From what I recall they used lots of metal flake in the paint as Tyler said. So it barely passed the “magnet test”. The problem was that the paint then just flaked off constantly, and then was no longer magnetic.

Why was the metal being non-magnetic a big deal? Was it a softer material or something else about it?

CIK-FIA regulations dictate that the chassis material must be made of magnetic metal, in the hopes that super expensive exotic materials will be limited.

Intrepid tried to pull a fast one on everyone by using some metal alloy for their tubes that was not ferrous.

and i remember that with Kozlinsky was super fast in KZ…

What does a different alloy get you that a smaller tubing diameter doesn’t? I’m assuming that alloy has a different spring rate?

Different flex rate or “springy-ness” I would assume. A lot of the difference is in how they heat-treat the tubing as well.

I’ve heard rumors that OTK has one place that does all their heat treating and no other manufacturers are allowed to use the same vendor, that there’s a contract in place or something.

There’s definitely a difference in the feeling of the material between OTK and other karts.

I’ve got the point with karting forums where I am copying and pasting from previous discussions lol, but…

There is more going on than I think is being discussed here. And there may be more going on then I’m about to discuss. Noting that this is all my observation, driving and engineering ‘knowledge’.

First split the corner in to 5 segments, braking, turn in, apex, turn out, exit.

For this discussion we care only about turn in, apex and turn out.

So, at turn in you are almost entirely dependent on the geometry of the steering, the inside front wheel pushing into the ground, the outside front wheel lifting off the ground, geometrical change along with change of direction caused by tyres turning. The chassis tilts, unloads the inside rear wheel allowing the turn to begin. You can see this happen with a kart on a flat piece of ground, turn the wheel and stand on the outside front corner, the inside rear will lift.

Once the turn has begun you remove some of the lock, lifting the inside front and lowering the outside front wheel. At this point chassis flexure becomes the dominating handling characteristic. The load provided by the weight transfer against the tyre grip and turn radius flex the chassis to maintain the rear wheel lift. How long it stays up and at what rate it falls back down again are defined by the grip, speed, radius of the turn, steering lock and chassis (and auxiliaries) stiffness. The point you are trying to achieve is keep the wheel up in the air as long as you are turning, if it drops you will understeer, if it is inconsistent (usually caused by a drivers weak arms) then it will hop and break a rib.

The really interesting part is the turn out, as you put the power on and you remove lock from the steering, do you want the inside rear wheel on the ground or not? I suspect not until the steering is straight. I suspect that most tyre compounds have enough grip in them that you can transfer all the engines torque through one tire, and so axle tuning (or release) is about getting the rear inside wheel to stay in the air even if it is ever so slight, until your steering wheel is straight. If it drops too suddenly you have double the grip with the same amount power and one wheel needing to slide to maintain the turn (bog) or it stays up too long and you have too much turn speed and half the grip and it slides which leaves you with slide and bog.

Did that make sense?

So smaller chassis tubing would make the chassis softer, but its heat treatment or alloy choice that changes the rate of chassis flex which is critically important for chassis handling due to the reasons above.

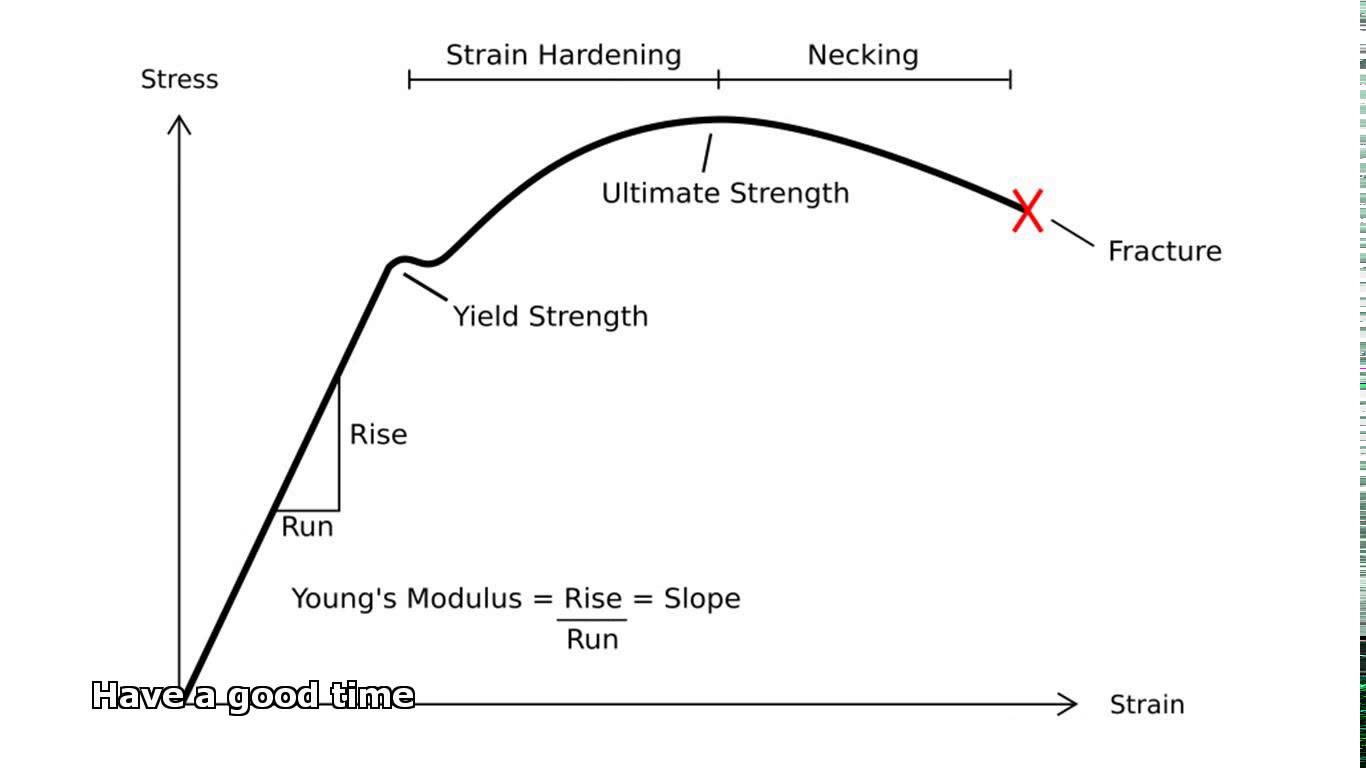

If I refer to the image below, I think chassis are designed to operate in the strain hardening region, which is why they only last a finite time. The heat treatment and alloy choice effects the shape of this curve.

Beautiful post.

That graph interests me. Why are we engineering the chassis to work within the strain hardening space, where we have exceeded the elastic range?

If anyone isn’t familiar with materials testing (Why would you? It’s kind of a pain tbh), the elastic range is the space in the stress strain curve where the metal is able to return to it’s original shape and retain the characteristics it had before being subjected to the force. It’s shown as the linear portion that starts the graph. Once we pass the yield strength point, in many situations, the metal is considered useless, but apparently this is ideal in karting.

As I think about it, a chassis likely reaches the upper part of the strain hardening curve within the first few weekends, hence why some teams prefer replacing chassis every 3 weekends. As the metal becomes harder, the strain is less, so it spends more time at the right half/two thirds/whatever fraction of the hardening portion of the curve.

The flexed out point we’ve discussed before probably happens close to or past the ultimate strength section of the graph.

Circling back to my original question, there probably are chassis that work in the elastic range, but they may be so stiff to stay in that range that they do not work great in certain or most conditions. The trick is probably to have an elastic range that allows a lot of flex, but I assume that’s hard to find if they haven’t done it yet.

/enginerding rant over

Excellent post.

This is all me theorising, so I could be wrong. I would suspect like you have said that some chassis stay in the elastic region or some chassis in some classes spend time in the elastic region.

The reason i’ve come to theory that they are in the strain hardening is reason;

-

The chassis go “off” so quickly.

-

All the chassis i’ve worked on in the last 5 years seem to be out a mm or two at the end of every day (probably at the end of every practice but we don’t have time to check). Conclusion is its gone past the yield point and probably does at every corner on the track.

That second point would go to the necking porion of the graph, which I think gives pretty good evidence on your theory there.

I wonder how much they’ve looked into this materials stuff (probably a lot)

No mad croc are different…the chassis is awesome…

Yes, but they are made by the same people, (EMME) and designed by the same guy (Armando Fillini).

The factory chassis are generally similar to what the “public” can buy. In my experience factory karts are not powder coated just spray painted, (sodi’s superNats chassis last year, factory FA kart I tested) and factories like aluminos and GP kart will leave bare metal. Not sure what changes they made to the design or metal but the karts are “softer” without powder coat helping with the flexing and rebound of the chassis.

As for how much faster they are is debatable. I do know that both factory sodi drivers at snats last year had two chassis to choose from. One special chassis and one regular chassis. Abbasse chose one and Lammers chose the other and they were seperated by less than a tenth pretty much the whole weekend.

Made it halfway through my junior year in mechanical engineering before taking some time off, then returning to change to architecture. Anyhow, I would think that most of the chassis spends its’ life in the elastic region, otherwise your settings (caster / camber / toe ) would change from beginning to end of the race session, as well as from race to race. It would be interesting to throw a frame on a surface plate after every race and check…(some do.) I suspect that it’s only a particular portion of the chassis, likely in the waist, that work hardens. And some chassis may never work harden (4130 chassis, I’d guess.) Interesting discussion. I’d like to run a full regimen of FEA on a chassis as well as some strain gauges. I think that there’s a wide range of possibilities in chassis development that have never been explored, most manufactureres instead preferring an iterative derivation from the basic configuration we’ve seen for the past 40 years…

Generally speaking an OTK is up a couple of mm after every run on one of the front corners. Sometime we also see waist twist too. @tjkoyen can probably talk about what he has seen.

They should be all 4130, as they claim to be chromoly.

@Connor_Wagner, I actually had a fruitful conversation with an OTK distributor late last year who believed the OTK chassis brands where different because of the paint spec and curing process required for the different colors. And on unpainted chassis, I turned up to the european champs in 2001 and was given an unpainted topkart that was exactly the same shape as road rebel. Wrong material but the shape was correct.

It’s funny. I heard that Roberto Robazzi (Mr Tonykart/OTK) owns the tube stockholders who supply most of the kart industry!

No idea how true it is. Given his reputation for attention to detail, I wouldn’t be suprised.

Hi guys,

Interesting topic! I’m an automotive engineer and i’ve spend a half year researching chassis durability and ways of improving it. Some guys make very good points here. Chassis are designed to work within the steels elastic range. Passing the Yield strength is the main problem when it comes to chassis durability. It will bend in the waist area changing the caster/camber/kpi and so on. Like mentioned before 4130 or 25CrMo4 chromoly steel is used by 90 % of the manufacturers, not heat treated. Hardening (the usual goal of heat treating) will make your chassis exteremely brittle and stiff ( think of a drill bit ). As for paint powdercoat or bare metal, it makes no difference to what so ever…

My question to you is what is the feeling you get from a worn out chassis? Most drivers use words like “it goes soft”. But a worn out chassis has the same stiffness as a brand new one (i tested this). So what makes it feel soft?