Really wish more brands offered a third bearing-less design like Arrow.

If I recall correctly all homologated karts don’t have a third bearing-less designs because it’s obligatory to have them.

Found out recently because the boss of a team wanted the senior drivers of the local sodi team be DQ’d after seeing they didnt have the third bearing. This happened because some years ago a Master driver was DQ’d because he didnt have the third bearing in his kart.

Any new insight on this topic?

If axle is indeed acting like a damper, then it’s basically controlling how fast the load transfers to the outside rear tire? Then it is similar to the compression valving on a damper?

A stiffer axle would transfer load faster than a softer axle? (to the outside rear)

And what is the axle dampening? the chassis flex?

I think another important question to test this theory is, why does OTK rear axle affect handling in opposite manner to other chassis makes?

The damping is insignificant. The stiffness is more analogous to changing springs on a car

The reason different karts respond differently is because changing the axle stiffness does two opposing things - stronger load transfer AND stiffer chassis. A stiffer chassis will understeer, but more lateral load transfer will tend towards oversteer. So which actually happens and to how much depends on the total kart

The elephant in the room is, how are steel axles with the same dimensions (length, diameter, wall thickness) different stiffnesses?

Given that all steel alloys have more or less the same modulus (considered equivalent in engineering calcs) due to the iron bonds being the predominant factor in elastic behavior, and that the stiffness formula is (elastic modulus * second moment of area) / (length), it follows that any iron alloy axle of the same dimensions will have the same stiffness. It is also worth noting that the karting lingo of “hard and soft” for describing stiffness is wrong. Hardness is largely, if not totally independent of modulus (stiffness). They are different properties that can correlate, but don’t always.

That said, I can feel a difference in “hard” and “soft” axles of the same dimensions.

What is going on?

Alloying and temper can change the modulus about +/- 5%. For general use, this is within the noise of whatever other errors are stacking up. My guess is this is “significant” in terms of handling for a kart though. Most of the axles I’ve seen firsthand though do change wall thickness, but this is far from a large sample size.

I’ve also often wondered if some of these axles are turning down the wall on the inside at different points, ie not a constant cross-section. Just a wild guess

I’m going to interject something here, just because I’m genuinely curious how it relates. Let me preface this by saying I’m not an engineer, so my understanding of vehicle dynamics is limited to a few book I’ve read over the years that attempt to explain it without getting too deep in the physics.

One idea that stands out to me from that reading though, is that it’s typically described that the total lateral / longitudinal weight transfer for a given acceleration is affected by only three things.

- CG height

- Roll Center Height

- Track Width / Length

Every other adjustment only affects how fast the load transfer but in no way changes how much total load is transferred.

My questions are:

- Is what’s typed above accurate?

- If so, how does it relate to a kart where the roll-center (assuming there is one that can be mathematically derived) is static as opposed to dynamic, and more specifically if the above is accurate, how does it interplay with the whole axle stiffness thing?

Thanks

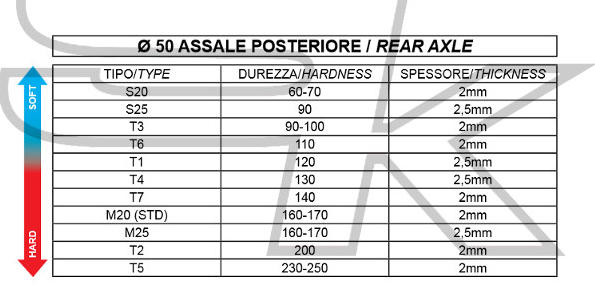

Food for thought, here’s the CRG axle chart:

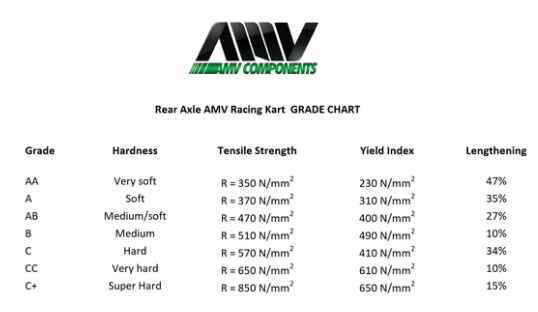

Just for comparison sake, @Paul_Montopoli posted this elsewhere but here is the AMV axle chart.

@Muskabeatz do we know what the unit of measurement is for the “hardness” in the CRG chart?

Where I have a very strong objection to this is here:

If the axle is yield every turn, it will be growing longer and the wall will be growing thinner every rotation and every turn. That chart implies the loads are higher than 650MPa, so a 230MPa axle would be growing very, very significantly. There is also no control to make sure it is growing in a straight line, so that AA axle would be an absolute wet noodle.

Assuming the AA axle is not a wet noodle, this means the peak load is less than 230MPa. If peak load is less than 230MPa, increasing the yield will do absolutely nothing, and a C+ would perform the same. We know this is also not the case, so I argue that the yield strength is a Red Herring and other factors are actually at play (like wall thickness and other variables)

No, because the kart has four very stiff points of contact. Changing the stiffness will change the dynamic cross-weighting. Think of a four-legged chair but you replace one leg with foam. The load on that leg will now be much lower (as long as the CG is such that the chair doesn’t tip).

Weight of the hammer required in order to straighten the mf’er…T5 is mislabeled and should be ∞ hammer weight.

In all seriousness I have no idea. AMV’s chart is cool, but I have no idea what those mean.

For the CRG axles, it seems like there may be something with axle wall thickness, and matching to the chassis. For example, with some of the recent chassis I’ve driven (Factory Kart, TB) I’ve preferred the 2.0mm CRG axles (T6, M20, T2). However, with the current GP15 chassis we’ve seen good results on the 2.5mm axles (S25, T4, M25 in particular). The chassis is made at CRG and uses the same axles as CRG. I have yet to test the 2.5mm stuff myself, but the chassis feels different enough from others I’ve driven that I could see a case being made for it working well with different axles.

Anecdotally I have been told that from manufacturers that they have tested down to 1mm wall thickness axles recently. Not legal for competition anywhere really, but just to study the effects.

And no, the 1mm wall thickness did not deform or break from normal usage and is “still testing”.

No idea what any of the numbers mean or how to draw conclusions from that, as noted many times before, I’m not an engineer and some engineers tell me that I’m being lied to by other engineers, so I have no idea. ![]()

I believe this, and it supports my statement that the axles are not yielding. If you are not reaching the yield point, increasing the yield point does absolutely nothing. That’s a statement of absolute fact.

Typical hardness testing is also just a measure of yield point. Hardness testing looks at the size of permanent imprint and is in no way a measure of elasticity. So hardness and yield both point to how much load is required for permanent deformation. They do not inform you to how stiff a material is prior to permanent deformation.

At best, axle tuning is just so hyper-sensitive that the small (+/- 5%) change in E as a function of alloy and temper is what matters. I cannot refute that statement, but seems to me like there is a lot of smoke-and-mirrors going on in order to protect IP

I think you’re onto something here. Perhaps yield strength is only relevant for acute incidents like monster curb or if you go Bigfoot on somebody (example below). Some of the really soft axles out there in the world are notorious for bending easily in such incidents.

Also, I was joking about it earlier, but certain “hard” axles are noticeably more difficult to straighten, and essentially impossible to do so with a hammer.

Again, I know nothing except my experience but I have bent (super soft) axles from normal usage, not impacts or hitting anything or crashing. Not refuting anything just making a note.

In normal use it would be wild to assume a standard axle would be close to yield, obviously that doesn’t make sense. But in cases of extreme grip I think it’s possible to get a “soft” axle to the yield point.

Sure, but in normal use changing the axle still changes the handling. Ipso facto, it is not yield that changes handling. Yield/hardness may be the result of other changes like the alloy or geometry, but they are not what drive handling changes.

Agreed.

So question just for my own learning:

Looking at the AMV chart for example, the B axle has a yield of 490 and a tensile strength of 510. If the yield is close to the max tensile strength, does that mean the axle is more brittle? Like it has less flex/deformation before it fails/breaks?

Strictly speaking, yes. But, if the Young’s Modulus does not change (and it typically does not for steels of similar makeup), then the amount of deformation before it yields is unrelated to the “tensile strength” as AMV has it labeled. They really should call it the Ultimate Tensile Strength (UTS) since just “tensile strength” is ambiguous.

Two steels with the same E will feel the same in the elastic region until one of the two is pushed hard enough to permanently deform.

“Toughness” is the measure of how much work it takes to fully break something. When the UTS and YTS are close, this is usually low. Although you could have a material with a very high YTS and close UTS still take a lot of work to break. So it is brittle in the sense that they are close, but it could still take a ton of energy to break.

We are for sure operating in the elastic range only. Once yielding happens, the axle is bent. If it is true that there is some signficant variability in the modulus of iron alloys (+/-5% as stated earlier), then that could easily explain how steel axles of the same geometry behave differently.