I just love this guy. Anybody know what happened to him? Anybody know his surname? I’d like to track him down.

Here you go Ademir. You nearly got it all.

(Your written English is exceptionally good BTW)

Enjoy!

Rate of lift is a term invented by matt Hayes ______ and myself to help the driver And pit crew ______ to discuss the behavior of the go kart. I found it really helpful term to use and I encourage you to use too if you find it works for you.

Basically, rate of lift means the fast you lift the wheel, the fast you drop the wheel.

So, here we come discussing rate of lift is helpful in karting.

Basically because there are conditions where a fast rate of lift is an advantage and there are conditions where slow rate of lift is an advantage. Judging the conditions you are in and choosing the rate of lift suit those conditions is where the strength of this analysis comes from.

When the track is slippery you need to get the inside rear wheel off the ground as quickly as possible in order to allow the nose of the kart to turn in to the apex. Not only that. But in the exit of the corner having additional rubber on the track in both front and rear wheel can actually be an advantage because the track is slippery. In this conditions, a fast rate to lift is the go. Lift the wheel quickly, then put the back down on the track and go.

*When the track is grippy the front tires can generate a lateral G forces required to start turning the kart before the rear wheel start to lift. So, this mechanical jacking effect becomes less and less important. Not only that, but as you come round to exit of the corner you need to keep inside rear wheel unloaded for as long as you physically can. In this conditions, a slow rate of lift is what you are after. Bring the wheel up slowly, not necessarily very high, let it hover__ there for as long as possible, and when it does come back then to make the track do so very slowly and gently. *

Rate of lift is obviously not something you can measure with the steel ruler. It is a relative term we use to compare the kart with those of other competitors around you.

So, how do you know What your rate of lift is like? if kart comes on really quickly and goes off really quickly you’ve got a fast rate of lift. If kart takes forever to come on you’ve got a slow rate of lift.

You can also look the type of the corners and whether you go strong or weak compared to the competition. If you are really strong in the tight corners and hops on the sweepers, you’ve got a fast rate of lift. If there are hops in the tight stuff but the karts a weapon _______ in sweepers, you’ve get a very slow rate of lift.

Hopefully I’ve convinced you the tuning your rate of lift is a powerful way of get the setup of your kart right. So, how we change the rate of lift? Well, by changing just about anything.

Almost all the changes you make to a kart will affect the rate of lift. You often hear me refer to the rate of lift when we are discussing a particular setup change in the rest of this tech videos.

I’ll give you a couple of examples to think about now though. Anything that increases your mechanical jacking effects so changes like more caster, more _Scrub radius _______ , more Ackerman, or bolt on front hubs. They will all increase your rate of lift. The more mechanical jacking you put into the kart the faster your rate of lift will become.

Changes at the rear of the kart that causes the outside rear tire byte harder also increase the rate of lift. Examples here might be running a narrower hear track or raising the seat height. Both of these changes will increase the rate of lift in the kart.

*I often say, karters get frustrated when they can’t get their kart setup right. It particularly happens when you are in conditions they aren’t familiar with or the track where they aren´t familiar with. When you are outside of your comfort zone, using rate of lift analysis tool can be a really helpful way of getting the kart setup right. *

Watch your kart out on the track, compare where on the track or when in the session it is fast or slow compared to the other guys around you.

See what that says about your rate of lift. Is it your rate of lift too fast or too slow? Having made that decision, have a look at the kart setup and see what changes can be made to adjust that rate of lift to better suit the track.

I think you´ll find this to being extremely effective way of thinking about kart setup. "

Credits to KRACER

https://colfink.com/?fbclid=IwAR3j67hqBvO2Kgb00TTir5WxjVYXnqgmuPHjhP_eKTWGdUVwh5T-RO6bjP0#colfink

His time in Karting is well and truly over unfortunately after selling up KRacer to DPE engineering here in Australia and pursuing other interests.

What a pity. Such a talented presenter. His videos were really easy to understand. K-racer lives on!

Thank you very much @Motormouse for filling the gaps ![]()

I think Col Fink realized the talent he has to pass the message, so he is flying higher now taking advantage of it. Good for him. I hope he do not forget the amazing sport we have.

Appreciate that Paul. Do you know him?

What part of oz you in? I’m on the Gold Coast. Come to the Race of Stars during the GC600 if you’re ever up here in August. Racing like you’ve never seen.

Thanks mate.

Happy to help Ademir. I got a lot out of this exercise actually. You’re transcription gives me something to read which is how I’d rather learn.

OK, I’ve thought about this for years, so I’m putting this out there.

I believe that there is much confusion created by the using the term stiffer and softer together and as antonyms (the opposite of each other). Stiffer describes how much deflection there is for a given force and softer describes the material’s resistance to local deformation. One can make a judgement on whether an axle is softer or harder by the size of the /dimple in the axle created by the axle set screw.

In general most 50 mm axles are 2 mm thick and therefore the dimensional characteristics between the hard and soft axles are the same and since the modulus of elasticity(~Young’s Modulus) are the same for all steel, regardless of carbon compound or hardness then what makes karts behave differently with different types of axles?

The way to rationalize kart behavior wrt axles and maybe even chassis to some extent, is thinking in terms of static stiffness and dynamic stiffness. All axles have the same static stiffness because they all have the same dimensions and because they are steel, they have the same modulus of elasticity. Push down on the end of an axle and they all deflect the same amount. Nevertheless, it is generally recognized that different axles (with the same cross-sectional dimensions) affect kart behavior and the hardness/softness of the axle seems to be most obvious characteristic that affects handling.

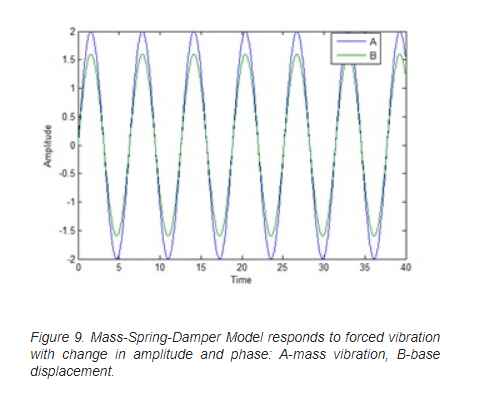

Hardness and the alloy mix according to multiple research papers affect the damping of steel. Damping is what determines dynamic stiffness. An analogy are the dampers or “shock absorbers” in a car. A car with variable damping can be set to high dynamic stiffness or low dynamic stiffness by increasing the damping yet the vehicle will still deflect the same amount statically. See the figure below. A represents low dynamic damping and B represents high dynamic damping, note how the deflections changes from A damping to B damping.

The part I have trouble with is the rotating frequency of the axle high enough to be affected by internal damping of the material.

After all this, it’s pretty simple use a soft axle for low grip conditions and a hard axle for high grip conditions, at least for most karts and under most conditions. Screw trying to rationalize through an engineering perspective.

Guys, sorry to go back to this again, but I still have some questions that will help me clarify a possible misunderstanding from my side and maybe other KP members as well.

Axles with different flexibility (no matter why) changes the “rate of lift”? I mean, do you think a less flexible axle changes the maximun height the inside wheel reach in the middle of a corner? Or different flexibility influences just the position/angle of the outer tire will touch the ground?

My opinion is that yes, different axles change the height of the lift you get, as well as the rate and “spring” of that lift.

Also will change the angle of the outer tire and it’s contact with the track surface.

Thanks for replying @tjkoyen

Your point of view is interesting, but conflicts with mine somehow.

I am a civil engineer not practicing engineering for a while, so I am not the most suitable person to oppose, but I have a different perception.

In my opinion, what influences the height of the inner rear wheel in the middle of a turn is the front-end setup and the rigidity of the frame, besides the driver weight, of course.

Since the axle end at the outer side is not fixed or embed to the ground, the axle should not make resistance to the inner side lift.

Makes sense?

Maybe a drawing like this below I got from Tkart Magazine looking from the rear with those arrows presenting the acting forces would help me to explain my theory

I think I get what you’re saying, and your engineering credentials are certainly better than mine.

I’m thinking of the axle essentially as a torsion bar through the frame, connecting the two side rails. A “softer” axle will allow those two side rails to move more and flex more, giving more lift, or am I missing something?

I got you.

You are talking about the flexion of the axle between the bearings, right?

So, with less-resistance between bearings, frame can twist more. Could I read right your tough?

If it is the case, I read somebody saying here in the KP that the flexion between bearings is minimum and negligible. I tend to agree.

I believe the greatest flexion of the axle occurs between outer wheel and first bearing. From this point towards up to the inner wheel I´d say there is negligible flexion.

If the axle is flexing mostly on the outer end, wouldn’t a stiffer axle flex less there as well, limiting how much the inner wheel side frame rail can come off the ground?

yes

I don´t think so. I think the frame position stays the same and the height of the inner wheel as well. What changes for me is just the angle between the outer wheel and the ground. But I´d need a mechanical engineer to confirm that.

It would be cool to build a static jig to test this. If you could strap a bare frame down, put a seat in it, and measure/apply a consistent force to simulate body weight in that seat, you could just throw each axle in and see how much flex happens at that same force.

In this exercise, where should be forces applied?

I would guess you would want to apply them onto the seat stays/outsides of the seat so it would be similar to your bodyweight moving in the seat during a race.

Obviously the caster and front end plays a massive role in the lift of the inside rear wheel, but specifically here I would want to isolate the axle’s ability to flex.

Or you could put a whole built up kart on a table and just apply constant side load through the seat and see how the axle flexes with caster and the wheel turned too.

Get real fancy and get some strain gauges involved and the data would probably be insanely useful for chassis tuning.

The things I would do if I just had an over abundance of cash.

Yep. A strain gauge would answer a lot of our questions, but I´d need to engage the local university to bring a strain gauge to the track or another option would be to take the kart to the university for tests.

Anybody here has access to a strain gauge and a kart including two different axles in terms of flexibility?