I run 42-43 front. It’s fine.

For me I have 15 degree mount, and XL seat, and a two stroke chassis. So my Lo206 is shifted pretty far so everything fits without rubbing. I also run my clutch outboard, but thats because I really have no choice unless I was to cut out the 3rd barring. Which for me was one of the big draws to getting my chassis, as I can jump between 4 stroke and 2 stroke while running the same chassis (if I choose).

So riddle me this. I’ve heard “rumors” of people using counterweights on their Hilliard Flame, I guess it improves performance?

Some people run weights in their clutch. Most don’t.

I ran into a similar problem to @IRQVET regarding the 3rd bearing cassette location I believe. To get my motor mount centered better, i have to run my clutch inboard to avoid hitting the right seat post with the chain. But that way, even with the motor as far left as possible, the third bearing is in the way. Would it be bad to drill two more holes into my motor Mount base plate so that I can move it even further left? My only other options would be to buy a different motor Mount or go back to how I originally ran with the motor shifted way right and clutch outboard.

What chassis is that. Kosmic?

Yes. With Burris motor mount. Wondering if I should go back to my original set up and sacrifice the main purpose of the original article from this thread lol OR is it okay to drill a new set of holes in the motor mount?

Does the top plate have more bolt holes for the bolts going to the bottom? What if you flip it 180? I think you can get further that way.

Just run the driver towards the seat and set the engine to the right. Don’t over complicate it.

This article is dumb. No one is losing laptime to an offset engine.

There’s about a hundred other things to focus on.

Spoke to two extremely fast guys who make the podium at CKNA do. I’m interested in learning more if its within the ruleset/ legal.

I cant measure any loss on a dyno but I do run mine as tight as I can but its still offset. I am not sure about dynamic losses in cornering acceleration as I have no reliable way to test it.

The biggest advantage I have found to running the driverinboard is that it helps expose more of the clutch to airflow and away from the motor. So in theory it might be more consistant and run at a slightly lower temperature.

I’m not sure the airflow and temperature issue would even matter unless you’re running a dead stop hairpin once or twice every lap?

Yea, I mean at Wilmington dead stop hairpin into a uphill strait kills a Flame in 7 laps for me… so maybe it would help, I just run a stinger there and it holds up fine.

Weights are legal as long as they are OEM and unmodified.

Thanks @fatboy1dh Derek. I pulled it off and found I can move the screw locations for way more variation. @CrocIndy Matthew, I’m leaning toward you being correct that offset is not going to make a huge difference. But I’ve struggled too much trying to get it centered that I can’t turn back now lol.

I want to give an update on my adventure of sliding the 206 engine to the left to minimize right side offset. It has been really difficult on my OTK Kosmic. However, I think it was the single best thing I did to improve my laptimes (for weight distribution reasons).

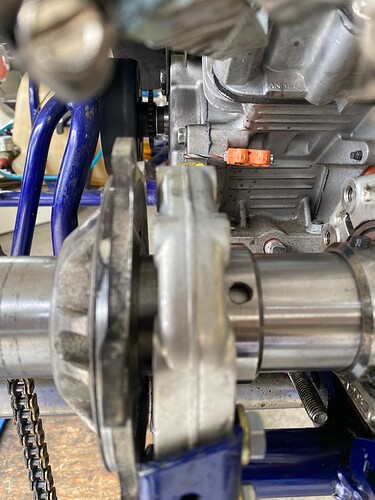

As already mentioned, after I shifted the motor to be mounted as far left on the mount possible, I had to switch the clutch to an inboard configuration to avoid hitting the OTK right seat post with the chain. It wasn’t too hard but was a learning experience for me. Once I did that, I had the issue of the third bearing cassette holder being in the way of the sprocket carrier and I was about to give up. Turns out

I could rotate the base plate of motor mount 180 degrees to get the motor even further to the left which wasn’t difficult but had me perplexed for a while before @fatboy1dh chimed in.

Once I had those first two issues worked out, it was on to bending the left seat post quite a bit to get the seat out of the way of the clutch. The method that @Don_Westlie describes above worked for me but it was nerve wracking to bend the seat post out of fear of it cracking. Do it at your own risk. I also had to get some UHMW material to use as a spacer for the right seat post and now my setup looks very similar to Don’s picture above.

Now on to the stuff not talked about yet.

- Clutch guard hits the right seat post so you have to cut some metal out of it. It wasn’t too bad but makes mounting and unmounting the motor kind of a hassle.

- With the clutch just in front of the right seat post, there is very little room to slide the engine back making sprocket changes more of a hassle. You might say “Just mount the motor further forward so you have more room to slide it back.” However, the rear exhaust is very close to my sprocket guard. I ended up cutting my sprocket guard down to help a little bit but there is still very little play.

- At the track I wanted to adjust rear ride height. Tried to move the axle one notch and had to shave off more of the clutch guard to make room, luckily I had a tool to cut more metal off.

Long story short after a lot of struggle, nothing that was too difficult but did take a lot of time and effort, there was a lot to do to get the motor centered over the motor mount. Like I said at the beginning, it was worth every moment. I was able to scale 50/50 left-right whereas before I was about 54% right-side heavy. The handling difference felt huge (although I did change axles too) and in terms of laptimes, where I was about a second slower than the leader before, I closed that gap by .6 seconds. I don’t think the axle change did as much as the weight distribution change but I could be wrong.

If you have data before and after; The why might be apparent. You should be able see a different time diff plot shape based on whether the gain was through efficiency or better cornering. I would attribute reduced friction in the motor (by moving motor) to efficiency. Transient gains (corners) in time are likely due side to side weight distribution. The axle change could affect either efficiency or cornering. Better efficiency looks like a constant slope on the time difference plot.

Just thinking out load.