I had bought the motor used so not sure how old it really is. The braided wire broke off from the connector. I do prime the fuel line before starting. The brushes had not been replaced yet since there was no silicone added like recommended. And I was more than excited when it worked! I had never done that repair before.

My engine builder gave me this tip:

Put 12v directly to the starter, if it does not spin you know it is the brushes. If it does spin, work your way back. For me, it was the brushes 9 out of 10 times, but this was on a Leopard.

So far with the X30 (knock on wood) the darn thing starts every time.

I think these motors came out in 2018, maybe 2017, but even still it doesn’t seem like the starter would have been used that much to require new brushes after 4 or 5 years of use. I have hand drills that are even older and they spin a lot more than a starter motor.

Regardless, glad you got it figured out and thanks for the update.

The biggest difference with brush degradation on Leopards and the KA / VLR is lack of a balance shaft. The extra vibration induced just shakes the brushes apart. Having shifted from the Leopard to a Rok Gp, I can tell a big difference in the smoothness of the engine as it revs.

I agree with you that brushes should last longer they don’t however.

I’ve probably had 2-3 sets through my motor since I bought it in 2015.

I feel like there is some manufacturing fault in the attachment of the woven wire to the graphite brush material. Anecdotally this seems to have improved over time, but they do all seem to break in the final of a major event.

I have just of accepted that they will break occasionally and $26au isn’t too bad to replace them.

Well I guess i better “brush up” on how to do this!

Mack Truck v. Cadillac

No lie…and the mid range torque is Beastly!! I freaking love this engine. Before on the Leopard I played with gearing to get better torque our of the corner (keep revs up and not lug the motor), now I play with gearing to adjust the timing of the power valve opening and it getting on the pipe between corners. I was finding that it was opening/coming on just before the next corner and not taking full advantage of the power available. Dropped a full second off my lap time at DKC after doing so.

Sorry, back to topic. I would recommend replacing your starter brushes annually (depending on how many hours you put on the engine a year). Its cheap insurance and should be part of your offseason maintenance schedule.

I was looking into this procedure a bit ad looking for advice. The recommended tip is to:

SUGGESTION:

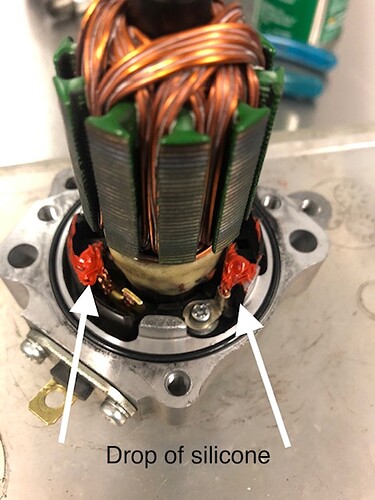

TO IMPROVE THE BRUSHES LIFE, SECURE THE LITTLE WIRES WITH SILICONE (See Fig.19).

However that seems a little generic. By silicon do they mean silicone adhesive or sealant, silicone grease, or something else. I would think they are getting at some sort of sealant but it doesn’t appear they use that in manufacturing? I guess this also verifies the brushes don’t wear out they fail from vibration.

On my X30 starter I kind of coated the wire along the whole length with silicone sealant. I put extra on the end where the wire usually fails. I assume it helps dampen the vibration and keep the end of the wire attached longer. I did it a year and a half ago and haven’t had a starter problem since.

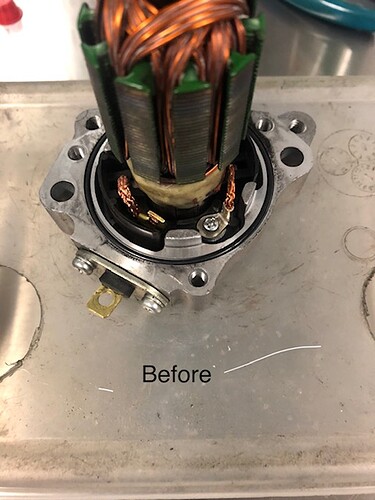

I will post a picture of what to do tomorrow. You can use any silicone based liquid gasket or adhesive, I just use cheap, red high temp RTV, works fine.

Thanks for the pics. Just to clarify… are you trying to just coat the lead or coat the lead and attach it to the housing in some way?

You want it to stick to the housing, the goal is to keep the lead from vibrating, having it attached with a little silicone buffer just keeps it in place.

@Awa here you go. 29 karts