No reason to miss the KT, they’re still in production.

Sorry, i mean i miss racing those. There isnt a class for them anymore at our club.

That’s a shame really, It’s happening more and more and IMO isn’t good for the sport.

I completely agree Greg

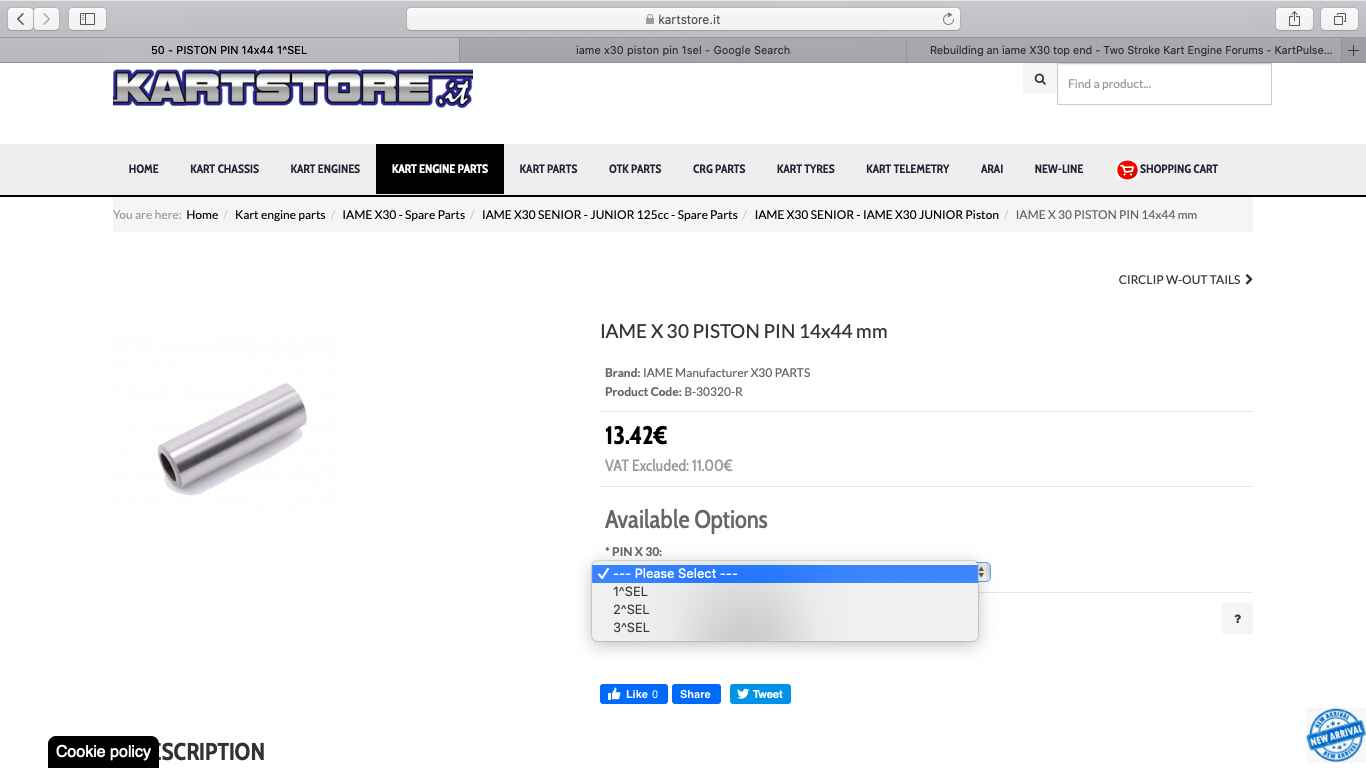

Gents I’m trying to order new piston and pin from Kartstore. Any ideas what does 1sel/2sel/3sel relate to?? Can’t find any info

Cheers

Ric

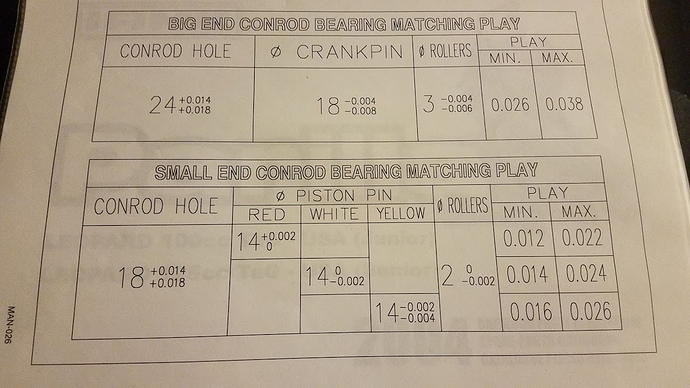

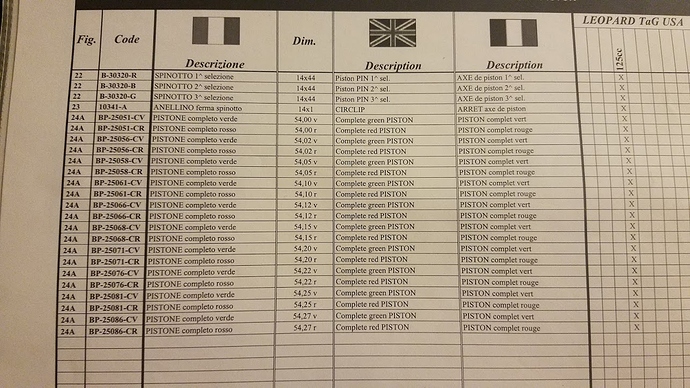

Iame makes 3 different pin sizes, red (1^), white (2^), and yellow (3^). White is the standard 14mm size, the yellow is .01 undersized and the red is .01 oversized. They make these to accommodate for slight variations in the pin bore of the pistons. There should be a painted dot on the underside of the piston in the color of the pin you will need for that particular piston. Most pistons have a white dot. I always use white or yellow, the red are too tight on most pistons. You should not have to really force the pin through the piston, it should slide through with a moderate push.

Thanks for that, crystal clear. So I have to wait for te piston to arrive to know which pin I need

I’ll order a white and hope they match lol.

Cheers

Ric

So just revisiting some information.

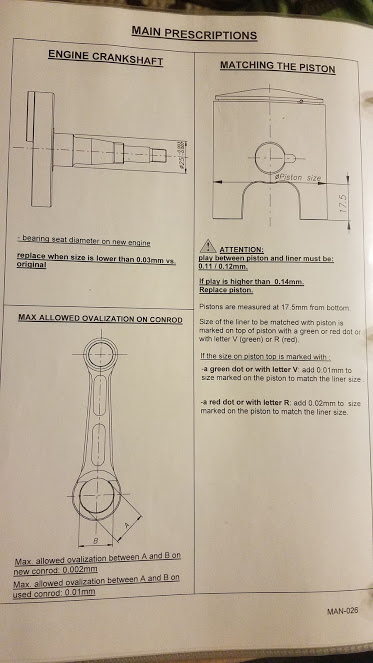

Assuming one has skill and tooling to hone cylinder is their any reason not just hone and re-ring regularly for club racing if piston is within spec to keep up top performance?

No, not really, though you’d likely be replacing the piston before performing a hone if opening it up and throwing parts at it for top performance. The piston wears out first (aluminum), then the steel bore.

As long as you inspect the piston regularly for cracks and track the time on it.

Problem is that beyond skirt wear, the concern is piston failure. When it happens you don’t get much warning and it more-or-less takes the motor with it. It’s also not directly related to skirt wear either.

Over time the bore shape gets irregular, that’s one of the reasons behind honing it. Generally there still a good cross hatch pattern to bed in a ring.

So you could just throw a ring in and see if it makes a difference in performance.

James

More or less what I was wondering. Trying keep max performance thru routinely replacing a fairly inexpensive ring and extremely light hone for cleaning and re-seating ring versus going longer interval and doing both.

Of course inspecting, measuring and then replacing piston at recommended intervals in service manual from Iame to avoid failure.

Do i need to dissasemble the case to check this??

Al passed away a lil while ago, fyi. Maybe someone here can pinch hit for him.

Oh noo😭 now i feel bad for texting a dead person. RIP alvin

Nah, Al would have enjoyed it.

This is done with the engine assembled.

There are some good videos on Remo Racing’s (the Australian IAME Importer) website on how to check the clearances.

https://remoracing.com.au/iame-engines-m/iame-x30-125-tech-info-downloads