I have questions about Aixro power and how the engine power curves are measured. I’m starting with the situation and setup description. The questions are at the end. Skip to the message end if you prefer.

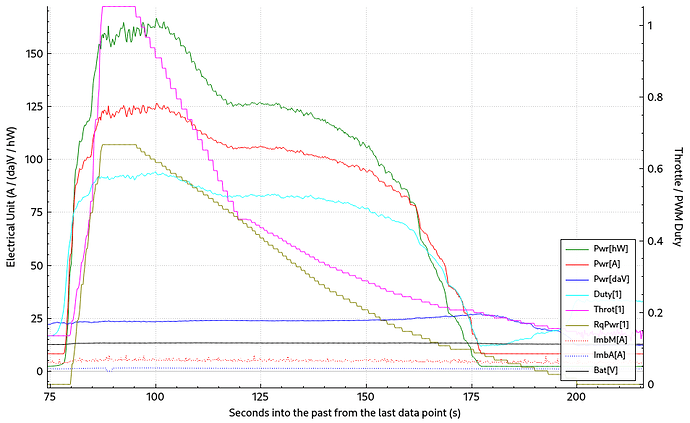

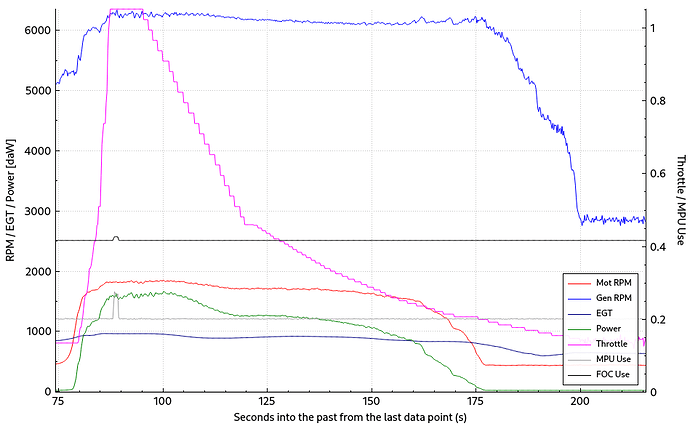

I connected Aixro XF-40 to an electrical generator and tried to check the maximum power I can get from the engine. My target is to get about 10-14 kW for a long sustained run and at least 20 kW for a few minutes. Maximum time may be limited by main bearing temperature. My problem is that I cannot pull more than about 16 kW from the engine. E.g. I reached 16 kW at 6250 RPM. This happened when the throttle valve (in carburettor) was opened at 63 % and the peripheral port valve was opened at 28 %. Opening carburettor or peripheral port valves more is not helping. Power at the same RPM is not rising when opening the valves more. The only effect is that EGT is dropping a bit sometimes (indicating a richer mixture). Based on the official RPM-power charts of Axiro I’m missing about 5.9 kW of power at 6250 RPM.

I’m adding some charts for one of these 6250 RPM runs. Aixro RPM is labelled as “Gen RPM”, carburettor throttle valve opening corresponds almost precisely to the value labelled RqPwr. The value labelled Throt is actually sum of carburettor throttle valve opening and peripheral port valve opening.

I tried to do a lot of similar tests at about 5300 RPM where I’m missing about 2.8 kW in my experimental measured data compared to the official RPM-power charts.

In general it all looks the same. Adding more throttle (while generator load is not allowing Aixro RPM to increase) is not helping after reaching the power limit of about 16 kW on RPM 5000 and more. This upper power limit seems to be there regardless of the Axiro RPM in the range from 5000 to 6400 RPM. I did not try higher RPMs than 6400 yet.

Setup:

Aixro XF-40

Bing 84 carburettor

100 octane gasoline (100 octane used since it should be without alcohol)

2T motor oil mixed in gasoline (gasoline to oil = 50:1)

a permanent magnet generator connected to Aixro with a timing belt

a controllable load on the output of the generator; the load makes sure Aixro RPM averaged over one Aixro shaft revolution is stable

The mixture seems to be about right based on the spark plug colour (reddish-white). Compression is OK based on turning the engine by hand. A new oversized air filter is not helping.

There are 2 differences when compared to a standard application where Aixro is connected to a cart back wheel shaft or to a propeller:

- Mass moment of inertia of the generator and the connecting pulleys is only about 0.0484 kg.m². This is much lower inertia than a whole go-cart can provide and significantly lower than a propeller (with a transmission) provides. The result is a significant RPM variability within one Aixro rotation. The variability is about 350 RPM peak-to-peak. I.e. Aixro shaft is rotating about 350 RPM slower during ignition than it is rotating at the end of the power stroke.

- Carburettor is connected to the inlet manifold using a 9 cm long rubber hose.

My questions:

Can point 1 or point 2 in the previous list be the reason why the output power of our Aixro is limited to about 16 kW.

What else may be wrong?

What kind of dynamometer is typically used when generating cart engine power charts (like Aixro)? Is it inertia sweep dynamometer?