Why have higher powered karts moved on from 40mm axles to 50mm axles? What changed?

It’s a good question. Considering 90HP superkarts run 30mm axles it’s interesting.

I recall the first 50mm on the Tonykart extreme in 1997. There might have been some before that, but that’s the first I remember and then it quickly become the norm.

CRG trialled a 45mm for a while, it ultimately stayed on 50 for junior and senior classes.

I think it may have to do with tunability. The 50mm axles have a lot of different stiffnesses, but the 30mm have less. Looking at the OTK stiffness chart, they have 7 50mm axles, 2 40mm, and 3 30mm. I assume there’s less tuning for a cadet kart compared to a senior but I wouldn’t really know.

As far as superkarts go, I think it’s the same principle. Since they run on road courses, mechanical tuning with the axle is probably less prioritized than a sprint kart.

Interesting! I was wondering if chassis design or material has encouraged the change as well, but I wouldn’t have a clue as to why in that aspect. Axle stiffness variations makes a lot of sense though.

I remember when the big “switch” happened from 40mm to 50mm and we did some back-to-back testing on them.

The medium 50mm axle felt more stable than the medium 40mm axle, in junior/senior KPV trim.

Took me a while to find where I had posted this on another forum, but in the end its from Comet Kart Sales anyway. I think this accurately explains the determining reasoning.

“Older designs were generally stiffer frames and to free it up we needed to soften the kart as much as possible, newer models are softer overall and transfer weight differently. So putting a stiffer axle in some of the newest models allows the kart to transfer weight better, it’s less of a “wet noodle” with a stiffer axle. The softer axle just increases chassis flex even more and the kart doesn’t transfer at all. It’s another way to do the same thing, unload the inside rear of the kart, but you seem to run out of softer axles a lot quicker trying to free up a stiff kart than harder axles trying to free up a soft kart. As I mentioned earlier, this seems to be more of a 50mm axle phenomenon than a 30mm or 40mm.”

It’s my belief that in the 90’s chassis were stiff and axles were soft (30 or 40mm). Tonykart realised they could be faster and have a more simple chassis setup if they went with a softer chassis and a stiffer axles (50mm). For years the others just went to a 50mm axle without making the required change to the chassis. I believe ART worked it out second, and took that knowledge to BirelART which is why BirelART suddenly popped up in rotax.

My understanding is the chassis material is somewhat more expensive then before and it doesn’t last as long which might explain why other manufacturers didn’t jump to it. It also seems to not have as much an effect if you increase power and weight (KZ=>250) or maybe it really doesn’t even last a weekend in those classes.

My issue is that “Soft” and “Stiff” are very subjective terms that are close to meaningless. It also doesnt account for dampening\rebound (for lack of a better term).

I’m not convinced axles actually flex, given that the softest part in that system is your tire. I’m not saying axles and hubs don’t make a difference. They do. But as to why… I’ve yet to see any actual evidence where someone measured axle deflection, and or chassis stiffness is a meaningful way.

Honestly, I agree with you. I can’t work out the math for axle differences. I can’t think of a time I changed an axle racing. Even when i raced for TopKart and CRG in Europe, we never changed an axle and my racing has been too sporadic and cheap in recent years to change an axle.

One day I will test because I’m just not going to trust anyone else. I definitely struggle when a driver goes 8 tenths slower because we changed an axle.

But for sure, soft and stiff are the wrong terms. Springyness?

Exactly this. I also have heard/pushed this theory a couple times too when the question “why does OTK put a hard axle in to free the kart up and everyone else puts a soft axle in?”

My thought is:

Soft chassis + stiff axle = chassis flex and lift…?

Stiff chassis + soft axle = axle flex and lift…?

Hard to say what is really going on, as you and James both touched on, as axles are so hard to quantify.

We never changed axle on our ART and we very rarely change axles in the OTK.

On the Merlin, “green” was the standard axle, “yellow” was hard, “white” was supposedly the same “stiffness” as the yellow but a different material. I don’t know what was different but I know I definitely felt a difference between the two. The yellow was springier it felt like. The yellow made the kart hop and the white made it settle back down.

When I was wrenching for some Merlin guys several years ago, we always ran the medium axle. If the kart was off, me and the dad would look at each other and go “we probably should change an axle… But that’s a lot of work.” So we never changed them. Screw axles. I’d rather play with the other dozen adjustments on the kart.

I only change axles to show off my wrenching abilities

I haven’t actually wrenched for a year or so, I have been banished to the trailer to be engineeringy but a couple of years a go I bent the crap out of my fingers on the Thursday I did the rest of the week basically one handed.

But at the Rotax Grand Nationals last year we changed the axle for qualifying and the driver lost 8 tenths. We all knew there was no way the axle did that but we had to change it back for “head” reasons.

“Head reasons” is the number one detriment to successful kart tuning.

I remember a few years ago, another driver in my class had dropped a wheel or something while leading and it cost him the race. When we asked his dad what had happened, he goes, “We couldn’t find the tool.”

“Tool? What tool?”

“The one that removes the driver’s head from his ass.”

I am often looking for that tool myself.

I think a test would be interesting to see the flex rating of the axles and how they change the kart. Flex rating is something I’m familiar with through hockey, but basically the number would stand for how many pounds it takes to flex the shaft of a stick one inch. I’d love to see what the flex ratings of an axle are.

A test would have to be basically “We’re gonna run a time on an axle, and then change the axle (or not) and send the driver out again to see how times compare.” Driver doesn’t get to know what’s changed, but they have to drive the kart. I’d do this myself if I actually had the time, resources, or skill. Oh well, maybe with time I’ll find myself in the situation to try it out

I’ve heard people testing flex ratings on axles and the ones they tested were all really similar even though they were supposedly different stiffnesses.

I wonder if that means it doesn’t take much to have an impact on chassis handling, or if everything in an axle is psychological now

I think i’m right in thinking just deflection will not change for a given diameter and wall thickness. Generally speaking with a steel you can only change the ultimate strength. The point of the elastic region doesn’t change, just the yield point. So hardening an axle won’t change its deflection but it might change it in the strain hardening region.

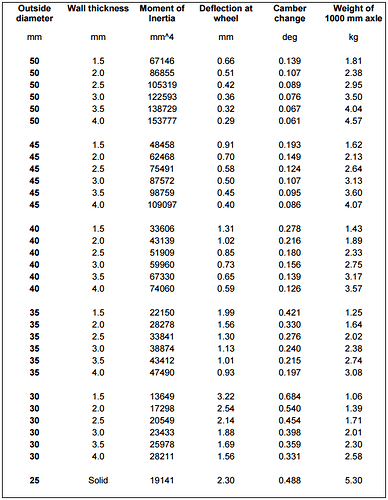

From “Karting Magazine”.

A very important engineering requirement is to be able to characterize the cross section of a part of a structure or machine to establish if it is strong enough in terms of failure or deflection. We all know that it is easier to bend a ruler when it is flat than when it is on its edge. This tells us simplistically that a deeper cross section is stronger than a wide cross section. From applied mechanics, each cross section can be analysed for its shape and a number can be calculated for the shape and size of the cross section. This is called the Moment of Inertia, for which the larger the number the stronger the structure. For round tubing, the formula to calculate the Moment of Inertia (I) is :

I = 0.049(D^4 – d^4) where: D = the outside diameter in mm

d = the inside diameter in mm.

For a 35 mm axle of 3 mm wall thickness, the value of I would be 38,875 mm^4.

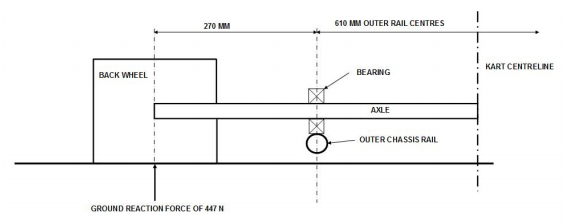

In engineering design, it is essential to know and use Young’s Modulus (E) and the Moment of Inertia (I). In conjunction with the known load, we can calculate the stress on the material and also how far it will bend. If the calculated stress is too high, the design must be modified to bring this within acceptable limits and/or factor of safety. Let’s consider the static loading on a back axle of a 160kg kart. Assuming that it has a 57% rear weight bias, than the load on the rear wheels is 91.2 kg and if the loading is equal, each wheel will see 45.6 kg (447 Newtons). The chassis has its outer frame rails (and bearings) at 610 mm centres and the track is 1150 mm.

From the above situation, we can compare the stress in the axles and the deflection at the wheel. In doing this, we must acknowledge the following assumptions for simplicity:

- The axle extends to the centre of the wheel

- The length of the rear hub is not taken into account

- The sprocket carrier is ignored

- The axle is essentially rigidly clamped inboard of the bearing

- It is a static loading

Going back to basics, it is very rare that an axle will permanently bend in service. If it does it will either be due to an accident or, in the case of very thin wall axles, kinking to due overtightening of the grub screws?? So, on the basis that the axle runs true, the only way that the axle could affect the kart handling is the actual deflection or flex of the axle under the fairly complex series of loads it undergoes during cornering. This deflection can influence the overall chassis deflection and importantly can alter both the camber and wheel alignment (rear wheel steering) of the two rear wheels plus the road contact pressure of each of the two wheels. These factors will influence how the kart handles in a given situation.

With reference to the loading on the axle, we can use the following formula to calculate deflection (S) at the end of the axle, which will be the deflection of the wheel.

S = (L * F) /(3 * E * I)

where:

L = load in Newtons

F = applied force

E = Young’s Modulus

I = Moment of inertia

The following table shows the deflection of a range of axle sizes and wall thicknesses. Also included is the change of camber of the wheel from its vertical position at zero load.

The significant number in the above table is the Moment of Inertia. If it is the same for two different axle types, then the deflection will be the same. A few examples of this are:

- a 50 mm * 1.5 wall axle is approximately the same as a 40 * 3.5

- a 40 mm * 2.0 wall axle is approximately the same as a 35 * 3.5

Which one is the best? Like many things with karting there is no clearcut answer, but the following may be considered:

- If weight was critical, then the larger axle might be regarded as the one to use as it is lighter. Offsetting this is the greater tendency for the thinner wall axles to kink (permanently). Because of this and if weight wasn’t an issue, then the smaller size axle might be considered the one to use.

- If your mild steel axle wasn’t failing, there would be no benefit to going to a stronger material.

- The above argument and comparison indicates that ALL axles of the same diameter and wall thickness will act the same (ie, your mild steel axle will be exactly the same as a chrome moly axle). The sole reason for the use for stronger materials is to gain a greater resistance against permanent deflection (bending).

I am sure that the last two points will be argued against by many, but after all this is just a perspective and it must be repeated that many assumptions have been made.

As for the original question, stronger axle that’s lighter than the smaller diameter Axle??

It does look like weight is a part of it, which is important. Since the axle rotates, it takes more work to get moving than a static object. Not only are you changing the velocity of the axle, but also the rotational speed of the axle.

There’s also moment arms and stuff that goes into those factors but I would guess that lightweight has more of a factor there than the distance from the center.

There is a thread on the Kartbook Forum about axles. If you have a spare- I’m not going to nominate a timeframe, and want to be even more confused about how axles work, or don’t work, head over and check it out I think it is up to at least 11 pages now.

Long and short of it was, several people tried to test axles for “Stuff” and no test they did could get consistent results and on and on and on.