Hello folks,

On picture you can see brand new spark plugs after aprox. Uploading: 8031_1_spark_plugs.jpg…

Hello folks,

On picture you can see brand new spark plugs after aprox. Uploading: 8031_1_spark_plugs.jpg…

What’s the white sealant looking material on the threads?

Hmm didn’t see that  surely it would degrade the plugs ability to transfer heat to the head.

surely it would degrade the plugs ability to transfer heat to the head.

Do you think if it wasn’t transferring heat it would look more lean? I.e. burn off more of the carbon?

What engine? (Looks like a 4cycle to me)

How much time on the plug?

What was the engine load?

Just running on a stand?

Full race track load for 10 ~ 15 laps?

What’s the carb setup?

Looks rich on a cold engine.

Looks like pipe thread sealant to me. Yes, it can have an effect on the heat transfer, but the question is more of why is it being used.

Are these from a 4 cylinder motorcycle engine?

Rotax914 aircraft engine.

20 - 25 hours.

Running status, saw after flight.

Fuel: 100 LL

4 stroke , 4 cylinder. Rotax 914 engine.

sealant is necessary in case of aeroplane flight.

Curil T Sealing Compound - the non-hardening, temperature-resistant sealing compound from ELRING:

excellent sealing effect even at extreme temperatures (up to +250°C), Ideal for flat, finely finished surfaces, particularly in internal combustion engines, exhaust-gas turbochargers, gearboxes, turbines, generators, threaded connections and many other applications.

Ahhh airplanes different. I dunno much about GA engines other than I’d expect all plugs to look similar. Give me a gas turbine I’ll bore you to tears

Many Rotax engines will have black sooty plugs at times from idling at the lower rpms. That goes away at cruise rpms. That mixture can be adjusted slightly, but it usually isn’t that big a deal. The carbs should always be synced at idle and the upper rpms (i.e 3500), this is very important and don’t neglect it. I sync all 912 engines every 100 hrs. If you have a ground adjustable prop it should be set to get at least 5500-5600 rpm WOT flat and level and at your average cruise altitude. Then you should be cruising at 5000+ rpm and not the mid 4000’s. All this comes into play. The length of service time on the plugs and the gap makes a difference too. The plug gap range is .023 to .027. Use the smaller gap for the cold winter months and the wider gap for the summer months. Don’t leave plugs in service too long. I change mine at 75 hours and others at 100 hrs., but I wouldn’t go over 100 hrs. If you can’t get up to operating temps then use a piece of 2" wide aluminum tape across the coolant and or oil radiator. If that isn’t enough because it’s real cold add more until the temps come up. Unless there is another problem at play most of the time these few little items can make a difference.

Assuming you have a carb running 1/2 and another running 3/4, I’d say they’re not synced.

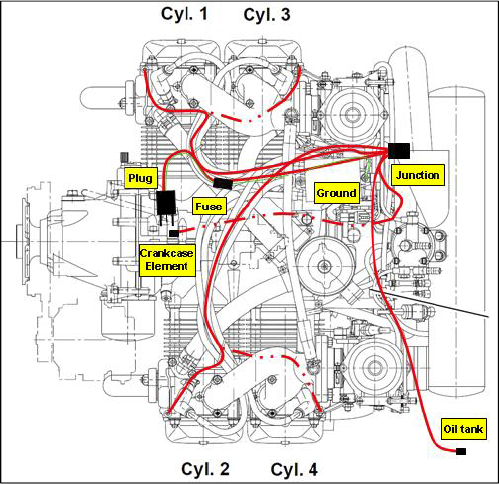

@Richard_Jacques went into much more detail. I looked up a 914 and noticed it has two banks… are the two dark plugs from the same bank?

1-3 at one side, 2-4 at one side.

So you have 1/3 and 2/4 supplied by different carbs. Are you sure you got the numbers correct in your first pic?

Double check and balance the carbs.