Hot off the press today, as hinted on our KartPulseLive show a couple of weeks ago, some updates have been made to the measurement process for the Briggs 206 Head gasket.

~James

Briggs & Stratton 206 HEAD GASKET Rules Set Reminder and Update

As we move get into the 2018 race season there is a downward trend in the thickness of our head gasket when measured new that we are aware of. Although the final compressed thickness remains linear the slight increase in graphoil density and field samples have led to this reminder and update.

After further investigation we have recognized and identified the following factors:

The graphoil density in the pre-compressed secondary around the outside of the gasket shows .001-.0015” more squish than nominal. With the engineered crush of the gasket around the combustion chamber (to promote sealing), this area too will trend .001-.0015” lower (linear).

In the official 206 rule set the use of a micrometer not a dial caliber is called out. This is to help eliminate the inherit variance of thumb pressure and perpendicularity when using calipers. While a caliper can be used for a quick check (as called out in 4e.) a micrometer is the official measurement method.

We would also like to remind our racers that our MAXIMUM recommended head torque is 220 lbs-in. Increasing head bolt torque beyond factory setting will increase gasket compression. Fasteners and gaskets are engineered as a system for maximum joint strength, more torque will not yield any improvement. Also, never set torque or check the torque of any fastener when the engine is above ambient temperature. This will lead to a higher than specified torque setting. Lastly, always use a quality, reputable brand torque wrench to insure accuracy.

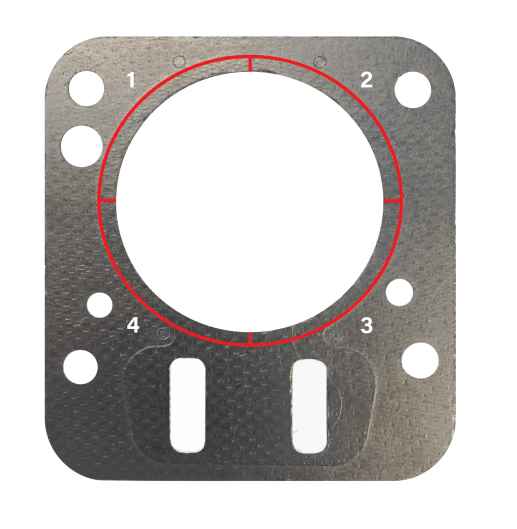

Finally, to ease any field concerns the minimum thickness will adjust from .049” to .047”. We are also implementing measuring in the 4 quadrants around the combustion chamber verses specifying the head bolt location (typically an area of slightly higher compression).

The updated rule reads like:

- Head Gasket (updated 4/10/2018)

Unaltered B&S part #555723 is the only head gasket allowed.

Minimum thickness allowed is .047". Measurement must be performed using a micrometer. Readings are taken from inside the cylinder hole of the gasket closest to the combustion chamber (see diagram). Four measurements must be taken in the four defined quadrants with 3 meeting the minimum thickness of .047”.