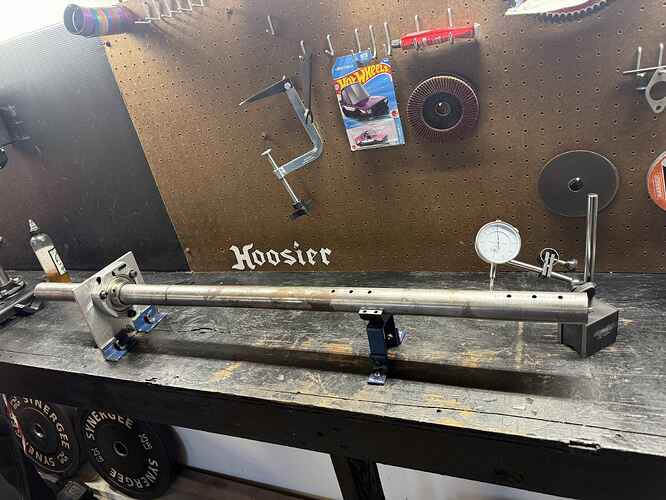

I run a team with a very tight budget and I got tired of spending over $200 to get all of our axles straightened (we could also try not bending them in the first place but that’s another conversation). I had an extra bearing hanger, some flat aluminum, bearings and an old upright stand laying around. After a bunch of cutting and bending I ended up with this. Took a PKT wide axle collar and used that as a u-channel for the axle to rest in. Then I’ll come up with a way to attach the other half of the axle collar to a bead breaker. Clamp the bead breaker to the bench and bend away. I’ve already tried with a very slightly bent axle and just using the bead breaker as it is, and it worked well. Will update with photos once I attach the collar to the bead breaker.

8 Likes

![]() Where’s the fun in that tho?

Where’s the fun in that tho?

Very cool idea and execution. Let us know if it works as you hope.