Thoughts on ceramic bearings?

What do you lube them with?

What do you line your steal bearings with?

Personally, I think they’re snake oil. Some people swear by them, but I’ve found zero difference in rolling resistance, at least on a TaG kart where you’re limited by the o-ring chain. Maybe there’s some benefit in a lower horsepower kart, but for me they aren’t worth the money.

Regardless, we always lube bearings with Tri-Flow between sessions. We used to have a whole process for packing the bearings with lube when we tore the kart down after a weekend, but it was more work than it was worth in my eyes.

They are actually worse for friction in our environment. I have not seen one with C3 clearances yet, hence tighter tolerances and more friction. plus you have to have contact seals to stop muck getting in. Again more friction.

So yes snake oil indeed.

I feel like if they were that much better, you’d see the top teams in karting using them exclusively.

My take on them and other high dollar items that are unproven:

By 2 sets of the proven technology and have a spare. If you have the money then you can afford to buy the ceramic and a set of steel spares.

On steel I make two half circle cut outs in the shields. I orient them @ 12 & 6 O’clock. I use them to flush and lube. Plus if you need to pop the shield of it is easy.

That’s because added performance is not the main benefit. A properly lubed steel bearing with the proper clearances will perform just as well.

The particular material properties of ceramic—

high strength, high hardness, high corrosion resistance

and low density—allow higher operational

speeds and temperatures of the bearings and reduce

their weights. At the same time an increase in life

can be attained since heat generation, material

stressing and bearing wear are reduced and corrosion

can be entirely excluded as a failure mode

(Fig.3)[14].

This is why I like this forums. Logic.

What was the conclusion @The_Karting_Channel

That paper is just a review, so no conclusion.This one is good too, and actually compares to traditional bearings:

Rolling Contact Silicon Nitride Bearing Technology: A Review of Recent Research

Ceramic bearings FTW.

In that case I would say they are a worthy investment if you plan on keeping a kart for like 3 years, because I’ve never had an issue with bearings wearing out, even on karts that are a couple seasons old.

I have seen other people have to replace bearings, but that’s mostly because they spend a lot of time in the dirt and not a lot of time cleaning and lubing their kart.

In conclusion (in my opinion), as with most things, take care of your sh*t properly and you shouldn’t need to invest in fancy bearings.

Oh and another thing, if you get the SKF ceramic bearings, I will never work on your kart. And if I do, we are never changing axles. Those things are a massive pain to deal with, especially when your driver bends an axle and we’re hustling in between sessions to fix it.

It’s a matter of application:

Are ceramics better then properly lubed steel bearings? Perhaps, if slightly.

Are ceramics significantly better then properly lubed steel bearings? Yes, but only in very high speed applications, or applications subject to low lubrication or temp abuse.

Is a kart axle a very high speed application, subject to temperature abuse or low lubrication? Unlikely. But most karts have bearings somewhere else that would greatly benefit from ceramic materials.

I’m not sure if we can consider a kart a high speed application. 156MPH = 3600 RPM for a typical kart size tire. Doesn’t seem like a high speed IMO.

Most kart axles are barely seeing 1500RPM (66mph).

I guess it depends on the industry definition for “high speed.” I don’t know what that would be.

True.

Looking at this table, the lowest max RPM specified is 60K RPM. I think we can consider kart chassis bearings to be low speed.

All the limits shown are based on static oil lubrication, with the oil level set at the center of the bottom most ball or roller when standing still. If grease lubrication is desired, then the speed limit is 66% of the oil limit.

Maybe someone can do some math, I’m not good at math:

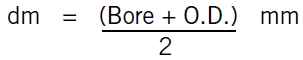

To Calculate the bearing’s Pitch Diameter (dm) from this formula:

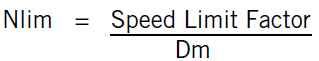

The limiting speed, Nlim, in RPM is simply calculated:

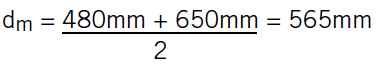

Example Calculation

An NU1996MC3 bearing (480mm x 650mm x 78mm) needs to operate at 800 RPM with static oil lubrication. Is this acceptable?

The bearing’s Pitch Diameter is:

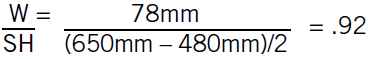

Its Width to Section Height ratio:

This is a narrow Cylindrical Roller bearing with a machined brass Cage.

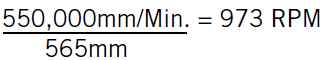

Its Speed Limit Factor is 550,000mm/Min., from Table II.

Its limiting speed – Nlim =

Don’t forget to multiply the result by .66 for grease.

Waste of money pure snake oil. Buy quality japanese bearing for 1/10 of price and be done with it.

Marginal difference in this see video…40,000 rpm .21 engine 2.5 hp

When we ran them and when they did fail balls exploded into million pieces. Failure rate was higher and more catastrophic with ceramic versus steel.

I can not see any possible rational reason to use them in a kart unless you have stack of bills to burn.

What are you trying to show with the videos, exactly?

Just that bearings are waaaaay more stressed in very small diameter and no sigificant performance difference in steel versus ceramic.

The bearings are tiny in comparison to kart and are much higher quality precision bearing (abec rating)

Large scale low speed/rpm like a kart a ceramic is 100% waste of money.

Figure good visualization of how stressed bearings are in comparison.

And lastly that I had practical experience that shows ceramic are waste of money even in small, high rpm, high stressed application.

I get that, but the videos just show an engine on a dyno. It’s not a comparison of ceramics vs steel bearings, no performance comparison, show nothing quantitative.

Your post comes from experience and is very valuable, but it’s ultimately anecdotal. No?

Speaking of bearings. What’s everyone’s preferred way to clean and lube them? Arizona’s a rough environment and I feel like it’s an uphill battle around here.

The fact that “Arizona road dust” is a standard for abusive wear testing in various industries, the out look is not good. From my latch design days, best thing you can do is to keep your bearing as shielded as possible and keep the grease on the inside. Do not allow any grease to build up out the outside and keep the outside clean to prevent build of more dust/dirt. If you allow it to sit there, it will work it’s way into the bearing. That “Arizona road dust” is nasty stuff.

http://www.powdertechnologyinc.com/test-dust-contaminants/test-dust-history/

They are great for… turbocharger bearings.

For karts, I wouldn’t bother.