I’ve only ever used standard chain or belt drive. Now, I’m about to start spinning some o-ring chain, and, apart from not being able to resize it, any other difference in the care and feeing of an o-ring chain compared to a standard chain?

Sincerely,

Chained N. Bound

Never mind. Apparently my internet search skills weren’t doing so hot at the time of the post. I looked again and have since found the info. Cheers.

Do tell. What did you find out?

Probably a little off topic, but are there any real benefits to running o-ring chains on karts?

Coming from dirt bike background and having used them in the mud and dirt for hundreds of kilometres at a time, o ring chains made sense. But i dont really understand why you would on a comparatively clean, closed bitumin track where you have ready access to a service area, cleaning facilities, time and lube etc etc.

Sadly, I forgot to bookmark the page I found and was well written and succinct, and I’ve grown search-disabled again, but essentially the rule is to not clean it with any gasoline, kerosene, or anything else that will eat the o-rings.

I think of it this way: All those things you said are true, but the chain that’s used in dirt bikes is typically the larger chain like in the shifter. Because of the nasty gear ratios we have to run in the single speed categories, we have to run the delicate 219 chain. Because the chain is anything but beefy, there’s still plenty of debris and a typical sprint track to work its way into the rollers and eat it up. In a lower horsepower category, it’s not a really big deal. In a TAG, the o-rings help the chain from tearing itself apart by keeping debris out and lube in.

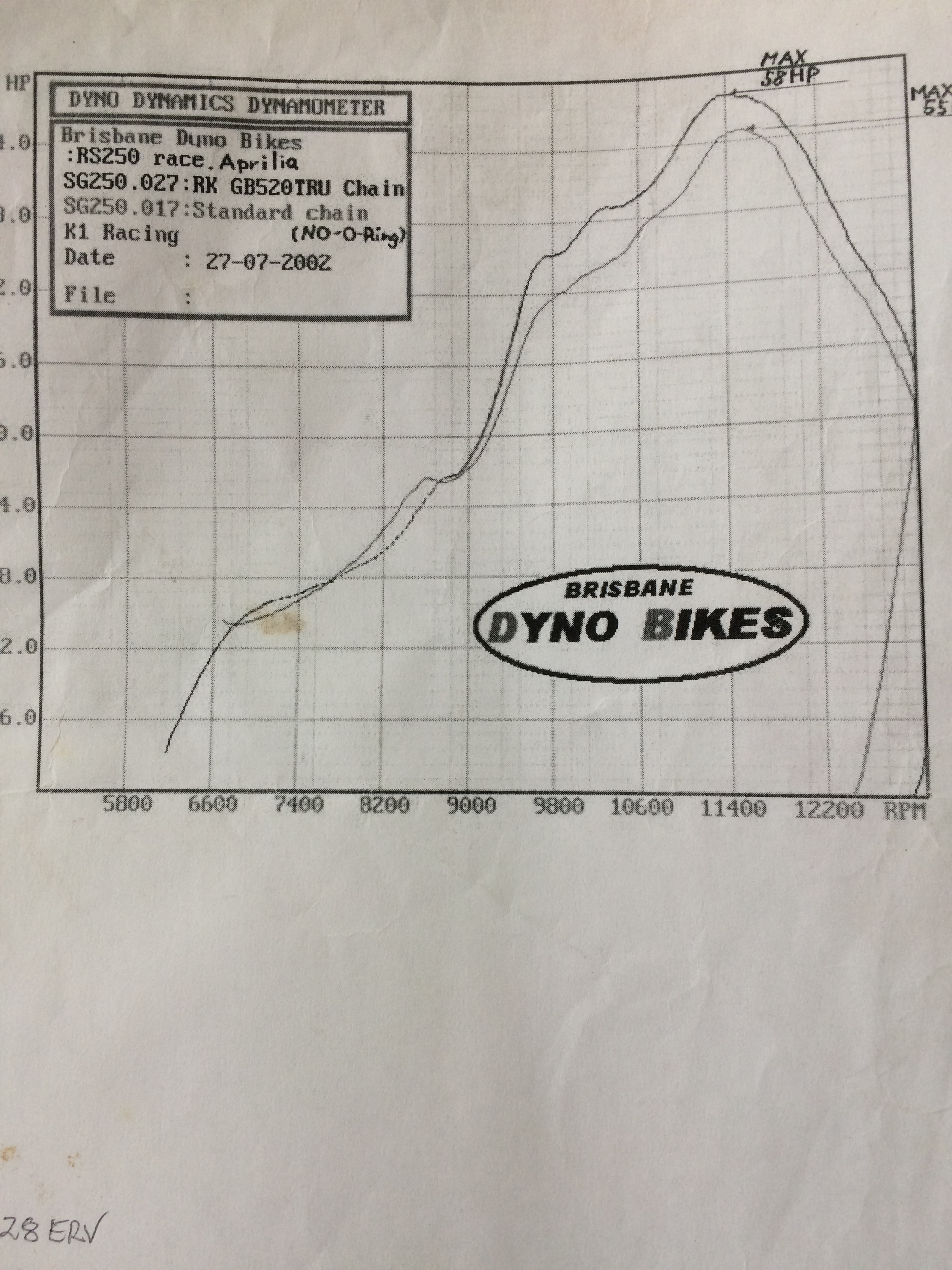

Some say that power is robbed by the stiffer o-ring chain, but o-ring chain manufacturers have stated that dyno tests indicate that once the chain warms up, there is no loss. I have yet to test this claim in my dyno that does not exist.

When running anything with TaG power or more, you basically need an o-ring chain. My experience has been that a normal 219 chain will last a weekend (or less) on a Leopard or X30 engine.

Not only do you almost completely eliminate the risk of chain failure by running the o-ring chain, you also don’t need to replace nearly as often and you can run close to a season on a chain depending on how many races you’re doing and how well you clean and maintain it.

Old, but from a source I believe reliable.

Not quite apples to apples. The dyno’s of a 250cc, which then should be using a 415 chain, right?

Correct, but better than nothing.

If someone can supply equivalent for sprint kart chains - happy days.

Cool, thanks guys. Always learning

I was involved in some testing some years ago to determine power transmission curves for chain drives. This was a military project at lower RPM applications than we use on the typical kart. Open drives were the subject, so the basic data should be relevant. It was surprising how efficient a clean, high quality chain drive actually is when it is within its manufacturing specs. It was approaching 95% after reductions for some parasitic loss factors… However, the loss due to wear and stretch were immediately apparent, and pin to link wear was the issue. Sprocket wear increased rapidly in reaction to the wear and visa V. With that said, it makes sense that o-rings, if they keep factory lubrication in and foreign particulates out, would have to be a great advantage to the life cycle of the chain… I wish we had it back then.