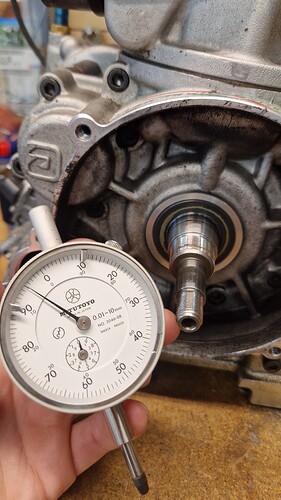

Hello. I want to check my crank and identify my bearing on my testing engine. Anyone knows hot to do it? I have a guage and i dint know how to do it…

You have to build something that bolts to the engine and you can have the gauge on.

This way you can check play. But why?

Are you looking to measure end float (side-to-side) or axial (up/down) play.

Identification wise, you can probably get that from the manual. There’s a lot of interchangeability between engines, they essentially use the same bearing in a lot of cases.

Bc i want to know the tolerance of the cranc id i need to do a bottom end rebuild…

That’s not going to tell you.

Axial play isn’t going to tell you that. Keep notice of how many hours the bottom has instead ![]()

But if the axel has to much play i need to do a rebuild bc i have to balance it on the bench… I have around 15hr on bottom and around 5 hours on piston.

Mike, the critical item in a crank is the rod, or better the group rod/pin/spacer/needle bearing. Excess play in the rod (not side by side, I mean through the working axis) is not measurable with engine on (at least that I know of), if you can feel it means you are way past danger zone, it’s shot and you got lucky. The process requires opening the engine, disassembling the crank, measuring signs of wear, ovalization, overheating etc of all components. Then at minimum you change pin, needle bearing, spacers and keep running the same rod for more hours if it’s good. The crank per se (the two journals) don’t normally go out of alignment and the whole group can have play if bearings are shot, but that is a bearing issue. There is a way to measure crank alignment when engine is assembled, but that gives you a different piece of info and it’s done with new bearings anyways, so it’s not a test to tell you whether or not you should do a crank rebuild.

When you say “axle has too much play” what do you mean exactly?

I assume you meant axial, That should not change regardless of wear. You are looking at it wrong.