I have an iame leopard 08 engine. I am putting the clutch assembly back together and when I tighten the outer bolt on the clutch drum it doesn’t move free anymore. What could be the problem where my clutch drum doesn’t spin freely.

The spacers have a bevel on one side, it must be facing the correct direction.

Should the bevel be facing towards the needle nose bearing for the clutch drum. Basically the needle nose bearing sits in the bevel of the washer? That may just be the problem.

Bevel faces the block, then needle bearing, then (maybe an oring) and clutch bell.

There is no o ring. that’s how I have it where the bevel is facing the block or towards the engine or where you would be sitting

Maybe you have some miss matched parts. One version used a narrower needle bearing with an o-ring the other slightly wider needle bearing without an o-ring.

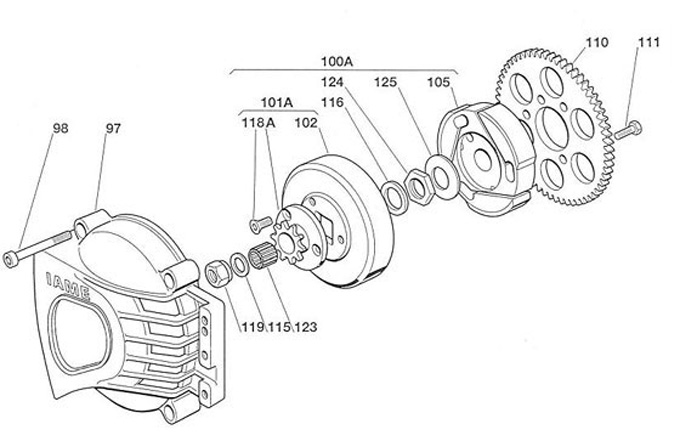

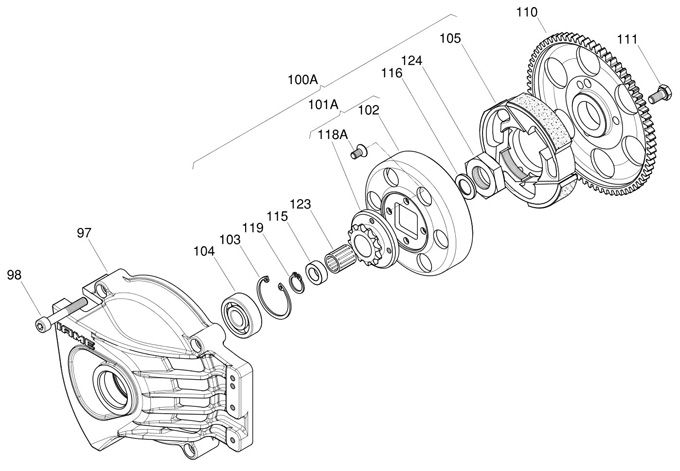

I have the original needle nose bearing the top clutch assembly is what I what I can tell because of the cover and the flywheel and are completely different for the one below

116 is beveled on the top picture should the beveled side be facing towards the clutch or the needle nose bearing? I think that could be it but I have no clue.

I have the bevel right, it may not be sitting right

Maybe throw up a pic or two for Greg to see.

I actually think I figured it out the outer nut 119 I had the the lip toward the outside in stead of the inside and have it sit the washer. I could be wrong but that look like what it is.

Nope I lied that wasn’t it

That’s how I have it set up. I was told my clutch may not be all the way in but the fly wheel is flush with the case

Thanks for photos. As a non-wrench I can’t help but the photos might help Greg or someone.

I appreciate all the suggestions, thank you.

I got it now so the big 24mm nut was some how backwards and I had to grind it down since it was a tad bigger then the original bolt.

Sorry I didn’t get back to you sooner. I suspect one or more of the washers are thicker than they are supposed to be. The nut is a specialty item with the protrusion on one side. My guess would be #115 in diagram above. Also, #116 has a beveled edge on one side that faces the engine. With the out nut tight, you should have about 1/2 millimeter of play side to side in the clutch bell.

Don’t forget to put a small bit of grease on the needle bearing during assembly and reapply every hour or so of run time.

I realized the 24 mm left hand nut was a little to big just took some of it off and it’s all good now. Thank you for the help