MEASUREMENTS AND TOLERANCES

The following tips summarize crucial points to look at, when rebuilding a crankshaft.

Download the latest version of the respective engine repair manual on www.rotax-kart.com.

Read the instructions how to rebuild a crankshaft carefully. Make yourself familiar with all safety instructions and make sure that all measurements are according to the specifications stated in

the repair manual for the best durability of our products.

Please note: The repair manual is revised every 2nd year without commitment to advise modifications.

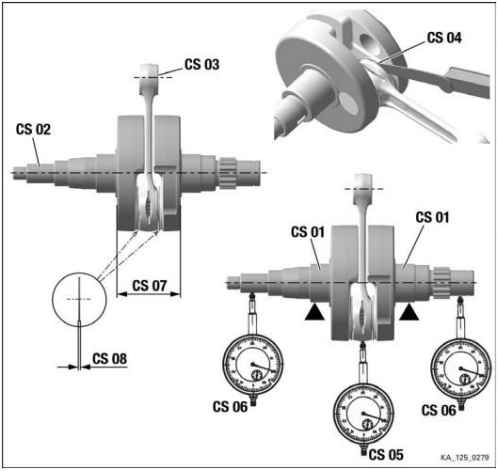

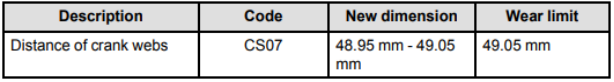

One important measurement when pressing the crankshaft together is the distance

between both crank webs (halves) specified 49,0 ± 0,05 mm (CS07) in the repair manual:

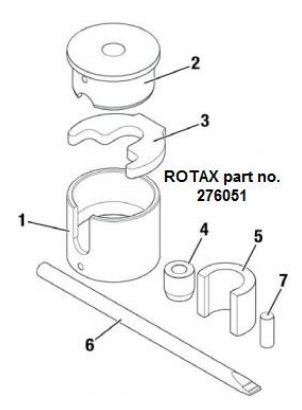

The crank web distance is a crucial factor for the durability of the crankshaft:

• Measurement CS07 bigger than specified

If the con rod axial play is bigger than specified, the con rod will travel (left and right) which could

eventually cause the con rod to break.

• Measurement CS07 smaller than specified

If the con rod axial play is smaller than specified, excessive friction will occur and create heat within the big end bearing. This may lead to a failure of the big end bearing.

MEASURES TO MEET THE SPECIFICATIONS

Using the right equipment saves time, money and effort.

• Workshop equipment:

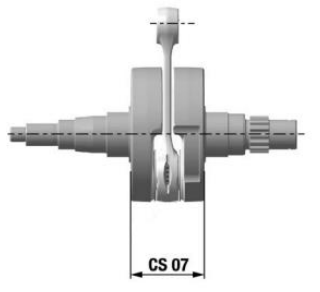

Hydraulic press with a minimum press force of 15 tons. ROTAX crankshaft repair jig part no. 276051 available at your ROTAX dealer.

• If required, use distance spacers as an aid:

Make sure to measure the length of the crank pin before installation. Depending on the measured length place an appropriate distance washer on or under the crank pin to meet the specification CS07 in the manual.

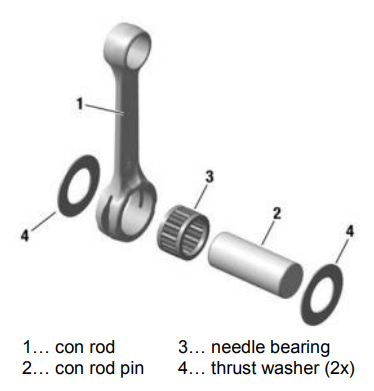

Use genuine ROTAX spare parts only! ROTAX offers either complete crankshafts (preassembled) or complete crankshaft repair kits with all parts 1-4 shown below.

ROTAX crankshaft repair kit:

To assure the appropriate radial clearance according to our specification the following parts are measured and matched together at the ROTAX factory:

• Con rod pin

• Needle bearing

• Con rod (big end)

Never mix parts of different crankshafts or crankshaft repair kits together. This may lead to severe engine damage!

NOTE: The radial clearance is a determining factor for the durability of the crankshaft.

Mixing parts together makes warranty for the engines void.

After pressing the crankshaft together, make sure to align the crank webs to meet the required values of specification CS05 and CS06 (runout tolerance).

If you have any questions or concerns, please touch base with your local authorized ROTAX service centre, they will be happy to help you.

Kind regards,

Your Rotax Team