Hello all, first post, go easy please!

My background is more ‘percussion’ engineering than precision engineering, but I found this thread after having grub screw issues on a soft axle at a recent club meeting.

My .02 worth of contribution is to ask if (1) we shouldn’t be thinking of the flex in the axle being between the loaded rear wheel and the nearest bearing, but between the loaded wheel and the furthest bearing, as the insert bearings are self aligning in their housings and the bearing nearest the loaded wheel will rotate a few degrees in the vertical axis allowing the axle to flex along say 80cm of axle. i.e. its a much longer ‘spring’ than just the 20cm of outside loaded axle.

(2) I’m sure this is blindingly obvious to everyone else but myself, but the measurement of deflection of a test axle under load is obviously made at rest, is it still relevant for an axle rotating at something like 2300rpm where the load is more dynamic?

Yeah bit of a dick but I get it. Been to engineering school, degree in mechanical engineering at an accredited school and so on a million years ago, I’m not using screen name of OldFart Karter for no reason. Oh, I can see that it could be unsafe especially, if it goes into resonance. Putting that aside, I do agree with everything you stated. I’ve looked this for a while and the only difference I could see between similar dimensioned axles is the hardness of the material. Moving from a hard axle to a soft does make a difference. There is a difference you can feel and it reflects in lap times.

Presuming that the modulus is the same and the dimensions are the same, what other physical parameter could affect the amplitude of deflection of the axle? There isn’t anything else left except for damping. I can’t disagree with you that the damping effect should be tiny but what else could it be? Although, I’ve read in old archives that the large amplitude deflection have higher damping ratios than small deflection motions. Certainly, one can hear the effects of damping by tapping a lightly held axle but the energy level is so low that it seems unreasonable that a large amplitude, low frequency motion could be altered by the inherent damping of the material.

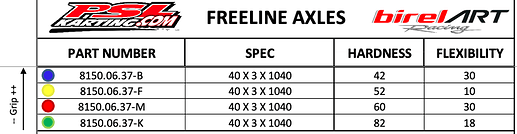

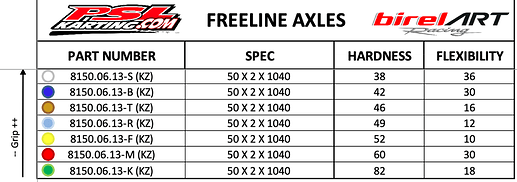

20 years ago I tested with varying wall thickness axles, and it definitely made a difference. Where I call BS is mfgs like Birel/Freeline having all these different steel axles with 2mm wall thicknesses they sell people.

Hardness (heat treat) does not change modulus. Young’s Modulus is dependent on the interatomic distance and bonding energy. And because only small fraction of the near neighbor bonds are affected by the heat treatments . So you will have a very small or no change in the magnitude of Young’s Modulus.

Per the rules (at least CIK rules) axles must be magnetic. So that limits you to “steels”. Cost considerations limit you to “normal” steels. I do not see anyone coming to the track with a Vascomax 300 Maraging Steel (270,000 psi yield!) axle, though that would be cool.

So what are we talking about? “Normal” steels. 1018 Steel. C1045 HT. 4140 HT. Etc.

1018 Modulus = 205 GPa

1045 Modulus = 200 GPa

4140 Modulus = 205 GPa

Steels have low damping. I unfortunately have to deal with this reality all the time as I work in the vertical pump industry. This is why machine tools and stationary machinery housings and frames are made from cast iron (good damping). So even one steel that has double the damping of another is still almost meaningless, because the level of damping is so low.

See Page 12 for damping of steels. Compare this with Specimen H for Grey Cast Iron on page 15.

Also, damping is primarily important when you are dealing with resonant conditions. Damping causes the accumulation of energy to be limited. Finally, the “frequency” or velocity of motion in a kart application is so slow that damping will not come into play.

I am not saying there is not something. Placebo effect? I don’t know. But no one has been able to explain what is could be. If I buy 5 different axles, test them, and they all have the same static (deflection vs load) and dynamic (natural frequency and damping out of oscillations) characteristics, are people still going to claim that they product different lap times because of some color painted on the end?

If they perform differently on the track, they have to have different physical characteristics. But I do not see how Freeline axles can have that when they are all steel, and all 2mm wall.

If I was going to buy into axle tuning, I would buy my axles from PKT. They sell 50mm 4130 axles with 1.6mm, 1.9mm and 2.5mm walls, If you take 1.9mm as your baseline, the 1.6 is 16% more flexible and the 2.5 is 31.5 % stiffer.

Thomas,

Most of the discussion here is over my head, but if I understand what you are saying they only way there will be changes in axle hardness/stiffness/call it what you want, is if the wall thickness is different? I buy that, but there are a lot of kart companies selling axles with the same thickness and claiming different hardnesses. Very confusing for the average karter.

This is all very confusing and threw my years in karting im not so sure one axle to another has made much difference. Seems like to get harder axle(stiffer) we need to increase wall thickness. I know in the OTK line 40mm axles N is a med axle and C is the harder, However the N has a 3mm wall and the C measured 2.5 or 2.6 can anyone explain that?

Bernel, (hardness) I don’t think they’re talking about that, I think they’re talking about hard to bend, easy to bend (soft). Still, I’m with you, how do they do that without changing the wall thickness? Alloys?

I would guess the alloy is possibly different. One thing to try… Take two axles of different grades and same wall thickness. Give them a tap with a screwdriver and listen to the note. (Not in the kart obviously)

There’s a lot of placebo things in Karting, but I don’t think axle choice is one of them. I’ve had karts that went from garbage to competitive in back to back sessions and the axle being the only variable.

This is one of those things that makes Karting super interesting.

![]() Or super maddening!

Or super maddening!

I have to agree with James and there is pretty consistent belief that axles make a difference both in feel and lap times.

The kart that I know pretty well is the TonyKart, the routine was: (1) low grip track, run the U or Q (soft axle), (2) Normal grip track run, the N and (3) High grip track, run the H (hard) switch when the N axle starts hopping.

All TonyKart axle have the same wall thickness the only difference I could find is the Brinell Hardness of the axles. I didn’t measure the Brinell Hardness but the hardness can easily be determined by how easily the axle is dented by the set screws.

From my observation the axle response has to be related to Brinell Hardness, which is tough to believe but it’s only parameter left standing

I’ll keep researching but if someone could do my crazy experiment, then I could stop posting and thinking about this. Maybe I could do the experiment on a kart on a stand.

I’ve always struggled to understand how any 2 axles with the same geometry could behave differently as it goes against everything I’ve learnt. Many racers at the highest levels will swear that axles, do indeed make a significant difference. It would be interesting to hear from anyone who has done any blind testing. The data in the following article would indicate that these 2 axle both display differing characteristics, even though they both have the same 2mm wall thickness.

https://issuu.com/dinhtiendung2/docs/vroom_international__december_2017_/64?ff

Hello @Thomas_Williams

Freeline has at least 3 different wall thicknesses in their products list as you can see below. Previously I had embedded just the list of axles with 50mm of diameter as an example.

Looking at the tables above, I have some questions:

-

What are the units of measurement of columns Hardness and Flexibility?

-

How Flexibility is measured?

-

Why Hardness and Flexibility are not directly proportional?

-

Why the level of grip provided by the different axles is directly proportional to Hardness and not Flexibility?

-

Why 40mm axles with different wall thicknesses have the same hardness and flexibility rates?

Any thought guys?

Just to nail something down, does anyone know if OTK manufacture their own 50mm axles, or do they buy them in from the likes of Righetti Ridolfi?

It’s hard to know in karting just how much of ‘set up’ is down to the placebo effect. Does using genuine OTK bring any benefit, or do all axles come off the same Italian production line using the same steel stock and tooling?

[I use Senzo axles due in part to their affordability, Senzo is a brand name of KKC Kart Components / UKKartStore etc]

Has anyone measured the wall thickness at the center portion of the axle? That could change the flexibility but not the hardness.

Is such mfging a thing? I suppose so, but I don’t see it in the axles I’ve looked at. They all appear to have straight wall construction, with wall thickness being the visible distinguishing metric among the 3 that I have on hand. I suspect deflection rate makes the difference, so if it were possible to induce & measure vibration in them, the respective frequencies would be unique, & also, more energy would be needed to generate equivalent amplitude in a thicker v. thinner side walled axle.

What say you?

Going through this topic again I don’t see much info on brands of axles. While it would make sense to stay with the kart manufacture, there can be a large difference in prices from the kart brands (CRG, OTK, etc) to the supplier brands (Righetti, Swift or unbranded). So as a racer on a budget should I spend more for a particular brand of axle that matches my chassis or will any axle work as long as I have a variety of stiffness for tuning?

The benefit of sticking to manufacturer’s axles is that you have a known scale of what’s soft and hard and where you are at on that.

Other axles can work of course too. But if someone tells you to run the N axle for OTK for example, you’ll have to cross reference with your aftermarket axle chart and hope that chart is accurate.

I think it’s worth mentioning as well that you may as well make the investment because axles aren’t something you need plenty of.

Id say the recommended starting axle then perhaps the next softest and next hardest axles will do.

And unless your getting into some decent biff ups they’re not something that needs replacing

It’s a real thing. I’ve told drivers I’ve changed the axle or told them what the change I’ve “made” will do and it always does what I told them it’ll do. I’ve seen new helmets give a driver 3 tenths.

The “kart gets faster” argument is difficult to quantify, the track typically gets faster throughout a day and you don’t know if the axle made the kart faster or the track is just faster.

Tell me more about this helmet please…

Any brand will fit to you as soon as you know diameter, length and flexibility you want in your new axle.

Some guys here in Brazil say that, the material (metal alloy mesh) used by OTK to produce their axles are different and better than others, therefore, you have to hear other drivers and teams where you are to get feedback about quality of the manufacturer you are going to use.