Thanks for the info even though i am coming to it late. I am running aluminium axles with a view that they are more likely to give me better chracteristics for racing on dirt.

I have 2 with different wall thicknesses. Am i fooling myself to think this will help create more flex in my whole system (Ithink of flex but imagine better modulus)

Thanks from New Zealand

They are on VIMEO now

I would think Aluminium would not have the same Spring effect as Steel does? In other words it does not return to original state after a force is applied as well as Steel does. I guess it would depend on how smooth the track was and extra caution for avoidance of contact. I believe the rules for paved sprint racing require a steel tubular axle above kid kart class.

As I start to plan my 2021 4 stroke season season I have two different karts (OTK and Swiss Hutless) I am trying to get to handle similar. The SH has a 30/32mm chassis and stiff axle and the OTK is the 30mm with a N which I believe is a medium axle.

I love the nimbleness and rotation of the OTK, wondering if it could be as easy as switching the SH to a softer axle to get it to feel similar to the OTK?

It might be that easy. But keep in mind you’re not comparing apples to apples, you’re comparing… cheese to pasta in this case.

The SH is different design, tubing diameter, and frame material than the OTK, so it might not be as straightforward as tossing the same axle in both. The SH will likely require some further adjustment.

Will the OTK axle work in the SH so that you could test it first and see? I know a few guys who have yanked all their stock components off their karts and replaced it all with OTK stuff before.

I switched all my stuff to the swift otk replicas. Purely for price reasons to maximize available axles for testing and learning. They worked great for me

Pretty sure PKT produces 2.0, 2.5 and 3.0 axles for 40mm.

Last year I only ran an OTK type N, I never had different length rear hubs to see if that would make a difference to “stiffness”.

For this season I have bought an OTK type Q and OTK type H to see what works for me.

I will do a test of these all back to back and report back on this post once I have engine and kart set up and track is open again!

In what condition? And is this for lo206? Which chassis?

Like I said, the N should work in 95% of conditions. Extreme grip or lack of grip will necessitate an axle change.

This is for any of the OTK karts.

I was going to create a separate discussion but I think the question I have is fully related to the flexibility of axles, so here I go.

Additionally of thinking about the flexibility of the axle to potentialize or reduce the jacking effect, could we think about it to reduce or neutralize the negative camber it causes to the rear wheels?

I am creating a train of thought based on the following statements:

- the greater the flexibility of the rear axle, the more negative camber it causes to the rear wheels mainly for heavy classes.

- in a corner, the jacking effect helps to reduce or neutralize the negative camber in the outer rear wheel.

- regardless of the setup we have, the tighter the corner the higher the inner rear wheel goes

So, is it right to say that, we will be benefited from more-flexible axles in tight corners as it will neutralize the camber generated by it when we are in the middle of the corner with the kart lifted up?

In the opposite way, long corners will be benefited from less-flexible axles as we turn less the steering wheel and we lift less the inner rear wheel?

I am not sure I was clear enough, but I can try to make some drawings to improve the explanation of my question if needed.

I think you are approaching it from the wrong direction. Try to think of it terms of deflection like a spring. At rest there is little or no deflection, but when a force is applied (weight transfer) then it will deflect. Unless the axle is a wet noodle, there is not likely to be any negative camber unless under a very high load caused by an extremely gripped up track. A soft axle will lift slower and stay up longer than a hard/stiff axle, because it does not take as much force to deflect it. On a green track (little grip), wet conditions or a lower CG Driver this can be a good thing as you will be able to keep the outside rear loaded longer. However, when the grip comes up, you can end up overworking the outside rear and traction will actually fall off resulting in a hop.

I am a tall driver with a good portion of weight at chest to shoulder level. I found it very difficult to drive on a OTK N axle (except in the rain), because I transfer so much weight in cornering. After switching to the H, it got a lot smoother. It may also differ between chassis makes. OTK tends to have a very flexible waist whereas CRG does not (so I’ve heard). For others, going the opposite direction may give the desired effect.

@tjkoyen may be able to explain this better.

- All steel alloys have a similar Young’s Modulus (stiffness for a given geometry)

- Heat treatment does not affect YM/stiffness much.

- Changing alloy will not change the YM/stiffness much, from one steel to another. Compare cheap 1018 steel to exotic 300M aircraft steel. Same Modulus +/- 2%

- Heat treatment does affect the point at which something bends (fails due to plastic deformation…ie your axle is now junk). That just means you can crash harder before the axle bends. But until you bend it, it does not act any different than a lower strength axle you can not hit as hard.

I definitely buy into stiffer and softer axles affecting kart handling. They do. But there is no way I am wasting time changing out one steel axle with 2mm wall for another steel axle with 2mm wall. They are the same. I do not care what marks the mfg puts on the axle. If I want to lift the tire more easily and rotate the kart more on entry, at the expense of braking and entry stability, I am putting in a 2.5mm wall axle. It IS stiffer. If I want more stability under braking, but less active inside tire lift, I am going with a 1.6mm wall axle. It IS softer.

If someone had a variety of axles this would be easy enough to test. Hang a weight midway between the bearings and measure the deflection.

With a 50mm axle I never thought much about it.

Admittedly, I don’t know why the hardness/alloy of the axle affects kart handling but it does. As to your question: Will all 50mm steel axles with identical wall thickness will statically deflection the same within their elastic range? The answer is yes. If not then we might as well throw out all of the engineering books, calculations, theories, airplanes would fall out of the sky and bridges would collapse (might be a gross exaggeration). Here’s a link to the explanation: Exploring the Stress / Strain Curve for Mild Steel - The Chicago Curve

What is known is:

-- Kart axles are not statically loaded but are dynamically loaded as they are being rotated under a deflection load.

I can think of two phenomena that could affect the deflection of the axle, there might be more. Inherent damping of the material and a change in Young’s Modulus as it nears the deformation point. Young’s Modulus defines how much metal deflects for a given load within the elastic range of the material. Young’s Modulus is the same for all steels regardless of hardness or alloy.

Someone in Italy knows. I found an obscure article (from Italy) when racing bike were made of steel comparing soft steel bikes with hard steel bikes and the differences in ride characteristics.

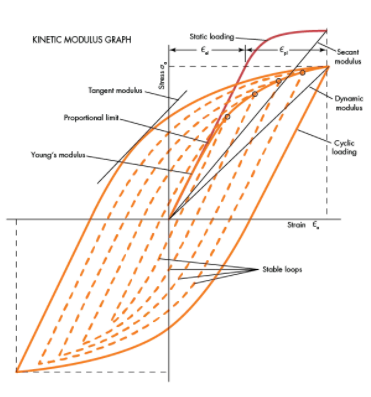

Here’s a real interesting link, I just found, StackPath on study that shows that the modulus elasticity changes when the load is statically, dynamically or cyclically applied. The article claims that the kinetic/dynamic modulus of elasticity changes as a function of yield strength (~hardness), which could explain why axles of different hardness exhibit different stiffness under load.

I understand the young’s modulus is the same for all steels, but there’s something I can’t explain, 2 karts, one Italian, the other American. I observed them from above, going into a corner, side-by-side, and was surprised to see that the Italian kart just sat down as they broke for the corner, while the other kart was bouncing and twitching. I understand the Italian kart is made from 1018 mild steel, seamless, drawn over mandrel. The American kart was made from 4130 chrome Molly. I was amazed at the difference in handling characteristics. Young’s modulus notwithstanding, the 2 frames were definitely different.

Yes the article could explain the handling differences in the two chassis. What the article implies is the traditional doesn’t-change Young’s Modulus only applies to static loads and not dynamic or cyclic loads. If the load is dynamic or cyclic “Young’s Modulus” changes also due to tensile strength. Hardness is an indicator of tensile strength.

I repost here one of my previous comments from last year on this subject:

The preceding article explains the concepts very clearly, but makes one extremely faulty assumption, ie that the young s modulus of steel is always 200, regardless of the chemical composition or the heat treatment that said steel underwent, or even its thickness. A very quick research online produces several scientific papers, that clearly show that it may vary between 180 and 210.

This paper shows that some specialty steels reach even 245

https://www.tandfonline.com/doi/abs/10.1179/1879139514Y.0000000127?journalCode=ycmq20 9

So varying quality of steel certainly will affect the amount by which an axle will deform under the same force, ie an axle may be stiffer or softer even without varying its dimensions.

Therefore, changing axles certainly will be one of the factors that influences the behavior of a chassis,

Given the time and effort required to do that, it is clear these days that the most successful kart manufacturers are trying to broaden the performance envelope of the chassis as much as possible. The most successful manufacturers are trying to provide a product that will perform extremely well with a base setup that covers a very wide range of tracks, temperature and tyre characteristics. This will leave just a few small adjustments needed to reach the optimal performance. Tipically axles will be changed very infrequently.

Nobody’s saying anything about different size axles!! **Either diameter or wall thickness.

You are overlooking one important thing…tires,it makes a huge different when you have to run white Vega’s and a week later red MG’s…same track.

Do you think you can run the same axle?