Thanks. The best analogy for what I’m doing is creating an LED motor while everyone else is trying to improve the incandescent motors. It seems crazy until it works.

Don’t forget me when you’re a billionaire

Would it be possible to use super capacitors for a gokart ? With energy recovery ? Or maybe an hybrid supercapacitors and LiPo battery ?

https://www.everythingpe.com/products/supercapacitors/skeleton-technologies/1049-278-skelcap-sci3400

Using that principle NAWA RACER Electric Motorcycle with NAWA Ultra Fast Carbon Battery - EICMA 2021. - YouTube

Supercapacitors? Sure, but they don’t hold much energy themselves. They are however very useful for buffering batteries for quick bursts either way. Some new battery designs include them inside the battery cell for this reason.

Something else I should mention is that energy recovery adds more heat into your motor. Since permanent magnets simply stop being magnets when overheated, this means you have to remove this extra heat before damage occurs. In the end most projects I’ve seen simply turn off regen for racing purposes as it does not regain enough energy to make up for the extra cooling required in a pure EV format (better for hybrid designs).

I’d like to give a shout out to Elias for being a sounding board for my nooby CNC part designs.

I also finally received the SSE 15t sprocket so I could properly measure and create it in CAD for the shaft design. Vantage Karting got the part out quickly, but apparently UPS decided to route it via Edmondton Canada or something on the way to Edmond, OK.

Little did you know, I’m just parting out all your questions to even more knowledgeable people.

Nah JK, mostly.

The only part that I think is within my ability to make is the motor mounts, but im gonna have to do some digging to find stock big enough.

Im just happy to play some part in this really cool project.

Have you gotten any quotes yet on parts? I’d guess 2-3k for everything

Hey no problem, the more eyes the better. I’ve got some “instant” quotes from several places, with the best domestic quotes at about $350 per case side, or $65 ea if I ordered 100 :-).

I don’t have anything yet for the rotor as I was still tweaking that for the gear width. I’ll see today.

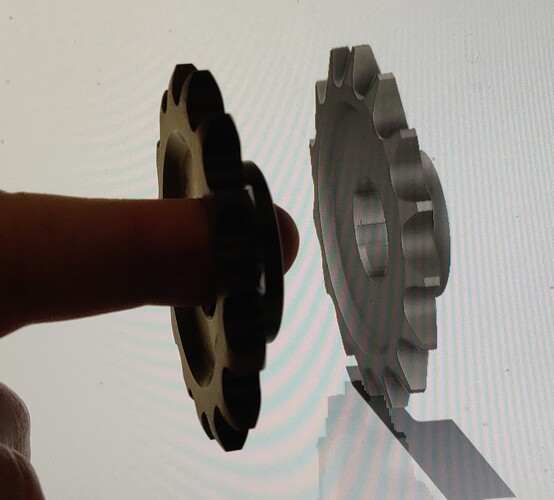

The SSE 428 sprocket profile is interesting in that it is quite a bit different than the Honda CR80 428 sprockets I have. Here the SSE is on the left and the Honda on the right.

Cheaper than I thought! That is weird. Do they use the same chain?

Yes, both #428. I would think the SSE chains would wear quicker due to less meat on each link roller to take the power.

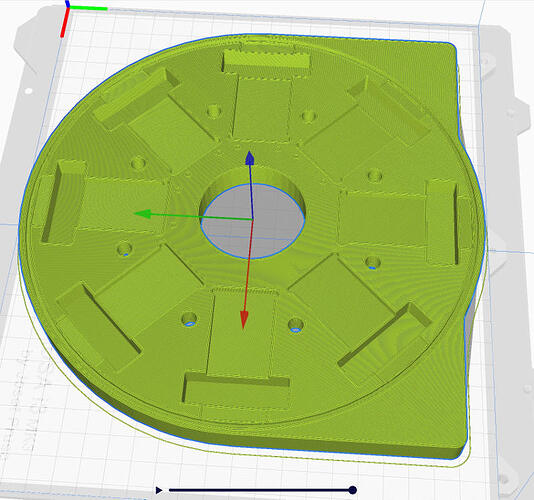

Proof of concept done! Had a couple errors (drill didn’t go deep enough, went where it wasn’t supposed to go) but I’m happy

More ideas are welcome, and I can give the full thing a shot, but it may take a while, and if anything needs to be tapped than that may be a problem for me

That looks awesome, well done. Mini motor 1.

I’ve sent the files for the sides and rotor to a local 3D printer to verify assembly and hole spacing for timing before committing to CNC. I did decide to mouse ear as you called it, the bottom corners. More to come.

I think it’s also called crescent moons. I think that’s the best idea. Stress will be down, machining cost will be down, and Fitment will be easier

Thank you! I’m happy with how it came out. Just have to countersink the holes and it’s done. I could give the full size thing a shot, but I’ll have to find stock big enough. It would probably be about $150 for 2 8x8x1 stock

If you want to try this I could drop ship you two 8x9x0.75" pieces (0.125" cutting tolerance). Send me your address in email.

I’m gonna give it a shot on a large wax block, and if that works than heck yeah

Physical motor is coming along nicely. I stuffed the plastic case halves with all 8 poles without any issue, and the rotor spins easily enough (given it warps a little being plastic). The tape shown is a simple cover to keep anything from being magnetically attracted to the magnets. The aluminum should be delivered to Elias tomorrow so he can get to work on CNCing them into nice solid parts. The coil bobbins are being printed, and then I can get wrapping the other 14 coils (at about an hour each). I hope to have the frame mounts by the end of the week - but as of this morning those still show as back-ordered… Yeah.

Up next is electronics. I’ve been studying up on KiCAD to create a printed circuit board that can be stuffed with all the required components. This first one will be a mix of surface mount and through hole, since you have to use what you can get currently. Anything production will be surface mount for best resistance to vibration. Lots to learn with this program, but I hope to have a rough board layout by the end of the week.

Surface mount and lots of potting! KiCAD is fun.

Let me know if you need help with circuit board. If you have the schematics done, I can probably lay the board out the same day in Altium.

Interesting video for anyone looking at electric motors and battery packs. I really like Lucid’s electrical connection and cooling arrangement compared to Tesla’s.

I may take you up on that, thanks for the offer. I’ve been coming up to speed on PCB layouts and parts from what I learned in the 80s and early 90s.