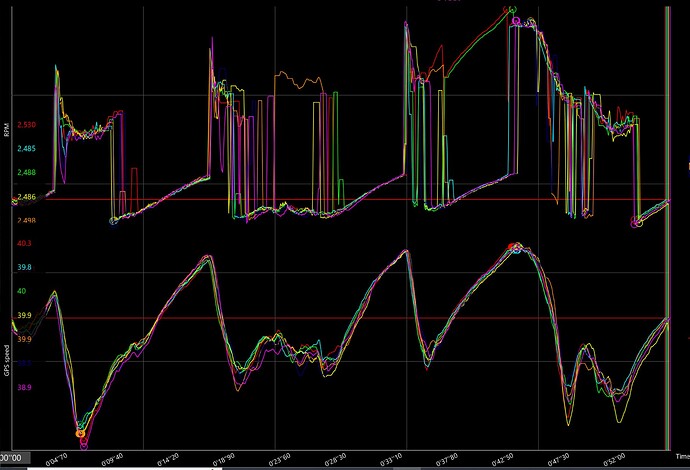

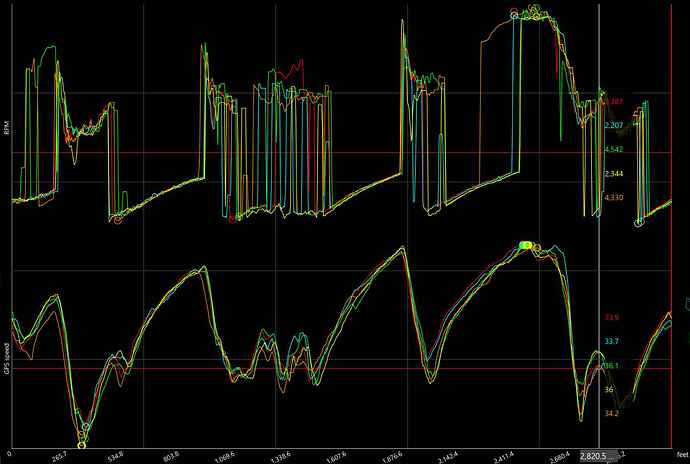

I am seeing a false low RPM value in my trace data in ADA from an Alfano 6 measuring a LO206 engine when under load and seems to be worse at higher RPMs. It seems to be missing every other ignition and measuring half the actual RPM value. When I get on the brakes the RPM spikes back up to the actual value. See first two images for example data with multiple laps from multiple runs.

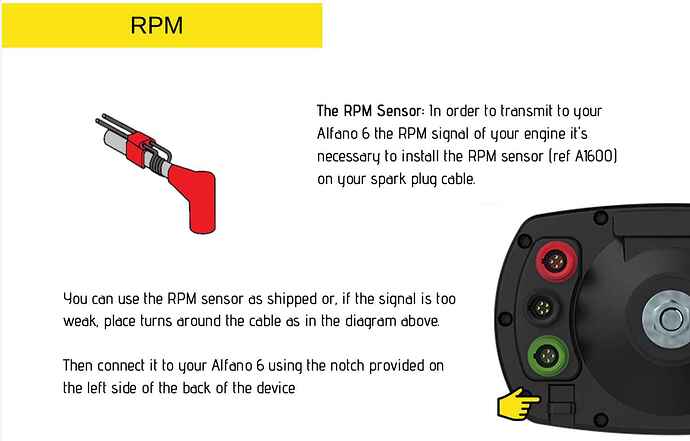

I’m believe I have the RPM sensor wire installed correctly per the instructions. I did not trim the excess wire as it did not state to do so in the instructions (in hind site this may have been the issue), but just zip tied it behind the steering wheel (see Figure 4).

I did not think the extra loops should cause too much issue as it is kind of randomly arranged, so I did not think there would be enough inductive coupling to mess with the signal coming from the spark plug, but this is the only thing I can think of at the moment.

I have installed a ferrite core on the wire but haven’t been able to test again due to there being snow on the ground in my area (need high RPM/load to validate), so I won’t know if that made a difference for another couple months. I don’t really have any other electronics on the kart currently so I’m not sure where the noise would be coming from.

Has anyone else seen this issue with their Alfano RPM data? Or even with their MyChron data?

Is 4-turns on the spark plug wire enough for most people? Can I just add even more turns to the section around the spark plug wire? Keep adding turns there until the issue resolves?

Thanks for any feedback!

Figure 1: Alfano_ADA_Data_RPM_Noise

Figure 2: Alfano_ADA_Data_RPM_Noise2

Figure 3: RPM sensor wire installation on spark plug wire

Figure 4: Extra RPM sensor wire zip tied behind steering wheel

Figure 5: Alfano RPM sensor installation instructions