Sounds like a mfg repeatability issue…

No they are just made from different alloys of steel i’m sure… Even heard of some chassis’ using heat treated material or being heat treated after welding. As far as karts go, different steels make a drastic difference in how they handle and feel.

Funny.

Four different types of heat treatment is what I was told from the factory. But I’m sure their engineers have no idea what they are talking about.

TJ, four “types” of heat treatment?

Normalizing

Soaking at Critical Temperature

Quencihng

Tempering

Those are different phases of heat treatment for steels, but they are all parts of the same process. There is also nitriding and/or carburizing for low carbon alloy steels…this is the sort of thing they do to make bearing races and rolling elements hard…

Sorry…I don’t buy that they are doing “4 types of heat treatment” on a kart chassis. I specify HT for rotating machinery components, and it is expensive. Kart chassis are not expensive.

I agree with that assessment which was why I was asking Charles for confirmation or clarification. I just chose to not be quite as direct. ![]()

I know our chassis has exceeded yield a few times. ![]() Catching air or hopping karts tends to do that.

Catching air or hopping karts tends to do that. ![]()

Yes. Max-effort cornering/curb hopping induces plastic strain. Not much, not everywhere, but enough to measure and enough to really cut down fatigue lives. Highest stress zone is exactly where you think it is, not helped by the thickness transition at the weld.

Soak, water quench, temper to RC30 costs double digit dollars per kart frame with a cycle time of about two hours.

TonyKarts are not heat treated at all.

There is a major brand that is heat treated. It’s not through-hardened.

When investigating manufacturing chassis with the big frame makers, I was offered 3 tubing treatments with the karting descriptor in brackets:

GBK = annealed (soft)

NBK = normalized (medium)

BK+S = cold drawn and stress relieved (hard)

I believe there’s also BKW (lightly cold worked) and BK (cold finished as drawn) but they weren’t offered.

They didn’t want to use different sizes, available but not preferred.

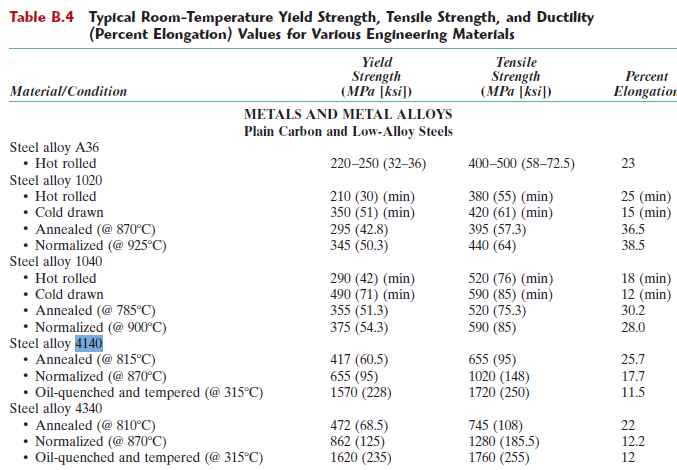

Heat treatment doesn’t effect the flex, it does effect the Yield Point.

So I’m going to posit a hypothesis (additional to my own post i refound below). A kart is always under some load, through its own weight and the quite substantial (proportionally) weight of its driver (or the drivers lead in @tjkoyen’s case ![]() ). In part of cornering, some part of the kart is entering the plastic region, maybe only slightly, and the load of the weight of the driver is bending it back again (plus the going left and right as we do on most kart tracks). This back and forth hardens the frame over time and also deforms part of it. It’d be interesting to just go round left hand corners for a race length and see if the frame deformed (bent) in that direction. It’d have to be a typical kart surface, not a dirt oval, that relies on the kart keeping a wheel up to be fast.

). In part of cornering, some part of the kart is entering the plastic region, maybe only slightly, and the load of the weight of the driver is bending it back again (plus the going left and right as we do on most kart tracks). This back and forth hardens the frame over time and also deforms part of it. It’d be interesting to just go round left hand corners for a race length and see if the frame deformed (bent) in that direction. It’d have to be a typical kart surface, not a dirt oval, that relies on the kart keeping a wheel up to be fast.

So by using hardened tubing, designers are moving the yield point to have the kart only just go over it for the given tire engine combo.

Apparently I’ve come to this conclusion before:

I’m impressed with your consistent thought process on how karts work! I change mine daily.

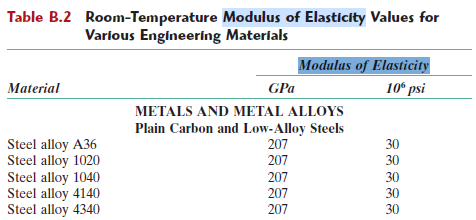

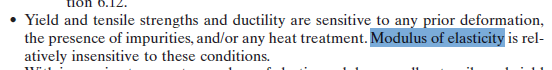

I don’t believe this to be true. Springback/flex (whatever you want to call it) are proportional to yield strength. Which is a by product of different heat treatments. Been awhile since I was in my college material science book, so I’m only 80% positive on that. Someone I’m sure will fact check me.

Found my PDF book. Self fact checking…

Or not… Modulus of Elasticity seems relatively unaffected by heat treatments or chemical composition in steels. So this leads to rabbit hole #2. What then is affecting axle stiffness? ![]() I think we also beat that to death in another thread.

I think we also beat that to death in another thread.

That’s a danger topic lol.

Not sure if your question got answered but I think Parolin does.

Anyone remember the old Kart Mini chassis (Brazil) and their range of axles? They had a crazy range of axles based on different heat treatments, seemingly localized to various positions on the axle (multiple areas with different coloration). That was a next level head scratcher…

Oh, man. Those were hot in SIRA when I first started street racing. Burgess and a few others ran them.

I never noticed that, but the Kart Mini guys really ripped in Rotax back in the day. Gabby Chavez was one of their drivers along with a few other really good South Americans.

From what I heard the founder of Kart Mini knows a lot about karts, don’t know if he’s still alive. There are some saying they want to start to sell in Europe in the future

Wasn’t the founder of the Kart Mini Emerson Fittipaldi and his brother Wilson.

Although I think they sold it on a long time ago.

Yes. Emerson and Wilson Fittipaldi know a LOT about racecars. Remember, they built and raced their own machinery long before Emmo got to F1. Look up their twin-engined Beetle that they used to outqualify the Porsches at a sportscar race. It would not surprise me at all if they’d found a really skilled metallurgist and worked with them for decades including on their kart project.

You could absolutely induction-harden an axle under and next to the bearing carriers so that it would be a lot harder to damage at the stress concentrations yet still be able to yield away from there.