Milestone! It works on the bench…

If you watch the video above closely, you can see (well hear) that the trigger is messed up. Firing multiple times for a single pass. Sometimes that happens when the two poles of the magnet pass the hall sensor. But it should be fine with this setup. Anyway got that resolved by reloading the base tune I made.

Not sure what happened, but it seems stable now. Since the 206 is in the garage, I’ll make a run at that first.

Somehow I don’t think this will pass tech.

Waiting outside the hardware store for it to open and see what I can make an intake manifold from.

I wonder if the WF intake and boot would work for this. Not sure on the sizing. Definitely bolt on though.

Yeah the elbow probably from a WF might work. For now I’m just working with whatever I have and haven’t gone too deep into the 206/animal specific setup.

Yesterday made up this adapter.

Worked on cleaning the wires up a little.

Sounds like a challenging and fun project that could provide lot of self satisfaction, but I am skeptical you are going to get OEM and sanctioning bodies on board. Without that, you are going nowhere as far as a “product” is concerned. If you really want to make this happen, the first thing you should do is take someone like Tom Kutscher out to lunch.

For example, lets talk about crank timing. Every engine with properly applied EFI/ECU systems has a crank position trigger wheel with mating Hall Effect sensor to provide very precise timing. With a compact purpose built racing motor, this would need to be built into the motor design by the OEM, and the sensor mounting would need be designed into the case casting. Bolting on shade tree engineered trigger wheels and mounting carriers for sensors is not going to fly if you want a credible product.

One more example - what about performance control? Open source…great! Right up until a smart guy uploads a new hex file to the ECU to get more performance at the expense of reliability. That means the ECU firmware needs to be controlled. This has been a common issue in auto racing for a while. I recall back in the late 90s working on a FF2000 pro car. Pectel ECUs that were controlled. You could not adjust anything as the sanctioning body held the passwords. Are karting sanctioning bodies going to want to mess with this? Can you implement controls on the Speeduino open source platform? Are you prepared to re-write the firmware to apply encryption and password controls.

Finally there is cost. If you add up all the parts for a professionally configured product, I bet you are talking 2-3x the cost of a “blueprinted” carb.

These are just a few potential roadblocks to really developing a “product” that could be used in karting.

Again…I think you need hitters in the industry to be on board that this project. It needs to fulfill a need they see. Again…take someone to lunch and see if this meets a need beyond your desire to work on cool project.

I’d love to see the gains that can be achieved with an EFI system on a 2 stroke, especially if you can adjust the ignition timing based on rpm.

Those are all good points, to an extent go without saying. But here’s where I’m at on a few things… If there were no roadblocks this would not be interesting to me.

That’s OK, although buy in from sanctioning bodies is nice I don’t nessacarily need their buy-in. The system has scope beyond karting, including my own rental kart fleet (Honestly makes it worth it alone) and a pretty massive mini-bike market with the Honda Grom and it’s clones.

But yes, I’ve had some exploratory conversations with trusted partners in karting about this and some other concepts. Naturally, a kludged up system in my garage is not what a final product will look like ![]()

This is more about me getting my hands dirty with a system and sharing my experience along the way. Telling the story, warts and all. This is something that will take a team to build a final result.

If I’m understanding correctly, we have the same challenge with “analog” timing? In the past there have been various methods of implementing “basic” timing limits, including spec timing plates for the stator for example. Basic timing for an EFI system can be controlled in the same way, save for going into the weeds with verifying a trigger wheel’s nuances.

That’s partly why I’m doing this… I want to test these assumptions we make…I’d like to see for myself what does it in fact cost, what are the benefits and do they make it worthwhile against the backdrop of real-world racing. Can it add value across to the spectrum of racers… if how, how?

A lot has changed in even the last five years on costs and quality of the components of these systems. At the end of the day, that blueprinted carb still needs to be tuned for conditions in most high power classes. Looking across the spectrum of racers (Vs top tier) it’s apparent that most would really rather not deal with any of that.

It sounds like the devices you worked with may have been flashable via their data port or another method? Speedunio is modular, we can take or leave what aspects serve the goals our own project. Including programmability. I should make the point that Speedunio is the starting point… It may be the winner, it may not. We could go another direction if needed. First it needs to be determined if EFI can potentially deliver value, it’s certainly a good platform to evaluate that much.

Programmability can be optional. We can make custom circuitry that does not have a path to support reprogramming flash if needed. It would require breaking the physical case and manually flashing the memory on the board… which is pretty trivial to detect. That said, the easiest way to combat ECU trickery is what we did with Stock Honda CDIs… swap them on the grid at random. Encryption and CRC checking etc these days is pretty trivial to implement.

The downside to this approach of course is that we’re painted into a corner if we have to make revisions to the units in the field.

Fuel injection on two strokes is difficult. But for RPM/ignition maps you can use programmable CDIs (Ignition boxes). With so many spec classes these days (Programmable) CDIs are few and far between, but you’ll sometimes see a programmable CID in the open classes and/or attached to a modified CR125 or CR80.

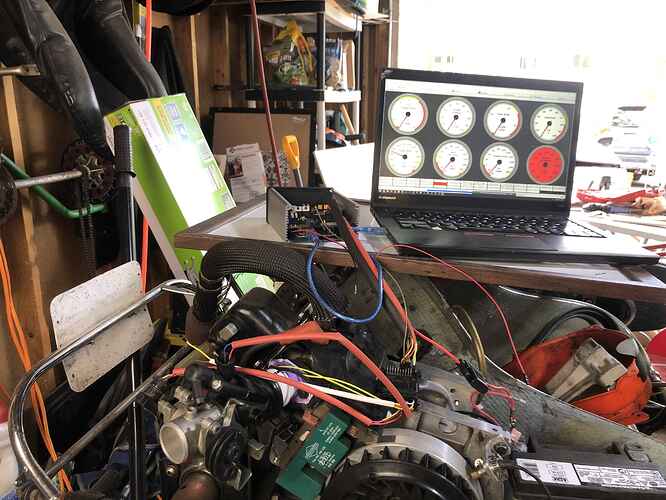

First fire up yesterday on a 206. Not without issues, mostly from rushing to try it out before picking kids up for school. Fuel tables need some adjustments but it starts easy and responds well to throttle.

Forgot how much these things vibrate on the stand ![]()

I’m going to push back some on your mostly reasonable post.

When I did some floorplanning for the same general idea of an EFI 212cc predator, the general realization is that your concern over maps can pretty easily be suppressed: At boot (initial power on) the ECU will usually load up a map from Flash / non-volatile memory into volatile RAM. This is necessary just to start the engine, let alone run it.

Once running, the RAM map can be altered and fiddled with, without much of any consequence so long as it’s not a bad map. Once everyone is on the grid, a ‘race map’ can be uploaded into each ECU’s RAM, along with a checksum (a kind of fingerprint for the map). This could either be done from a near-field radio, or through a hardwire port (what I think would be better). If the engine gets power-cycled at all, that map is lost and along with it, the fingerprint. Verification can be had upon returning from the track as a part of techning.

Now as to acceptance, there are two ways and you only touched one of them: You can buy your way in, or ‘accept’ your way in.

A class can generally be formed when enough racers of that class show up to an event and it gets recognized. If OP built 6 kits of identical nature, and 6 racers show up to a smaller club, they’ll likely get a class and a race. From there, it’s about selling the value of that kit and organically growing the motor’s class. [Plus one would need to write a ruleset for the class similar to the TaG book]

In regards to cost, it really is a function of where the end product winds up. If I can buy a WF kit for $1k, and an X30 for $3.5k, and this kit gets me X30 power with WF reliability for $2.25k, well damn son sign me up. If this can be made with an electric start, even better.

I should probably add that I don’t expect the system to add power to existing engines, at least not without engine modifications… which makes it a whole new ballgame anyway.

“206i” on methanol + Nitrous could be interesting

Maybe not practical, but fun until it comes apart.

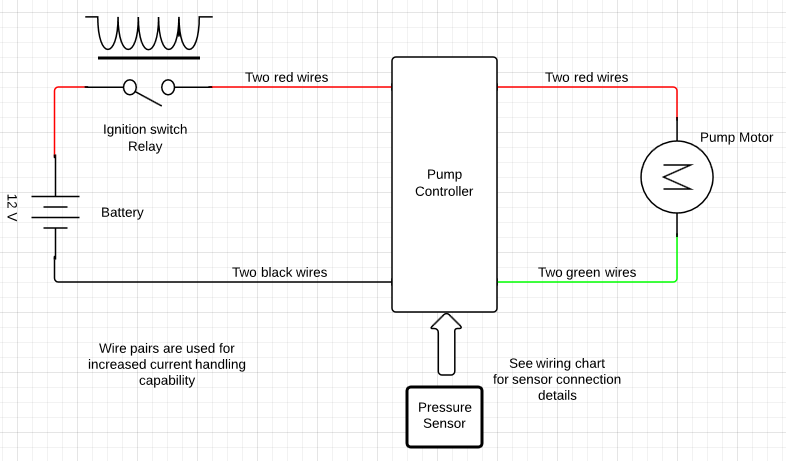

Fuel Pressure Control & Power Management

Anyway, main update for today is that the parts for the returnless fuel pressure regulation system have arrived. One of the biggest issues of the EFI system is the power drawn by even the smallest fuel pumps. It’s as much as 2A.

Every EFI small engine system I’ve seen is a lossy one where the pump is always on and it requires a return line to the tank. Of course it also requires a bigger generator too, drawing power from the engine.

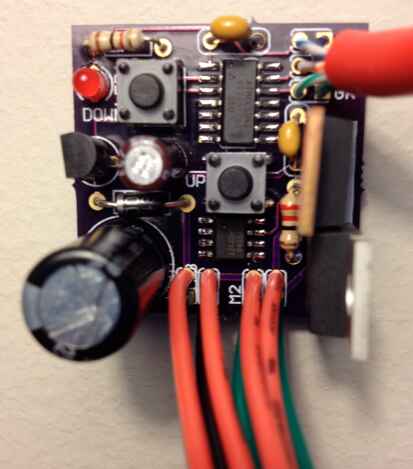

This PWM setup will electronically control the fuel pressure by modulating the pump.

System overview:

Controller Board:

Advantages:

Reduced power consumption

Single fuel line from the tank

Better fuel pressure control (The standard deviation for the mechanical regulator is about 2.75 PSI, compared with 1.68 PSI for the electronic regulator.)

Disadvantages:

Additional cost

Bulkier than I would like.

More wiring.

Potential source of failure… although this is fairly remote all things considered.

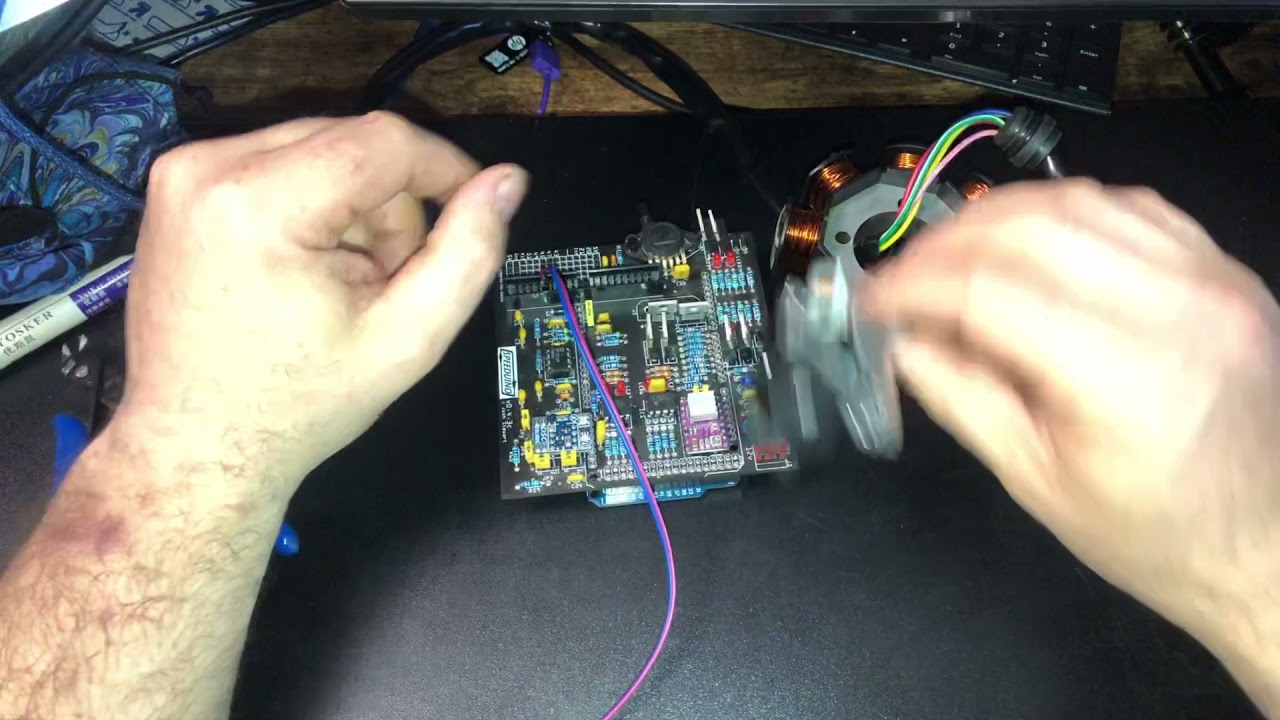

Originally I went with a Bosch four pin fuel pressure sensor, but it’s excessively bulky, the fuel connection is comparatively huge and it and has a temp sensor included which we don’t need…

So, I’m going to use an AEM “Style” 1/8" NPT 100PSI transducer instead.

Which conveniently goes into this:

There are Optical triggers available as well and they are more compact than a Hall setup. That could eliminate magnetic interference from the stator triggering the Hall sensor accidentally.

The thought is to run VR sensor with a 12-3 trigger…

Same setup as the Honda Grom so it can be used with their EFI models 2015-onwards as a standalone ECU. It would cover the CBR250 and others that use that same Keihin ECU as well.