What’s the recommended piston to head clearance for these “big block” engines?

If it makes a difference we’re running ARC billet rods. I have 0.040” (1.016mm) as the spec now which seems a bit tight for such a big slug.

Background: Going through the VC460 engines on our rental fleet and noticed we have some witness marks on the piston crown. Admittedly the reason we’re taking them apart is due to smoked rod bearing shells… so it could be just that. I figure since were going though them it would be wise to send them out with sufficient head/pistonclearance. Not looking to set to kill.

Here’s the specs I have for reference for our VC460 with billet ARC 4.510” rods. They may or may not not apply to other engines. Open to feedback on these in a non max performance setting.

Big end bearing (ARC 4.510” Rod): Oil clearance 0.002” - 0.004", torque 120 in/lb, 144 in/lb then 180 in/lb

Crank web diameter: 1.4160" +/- .0005"

Ring gaps

Top (Chrome): 0.016”

Middle (Black): 0.018”

Oil scraper rings: 0.015”

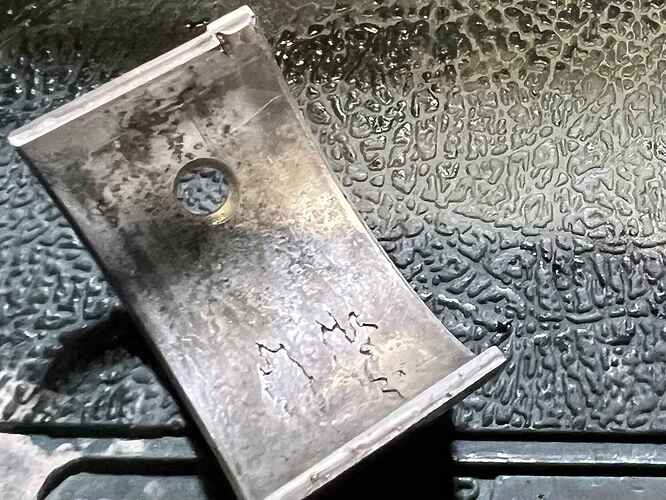

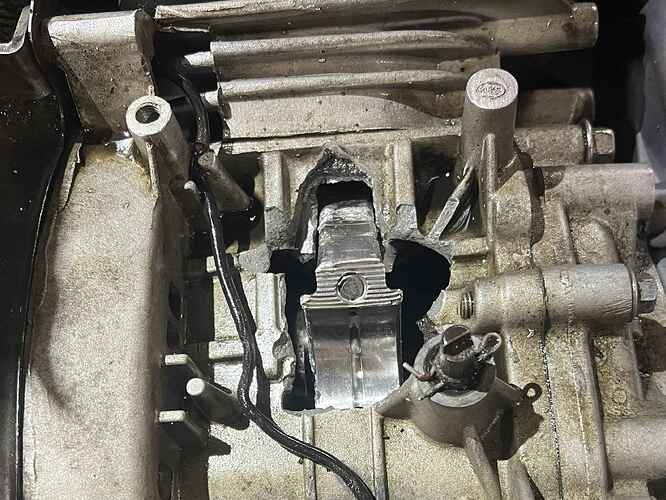

Carnage Pics for entertainment.

Bottom one reminds me of when my x30 blew. What happened there?

Rod bearing let go. Clearance opened up and rod knocked around until kaboom. We have four like that

1 Like

My clearance was as tight as I could make it for squish but we had a 49cc rule for combustion chamber and had to run a 4.410 Rod length.

Our biggest failure point was rod bolt failure or Piston failure

1 Like

Can you remember where you would end up for head clearance? We try to keep ours around 4200 RPM on track at the peak and maybe 5200 if it’s super slick and the wheel spin is severe.

Circling back as we’re almost done refreshing these. They all had 0.010 popup and 0.027 or 0.020 MLS head gaskets.

In short they were assembled (not by me/us) with the longer rod but the pistons were not machined to match. With head to piston clearance between 0.010 and 0.017 and questionable rod bearings it’s an absolute miracle more of them did not blow up. As far as I can tell the absolute min is 0.020, but that’s for a racing application with much more frequent rebuild periods.

It also explains why compression was anything between 225 and 250 PSI

They now have 0.045 head gaskets, pump around 160/170 psi compression and idle so much better it’s not even funny.

Found a bunch of cracked pistons of course. Finding replacement rings and pistons (92mm wide ring type) was a bit of a challenge. I’m fact I don’t have the replacements on hand so I’m hoping pin to crown distance is the same.

I think this is our last season with these engines.

1 Like