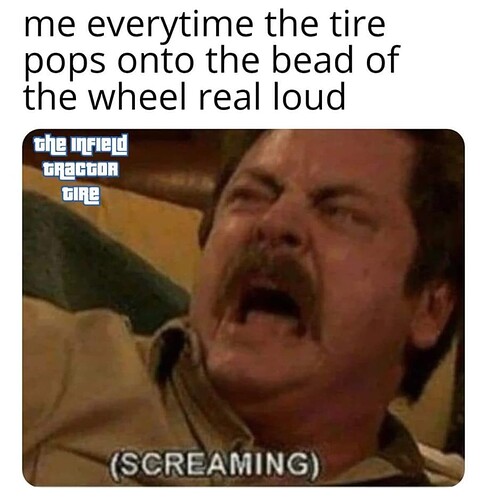

Can confirm the “even up the bead” method does work when you have run out of other options.

Only 80? I’ve shoved close to 150 in tires before. Tire band, clip on chuck, hide.

Scary as shit, don’t recommend… Us 4 Cycle guys do stupid stuff, tho.

This is how that guy almost lost a finger. Eventually the wheel goes boom.

I just got a Turbo Tire Changer. Windex does a good job with slicking the beads & side walls to make things go that much smoother.

sorry not sure I follow the rain tire discussion, are we talking mounting rain tires on regular rims instead of rain-specific rims?

These are standard Douglas rims but 6.0 for rears instead of 7.0. The rears went on easier but the front rains, geez. I had the same problem as Andy the tire would walk up on one side to the bead but side opposite wouldn’t budge.

That’s the point of no valve core, clip on chuck, and tire band. You can do it from across the room.

As a newbie, I struggled to get the beads to seat on my wheels. I found success doing just as you suggest. I bought a tire band and a clip on chuck but, I also put a ball valve on my compressor so I could hit the tire with a blast of air. I have about 20’ of hose so I can set the tire/wheel at a safe distance from the compressor where I control the airflow. It works really well.

I use windex and the clip-on chuck for all tires. I can turn the pressure dial up on the compressor until it pops then disconnect the air line and left the pressure out.

I’m imagining the hurt locker guy, hiding behind a blast wall as the compressor goes “Hssssss”

I’ve only seen a few wheels explode under pressure when beading tires, but they were all the old style Freeline wheels (mid 2000’s) in very cold weather. It was absolutely terrifying, and thankfully nobody was hurt…

@1stPlaceMidPackGroup - Great set of videos. Thank you.

On the install video, you were applying a lot of force to get the rim into the tire. I don’t think I have the strength you applied. Any suggestions?

PS: love your name!

Fixed typo.

I did push fairly hard. I will say, I think I need to put just a bit more soap in my lube mixture. It’s not that slippery. It does take a bit of practice to get proficient with inserting the rim into the tire. Unfortunately, I don’t have any special tips, as the amount of effort needed changes depending on tire and/or rim.

I am trying to mount Vega reds on some rims and every time I try to get the tire on the rim the the tire collapses on me. Do I need to put more lubricant on the tire?

Seems like the bead face you’re trying to put on is a bit stiff may just heat it up but leaving it in the son or a bit of a heat gun blast may loosen it up and allow the tire to expand to go onto the wheel

I also had to learn the hard way that the outer rim of the wheel is a larger diameter than the inner rim…

Douglas spun aluminum wheels are the worst for me.

The rim diameter is same inner and outer.

Best I have tried is Freeline (Birel) MAG wheels. They go easy as on many youtube videos.

Medium difficult is Top Kart MAG wheels.

Warm tires seem to work better than cold.

Changing tires was difflicult for me too. I have all the tools people have referenced, except for the scissor thing. What changed the game for me was when I welded a receiver under my trailer for my tire changer. Its just below hip level, so I can use my body weight to torque tires on and off. Now changing tires is much easier for me.

I think the changer was like $80 bucks from TS Racing. The receiver was another $20 bucks, and I welded it so there was no cost there. But man did this make my life alot easier. Its a 5 min job now.