I have been having issues with wheel studs being pulled out of the hubs when i try to take the wheel nuts off. For context, I recently got new wheel nuts and thats when the studs started pulling out. I have since replaced all the wheel studs and used red loctite to keep them in the hubs but that hasnt fixed the issue. I do use an impact tightening and removing wheel nuts, but I am concious of the issues that could cause so i am very careful. Any advice will be greatly appreciated.

I haven’t had this issue on OTK hubs, but on many other hubs before. What impact are you using and how many ugga-duggas are you giving it when you tighten it?

Agree with Tj and are you using and impact wrench or driver?

I used an impact wrench for 3-4 races and paid with my front wheel waving goodbye at me in practice 2.

Now I use a driver with 1 Ugga dugga up to the wheel and another quick one for tightness.

1)Those are self-locking and some brands/lots are super tight. It helps to run them through a tap when you buy them before first install

2) Install the studs with thread lock

3)Don’t overtorque the nuts

I found the Milwaukee M12 impact gun to be perfect, on setting 2 it torques them at 20 ftlbs which is close to optimal

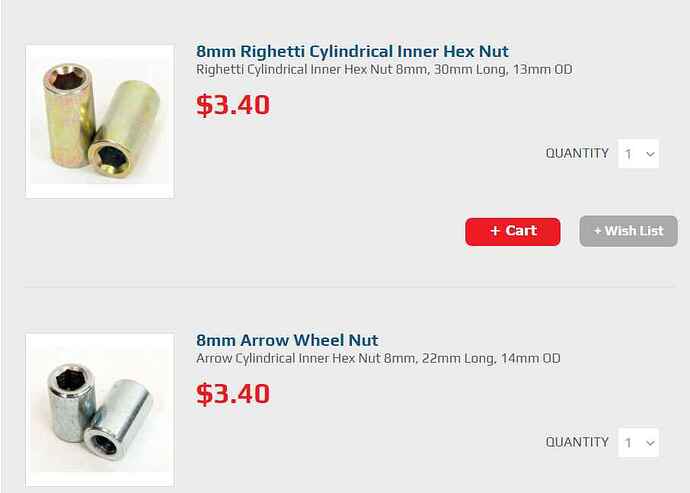

I share Derek’s garage and despise those barrel nuts BTW. I’ll take the worn out copper ones

I love barrel nuts and it’s all I use. Haven’t pulled a stud since

Derek also tried to ruin 2 sets of MXC’s because of the chamfer on the load bearing face of the barrel nuts. You need to be consistent with washer usage with them.

Same thing happened to me when using new copper nuts. As you’ve probably noticed, the end thread is peened to act as a lock nut. The only thing that has worked so far is to use my impact driver about 3/4 of the way before they seat and finish it off with a ratchet and not a lot of ooomph on the final turn. Removing is the reverse, break them loose with the ratchet and get them off the rest of the way with the driver. They’re slowly going on and off easier each time as the peen wears. Never had any issues with the old nuts, it’s only when I replaced them that I started pulling studs.

I second running the copper nuts through a tap to loosen them up.

Or buy the real barrel wheel nuts with the flat face and not the ones from that one place.

A dab of any thread locker compound should fix this issue.

I’d have to disagree with everyone on running a tap thru the nuts. Defeats the purpose of them being a deformed thread locknut. I just have a pile of them in my toolbox. Once they start getting to the point you can run them on by hand throw them away.

Edit: just saw that use said you used Red Loctite, but I do not see any evidence of it on the stud ![]() Make sure you are cleaning out the threads of old thread compound, grime and grease before installing new studs with thread locker. Give it plenty of time to cure. If it’s too hot or cold in the shop take them inside to cure over night.

Make sure you are cleaning out the threads of old thread compound, grime and grease before installing new studs with thread locker. Give it plenty of time to cure. If it’s too hot or cold in the shop take them inside to cure over night.

Keep in mind that you can vary the holding power of loctite by varying how much you apply. In most cases a use a small amount but in this case you need to use plenty. As mentioned make sure the thrrads inside and out are cleaned first. Tighten the wheel studs very well in the hub. Using a used wheel stud may help too, or run it in snd out a few times to take off any coating. A good example is sparkplugs. The silver coating is made to be a form of anti-seize. The first time the plug is removed the coating sheers to prevent it from getting stuck in the cylinder head. Not sure this applies to wheel studs but it can’t hurt. If all that fails then you are over tightening the wheel nuts. Good luck!

Yeah I had the exact same issue. Those nuts suck. I’d run them through a tap and dye set or just switch to a different kind.

When I apply thread lock - when I want something to be removable I only apply to one part. If I want to make a more permanent joint I apply to both. Then all the possible cavities in thread root or side are filled

After coating the stud - put a drop of thread lock in to the hole too. Sometimes just coating the stud doesnt work. Most of the fluid gets wiped off at the entrance and theres like nothing entering the hole

I had the same issue with those copper nuts. I also switched to barrel nuts and have zero issues since!

I can’t remember if it was Fastech Racing or Comet but someone sold non locking copper nuts.

Personally we, now that we have had and learning from mistakes, usually for the first couple tire mounts we tighten them up with a ratchet, then once its easier to take off then impact. That way you keep the locking ability to the best right away.

Edit:

Bang

I’d double nut when installing the stud and torque to 30-35 ft lbs. Also use red loctite. If it feels like it’s stripping then the hub thread is no good.

Also, don’t use a giant impact driver they over torque the nut. Use some of the smaller impact drivers. I’ve had really good luck with the Milwaukee M-12 product and I always use the copper nuts.