I have a lot of respect for those that want and have the guts to experiment, please let me know how all that goes, most of the experiments that I’ve done haven’t been successful, trying to get more power from these engines is not easy, most of the time you either get disappointed or end up causing damage, but it is definitely worth trying.

When it comes to the Super Shifter, I’m not sure you need more power

it has plenty of it, it really is a rocket

it has plenty of it, it really is a rocket  , well… sure why not, we all want more power don’t we!!!

, well… sure why not, we all want more power don’t we!!!  So go for it!!

So go for it!!

I know the app you were using, and yes that app is only good for the Super 175, with the HB-10A (I sent an email to the guys that created that app asking them if they could renew that app and include the carburetor HB-15A but they never replied to me, and read a number of comments of people that had used that app and they were complaining about the app not being of much use  So even if they eventually add the Tillotson HB-15A to the app, I’m not sure if it will work

So even if they eventually add the Tillotson HB-15A to the app, I’m not sure if it will work

Let’s see, settings for the HB-15A would be very similar to what they wrote inside your box, so Air 1:15 that for sure, Low 1:30 although depending on the circuit you can go to 1:25 to 1:40 so if you have very tight corners go for 1:25-1:30 and if you have wide fast corners go for 1:35-1:40 and High 1:40 (for sure not 2:15, that’s way too rich) but once again if you have very long straightaways go for 1:40-1:45 and if the straights are not too long go for 1:35-1:40 (keep an eye on the EGT.)

Now, here are a couple of things to really pay attention to:

My HB-15A carburetor came with a pressure spring of 42 grams, and that stupid spring drove me crazy for many months, the engine in a couple of very tight corners would die, it didn’t have the response that it’s supposed to have, I was closing the Low to 1:05 in order for it to work properly, until one day I made a couple of phone calls to some people that have a lot of experience with this engine and they said “well, you didn’t replace the pressure spring? You must use a 46 grams spring or it will not work properly as you come out of those tight corners”

So, I replaced the pressure spring from a 42 grams to a 46 grams and Bingo, that engine is flying out of every corner, what a difference

So check your HB-15A and see what pressure spring it came with, a 46 grams spring will cost you less than 1€ only a few cents.

I wish someone would have told me way earlier, it would have saved me tons of frustration, I even thought about selling the engine, even if I bought it brand new at the beginning of 2020

And then also the following… a friend from the Netherlands that runs a Super Shifter team said to me “what ignition do you have, is it the Selettra ignition or the PVL ignition?” So I checked and mine came with the PVL ignition, which is the ignition that comes with the latest engines, the older engines came with the Selettra ignition, so my friend told to replace the PVL ignition for the Selettra ignition, which is something they had done to all their new engines.

So I bought the Selettra ignition, got rid of the PVL and once again Wow! What a difference it made, the spark, the power, the sound, it just made the engine run as it really is supposed to.

So a 46 gram pressure spring and a new Selettra ignition have restored a smile on my face  I now LOVE IT

I now LOVE IT

Given that your engine is second hand, it is possible that yours is older than mine and it came with the Selettra ignition, in that case, just check the pressure spring and that’s it, you’re good to go, no need to spend 300€ on a brand new Selettra ignition.

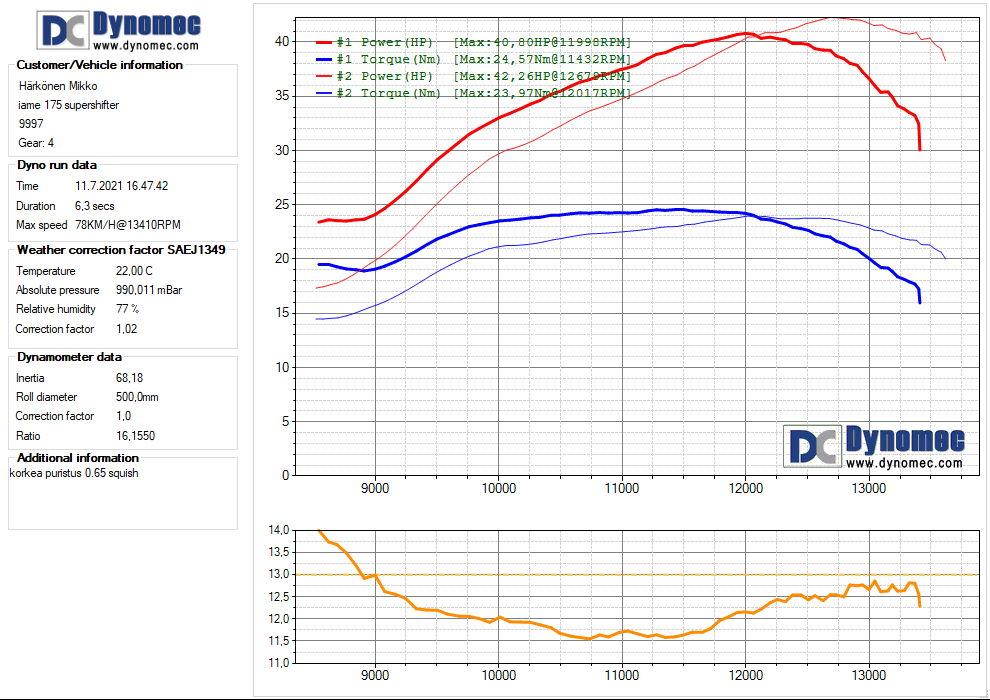

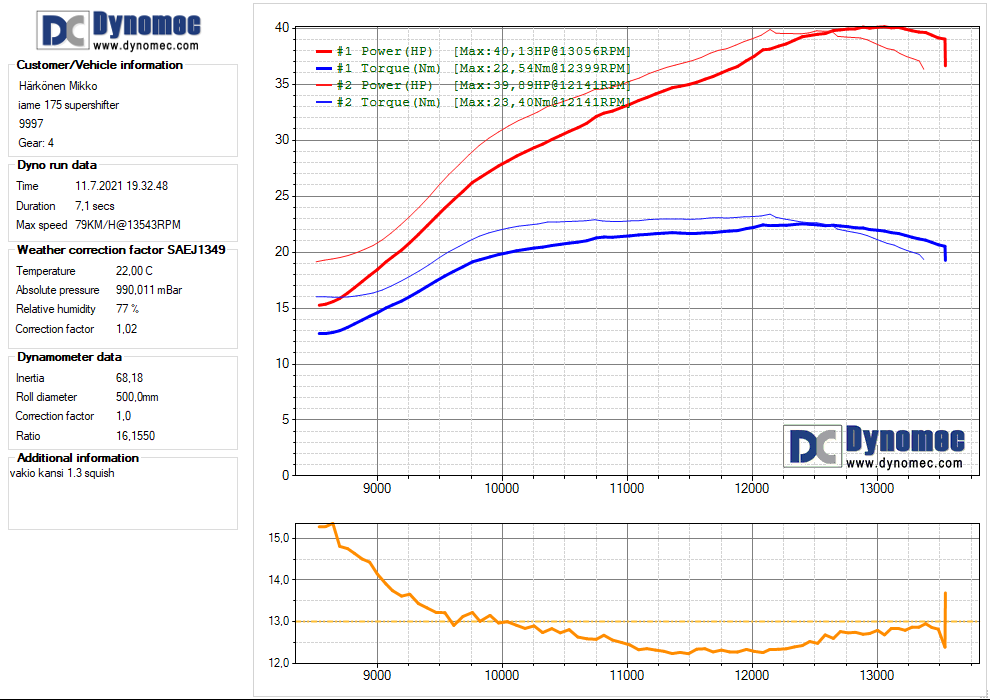

Hope that helps, let me know how it goes in the lab, be careful with the squish

By the way, if I’m not mistaken the KZ world champion will take place in Sweden this year, so that’s close to Finland  If you feel like watching proper racing

If you feel like watching proper racing

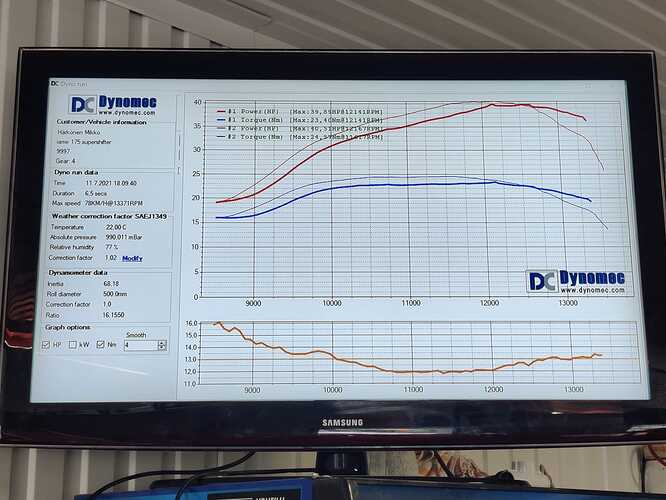

( I’ll be surprised if you get anything above 50hp or above 28Nm)

( I’ll be surprised if you get anything above 50hp or above 28Nm)