Pricing will depend on who you send it to and what you have done. A top end can cost around $600-$900 depending on the builder. I haven’t had to do a bottom end as of yet, so not sure on the cost of that, but assume it would be $1000-$1500.

Wow, I’m out of date. That’s a lot more than I would have expected. I was thinking 300 ish. $100 piston, $50 hone, $150 labor. Each number with a bit of give or take.

Yeah, I looked up what I spent over the winter for a top end. I spent $1,000, but that included $250 for clutch and driver.

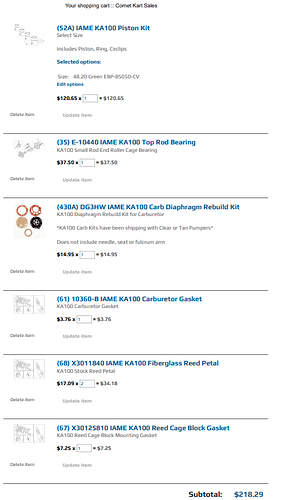

My builder changes all gaskets, top end bearings, piston ($120), reeds, and carb rebuild. It’s about $300 in parts alone.

A KA piston kit is 120. So I suppose you could get out cheap, but there is typically more to replace than just a piston.

Yeah looks like reeds are done and perhaps small end is not included with piston.

What’s the recommendation range for time between top ends services?

That’s a loaded question and depends on who you ask. IAME suggests 10 hours. I replaced this one at 14 hours as I tend to clean it and check it regularly.

I had 12 hours on my motor and honestly it was in better shape than I would have guessed. I would say 15 to 20 hours doesn’t seem unreasonable, unless you really abused it.

Oh, and the conrod bearing and piston pin is recommended to be replaced between 10 and 20 hours. The bottom end is replaced around 30 hours.

Of course, that’s why I asked for a range.

Looks like the parts for a top end service, including small end bearing, carb kit and reeds is about $218 give or take for a full carb kit, or extra gaskets. $300 doesn’t leave a lot for the builder’s time, so with those additional parts, that makes sense. You could throw in some crank seals for good measure too.

KA100 parts cost from Iame’s Aus website. There must be a link to a US one but i don’t know where.

Top end parts cost ~ $200 Aus$ assuming gaskets are changed

Plus bottom end (minus crank) ~ $115 Aus$

Plus crank and rod ~ $600 Aus$

The cost comes in for Engine builders labour and whatever Magic Sauce that they profess to use.

The top end would take a lay person around an hour

The bottom end minus a crank, around 2 Hours

Full, no idea because I send the cranks away to be split, but if you had the tools ($3000) I can’t see it taking more than 3 hours.

A good motor mechanic charges around $100 dollars here so I am at a loss to know why top end rebuilds cost over $600.

“They have to pay for their tools and expertise” - sure, but most people do have the tools, just not the confidence to have a go.

This is one of the most frustrating things about Karts for me, I have seen so many people absolutely ripped off by builders and shops who are unscrupulous. Everyone has to make money, but boy does it seem like a scam at times.

It does seem to be a bit more costly down under…

Basic tools sure, however a good honing machine is needed to do a proper top end service. On hourly rate, an engine builder is usually a precision machinist\fabricator too, I’m not sure if you can say that about most mechanics… no offence intended to mechanics.

There’s bad actors out there of course, it’s important that we promote the good guys and girls.

I just got mine back a couple weeks ago and it 925 with the dyno tune

I think a lot of the problem is comparing the cost of a top and bottom end rebuild to a top end rebuild.

A top end on a two-stroke is: drain water, remove exhaust, unplug spark plug, remove cylinder and head, support conrod with appropriate fixture and stuff crankcase to avoid dropped parts, pull circlips from piston and discard, remove piston pin & discard, remove piston and examine, remove upper rod bearing and examine, separate cylinder from head, clean head, measure & hone cylinder, select piston, install upper rod bearing, install piston and pin, install circlips, install cylinder and head, test tighten, check squish clearance, replace base gasket to set squish, install exhaust, start engine. This can be done between heats in the pits after an engine seizure with muriatic acid followed by a handheld hone. It’s an hour of labor plus the piston kit, upper bearing, and base gaskets. If you’re being charged more than $400 US on a KA100 or X30 the builder is either doing more work than this or you’re shipping it back and forth.

If you decide to replace the reeds and rebuild the carburetor at the same time it’ll add half an hour and $50-100 in parts.

A bottom end is where the press is needed - IAME recommends doing two top ends per bottom end. That involves continuing past the top end, removing the clutch and ignition, separating the crankcases, removing the crankshaft, pressing it apart to replace the lower rod bearing, pressing the crankshaft together and truing, and reassembling after checking the crankshaft and bearing bores. This is where the four-digit bills can come in, because a heavy press and specialized labor to true the crank are involved. Honda had the right idea with the disposable $125 crank and rod assembly, but their engine only turned 12800 RPM and didn’t run twenty hours on a bottom end. IAME recommends a top end every 100-150 liters and a bottom end every 200-300 liters; you’ll burn 8 to 15 liters of fuel per day of running at the track, so a typical maintenance schedule for a club racer is a midsummer top end and a winter bottom end. Be nice to your engine builder in the winter - send your engine in to be rebuilt before Thanksgiving and let him return it it after New Year’s, and he’ll have a good Christmas.

Been flirting with the idea of moving from Lo206 to KA100, but the rebuild costs and hassel of either becoming a mechanic or paying someone that frequently is something I’m not looking to deal with. 2-Stoke does seem like a ton of fun though.

Try it, you ll love it! I dont know at what level of competition you are, but a lot of the comments on costs, rebuilds etc are extrapolated from the requirements of a us national championship levels. But even more so at the club level, the engine is an awesome success, and in my opinion is the best bang for the buck. Is it as inexpensive as a Briggs? No. Is it great value? The US market says yes.

Plus, YOLO…

Don’t be intimidated by it. You don’t need to be a mechanic and you don’t need to rebuild that often. As far as 2-stroke engines go, KA is about as idiot-proof and durable as you’ll find. It’s been a boon for karting from club to national levels since it was introduced here 4 years ago. We are seeing grids of 50-60 karts at USPKS this season, which is absolutely insane. 2-stroke sprint karting hasn’t seen that level of consistent popularity in a loooong time. It isn’t solely because of the engine package, but it definitely is a factor in why it’s so popular.

All that being said, the 206 is still ideal for a newbie. No need to jump up to KA until you’ve really got a handle on the 206. It’s a great package because it allows you a lot of time to learn without fiddling with engine things too much or worrying about crashing because you’re in over your head on power.

Stick with the 206 until you feel you’ve plateaued, then consider moving to something like a KA if you want to go faster and enjoy the screaming melody of a 2-stroke at 16k RPM.

I’m with TJ. The faster classes are tempting, but I’d stick out at least one season in 206 before jumping. Even then you might decide to stick around, lots of experienced drivers stay with the 206 because it’s such a well rounded package.

Dean,

I’d move from 206 to Ka100 or even X30 at the end of the season! Someone will be selling one. Felix gives good advice - he’s the world champion and works for IAME.

Felix,

If Briggs and Stratton goes under, I have schematics of an extremely inexpensive total-loss ignition that could be installed on a direct-drive version of the KA100. It uses the coil from a Chevy van. Prototype ran well on a Leopard until the stator overheated, the updated version is optically triggered.

If you can afford it, go two stroke. There is no contest, other than financially, IMHO.