About two years ago I promised my son that if he won a national race I would build him a cadet shifter. That hasn’t happened (yet), but he won the TSRS regional champion for mini last year and some other notable accomplishments. So I said screw it and lets do it before he gets too big. I have zero shifter experience, so this could be interesting.

The major goal for the project was to make him have to think a little bit more while on the track hoping that when going back to single speed competition, there would be a little extra bandwidth for race craft, feeling the kart, etc. Another goal for the project is maximum brap to dollar ratio. A Factory kart would be great, but not in our budget. So I figured I would build it. I have a pre EVM/EVS roller sitting around the garage a slew of used parts. Being this will never see competition, and will mostly server as a training aid , it doesn’t need to be 100% maxed out from the performance side. So an older chassis will do.

I grabbed a 2012 Kawasaki KX65 for $1200 and pulled the motor. I was going to work with our team owner to build it, but he struggled to find the time. So I took it back a few weeks ago and got started.

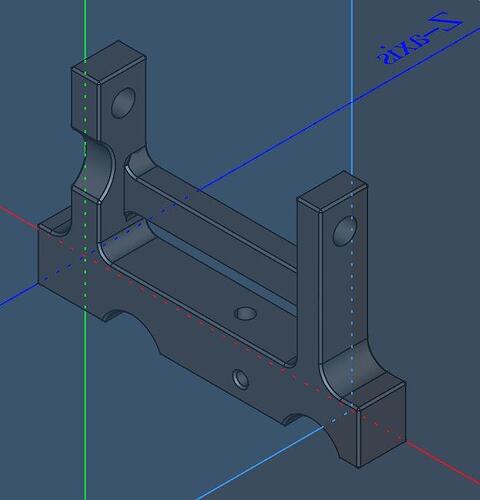

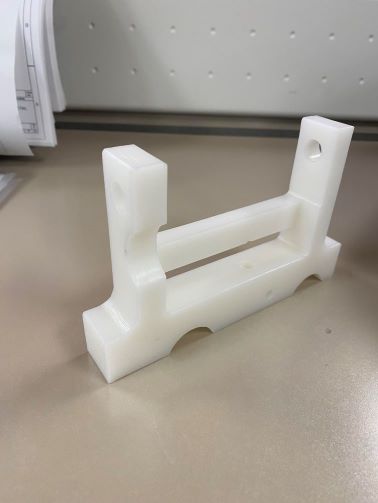

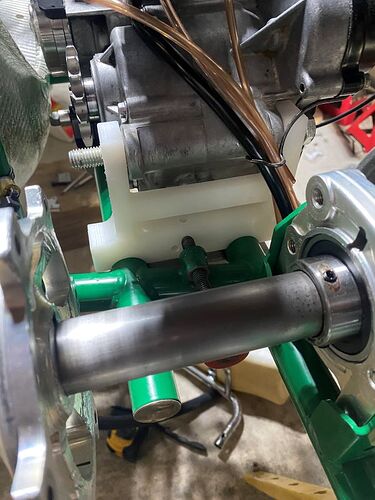

First order of business - the mount. KX65 mounts are not readily available. I contacted the fine folks at Sharkshifter and they referred me to AMC racing which used to make these parts. They had one rear mount for a kx60 on the shelf and sent it to me at no cost. It fit, but the motor was sitting up so high in the rear that the pipe was contacting the frame. It was also placing the motor so far inboard it would not be possible to put a seat in without moving the seat posts a lot. I couldn’t figure out how to make that work so I had to set it aside and figure something else out…