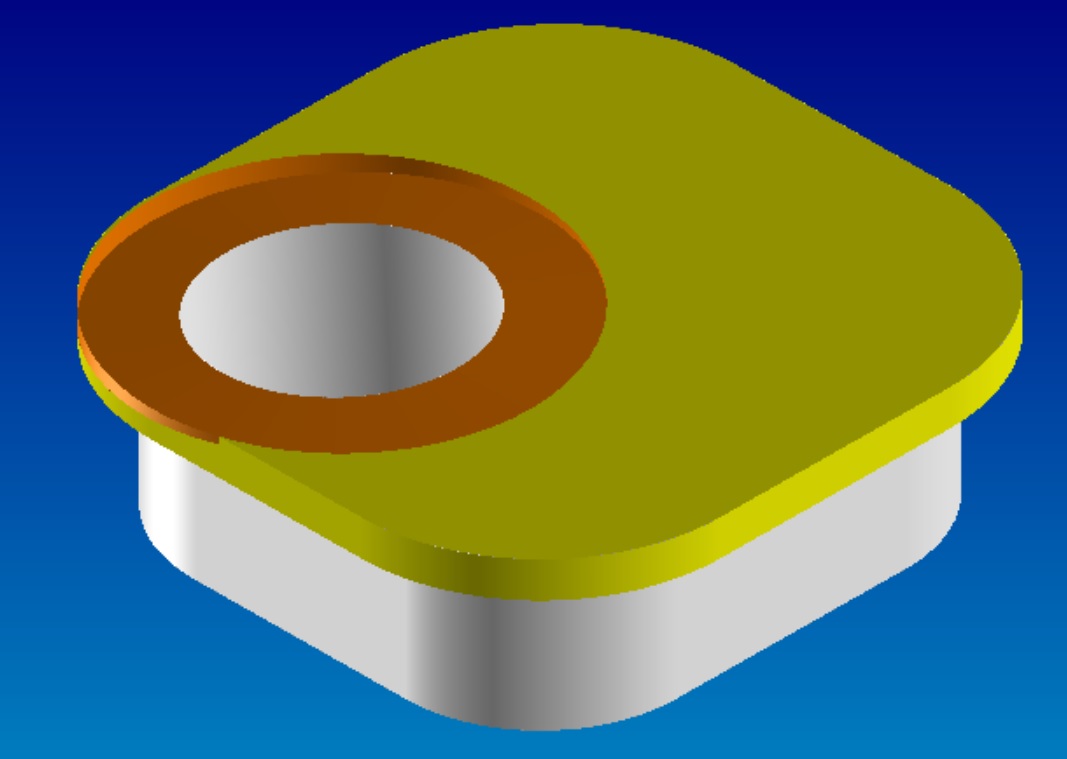

With a spindle insert like this, you can change Castor +/- 3°, while, if you want, changing camber 0° to 5°. Different inserts for different angles. In the bottom of the spindle yoke would be a ball socket arrangement for alignment.

Could you please explain exactly where and how your insert is to be inserted and how it alters the caster angle ( defined as the angle between the vertical, and the axial centre line of the kingpin bolt as viewed from the side of the kart) on a kart where the kingpin bearings are top and bottom of a tubular housing welded to the frame at a predetemined angle.

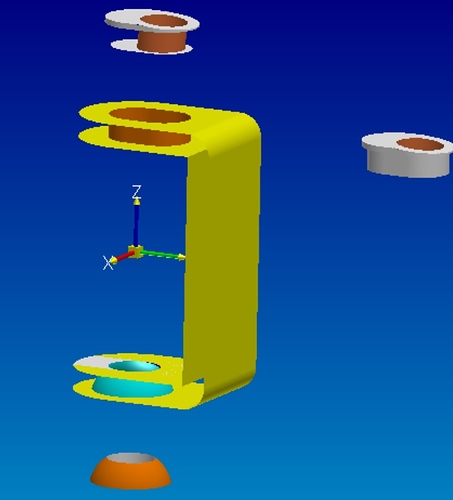

This is a picture of an earlier version, helps you see the relationship. In this version, the yoke is welded to the frame. The spindle is not shown. Does this help?

Does this help?

Well it’s an improvement on the first one, thanks a lot.

Setting up a fixture to hold the frame on a mill to machine those square holes in the C-hangers would be a treat. If someone wanted to modify their current frame to except those pills.

Is this an idea for a product, or just an exercise for explanation purpose?

What are the advantages\disadvantages when compared to, say the sniper kit?

Doing the machining – on the kart – would be a job right? No, I think it would be easier to just cut off your old spindles and weld new spindles on, or, it’s something for the kart manufactures to think about installing on new karts.

What do you think of the idea?

Are we talking about spindles, or the “C” part of the frame. I ask because the illustration looks like it’s an insert for the C, but the conversation says spindle.

I think you could make a jig\insert of some description that would make it acceptably close when milling or drilling.

“Spindle holder” would be more accurate because a lot of karts have this type of bracket welded to the frame, but not always, there are many karts out there with the reverse configuration, a short round tube welded to the frame.

What about the idea? Good, bad, stupid! lol

It’s the machining of the square hole I question. On a current frame, to do this would take a lengthy setup procedure. Keeping the clocking of the holes exactly the same side to side. Fixturing the frame to machine the same king pin angle side to side.

Yes Alvin, starting with pre-machined C-hangers then cutting and re-weld would be an easier approach. Although I like idea, and understand your view point, the Sniper system is an easier upgrade onto a “used” frame. As long as your hangers have enough material to oversize the kingpin holes.

Having only seen pictures of their system, just today, I’m not sure of all the advantages my system might have. It’s a lot simpler, I think. No measuring, just put the right insert in it. When I started this drawing I had no idea what a Sniper was, why would I lie? Sometimes, in the course of history, a need for something becomes apparent, and it just happens. Sometimes that need becomes apparent to more than one person and without any collaboration, they will seek to fill that need, totally independent of each other. Sometimes it’s just one person who comes up with a new idea. I like to think of my chain breaker as one of those ideas.

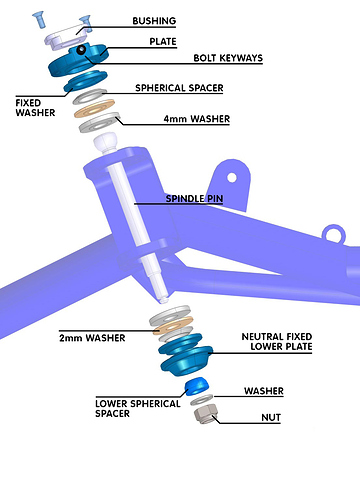

It’s similar in concept to the IPK, sniper designed, independently adjustable caster camber kits.

They use different bushings in the image below to adjust caster, and the screws to adjust camber (which is more easiliy measured).

The original sniper system that is used by CRG and others has notches for caster with each notch corresponding to a degree (i think). Plus you don’t have to take the whole spindle apart to change it, you loosen and adjust.

Hello guys,

Taking advantage of this discussion I have some questions not answered before and I think this is the correct forum?

The new systems you are talking about are being created to have an independent adjustment to camber and caster, right?

Is it to replace the old system of the eccentric pills like that one present in my kart shown below?

The eccentric pills does not allow caster and camber changes independently, correct?

Dead right on all 3 counts.

The most common system seems to be the Sniper. Details at www.sniperamericas.com

This system is fitted as standard on most CRG models but can be retrofitted to other makes.

Requirement is 22mm dia holes in the 'C ’ bracket on the chassis for the stub axle/ spindle. Usually there for eccentric pills.

Ademir - Do you have eccentrics in both the top and bottom holes on your kart?

How I was taught with eccentrics is to use the top eccentric for camber adjustment. While it does move caster slightly it’s not a huge sweep if you’re just moving camber 1-2 holes in the eccentric. It would be pretty rare you’d need to go more than 1-2 holes from neutral in either direction to get the desired camber change.

the bottom eccentric should be used for caster, and it should only really be used in either the full foward or full backward direction to not effect camber at the same time you are moving caster. The 3rd possible “adjustment” with a bottom eccentric would to be to replace the eccentric with a fully centered bushing for a “neutral” position of caster.

…that’s how the OTK manual suggests you use the eccentrics and what seems to make the most sense to me as well after struggling with them on my Birel for a couple of seasons and not understanding how to use them appropriately.

I can really appreciate the Sniper Adjusters over the OTK eccentrics. Eccentrics make it nearly impossible to fine tune Caster with out throwing off camber and vice versus. Do they make a Sniper Adjuster Kit for the OTK chassis? OTK has their set screws parallel with the stub axles where the Sniper Adjusters look like they are perpendicular. Would just have to drill out new holes on the “C”?

Yes, the set screws are in a different position and a different size. Plus the otk c section is too small for the sniper and the otk adjuster supports the spindler spacers whereas the sniper does not. You need an adapter kit for otk conversion. PKT sell one.

https://www.pktaxles.com/pkt-otk-sniper-adaptor-kit-complete.html

Good fined Nik. I like the adaptor kit idea. Potential for other chassis to use the same concept for sniper upgrade without have to ream/machine the c-hangers.

Nice!! With the holes for the eccentrics being smaller, does it limit the range of adjustment over say the CRG holes? Say only +/- 2* instead of 3*?