So as I’m getting back into karting I’m also going thorough the plethora of stuff I have. One of the engine I plan to keep around is a KT. After pulling head and cylinder, I was happy to see it’s in good shape. Hone and new piston and upper bearing should be the least needed.

But, before I decide to split the case I measured crank endplay. It’s .014", that’s a lot. Has a trend of increased endplay become the norm? I thought it should be around .002" ~ .008"?

Bore to piston clearance is at .005" and no discoloration of rod or bearing journals.

Any input would be thankful.

I’ve seen both .005 - .010 and .008 to .012 quoted as acceptable secs. That might tighten up a bit if you do new mains which you should probably do at this point anyhow…plus they are cheap.

You can buy shims in .003 sizing to put behind the mains to adjust end play if you don’t want to deal with resetting the crank at a different width.

This is a basic but fantastic reference for KT100’s that I have bookmarked and go back to form time to time.

http://kartdrome.com/index.php/engines/yamaha-engine-kt-100-tech

Final thought. I had a national builder tell me not to really obsess over end play as long as it’s ballpark. He said really trying to focus on getting near the min spec is just asking for it all to be too tight, His stance was too loose was better than too tight.

one additional thought, Almost all the good documentation you’re going to find for a KT is going to be for can motors not pipes. Pipes will need less timing, bigger squish values and a couple other tweaks. I think most everyone assumes can because that was how most of them were raced in the most recent years.

Thanks Andy

I bookmarked the page.

I’ve had the engine for probably 15 years. I ran some sprint and enduro races, prior to that it was ran at RA once a year by a friend. Neither of us have done anything to it. I plan to keep it around for the heck of it. It is a CAN, and that’s how I’ll keep it. This’ll be my first time splitting a case on one of these, so the reference page you gave should help. I’m also using the Guide from Jean Genibrel.

FWIW…I usually shot for .012" minimum on a fresh engine, but didn’t try corrective measures unless it was OVER .020"

That’s gives me more confidence that it’s OK. I reached out to one builder via Email for rebuild and dyno work, It was on the high side not seeing the engine @ “$800”. All signs are it is in good shape, but as mentioned earlier may as well do main bearings. Then at that point it’s seals, rod bearings and so on. I can do the upper myself, I have a rigid hone and can make the torque plates. I just don’t want to split the crank.

I’d think $300 is within reason. Do you think dyno time really bumps the price up a lot?

You can cut down those rebuild costs if you only have the builder do the important machine work. Send them the parts and buy the new needed parts from them. You doing the labor for setup will save you a good chunk as long as you’re comfortable doing so.

That’s the pickel I’m in. I could really do all the work, I have a full machine shop to use in R&D at work. Can’t do any of it at home, and I’d probably get the stink-eye from a few people at work for this government job. We manufacture construction equipment, it’ll look a little out of place.

If you’re comfortable enough then do the disassembly/reassembly at home and have your shop do the matching work. That way you won’t be getting the stink eye at work.

You’ll still have to invest in some tools to measure the motor and make sure your legal when assembling, but likely saves you over time compared to having the builder do all the labor.

Agree. I’ll split the case Monday, clean the parts and get some photos. Send the crank and rod out for new pin bearings. Two Cycle Technology is close and I’ve worked with them on a Leopard crank in the past. I can do mains and seals at home. Should be able to hone the cylinder at work.

Not worried about it being legal, I’ll mainly use it for open practice seat time. Running in a 4cycle class at the same track.

That brings me to asking about pistons. I’ve only read a little, but what about cutting the skirt and port timing. Do all pistons need to be cut? Or do you just size it and run it?

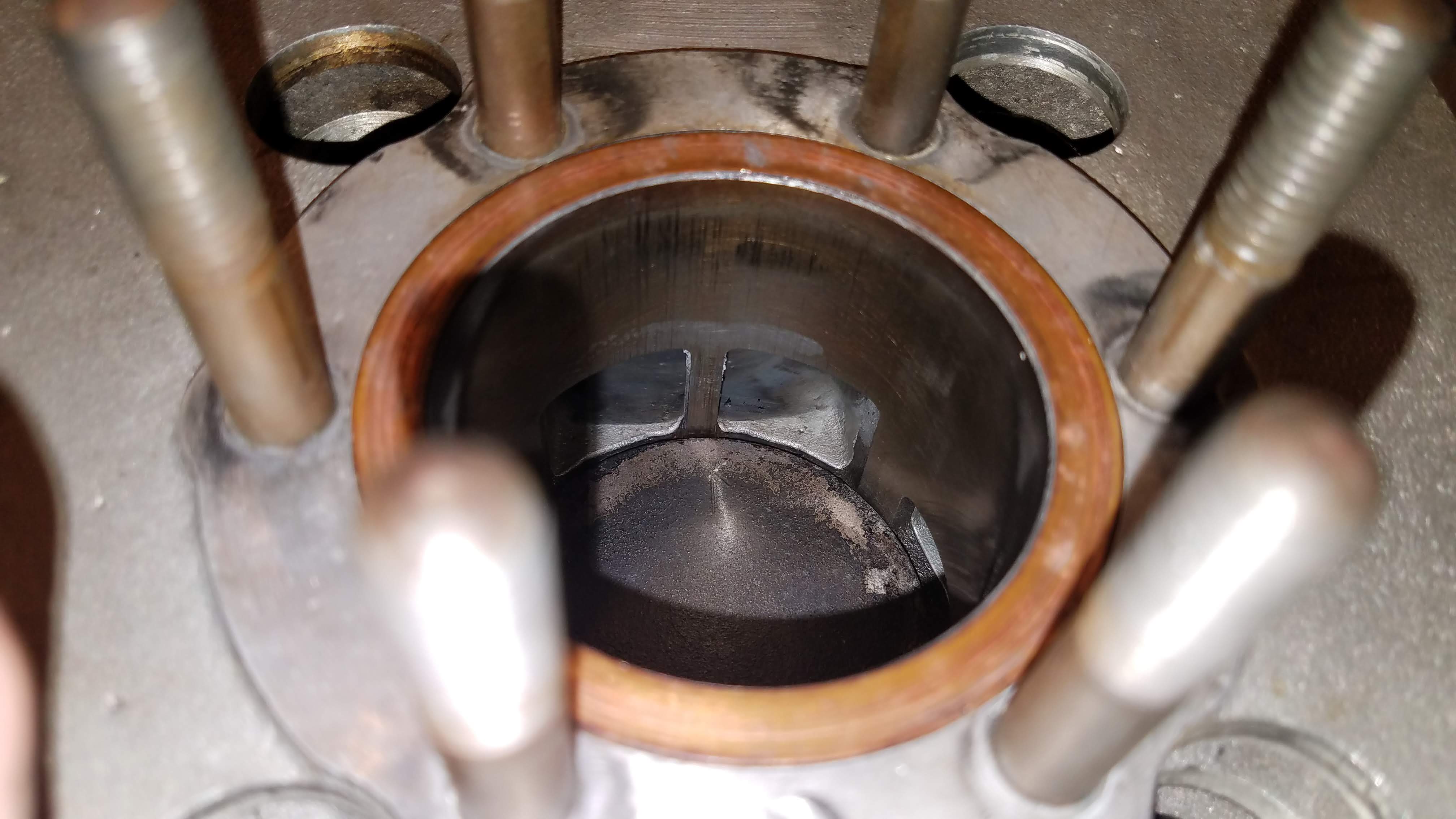

And it begins.

Comments encouraged.

A friend had ran this at enduros for two years before I got it back. not bad…

I measured bore and piston at 2.0585" (52.286mm) and 2.0535" (52.159mm).

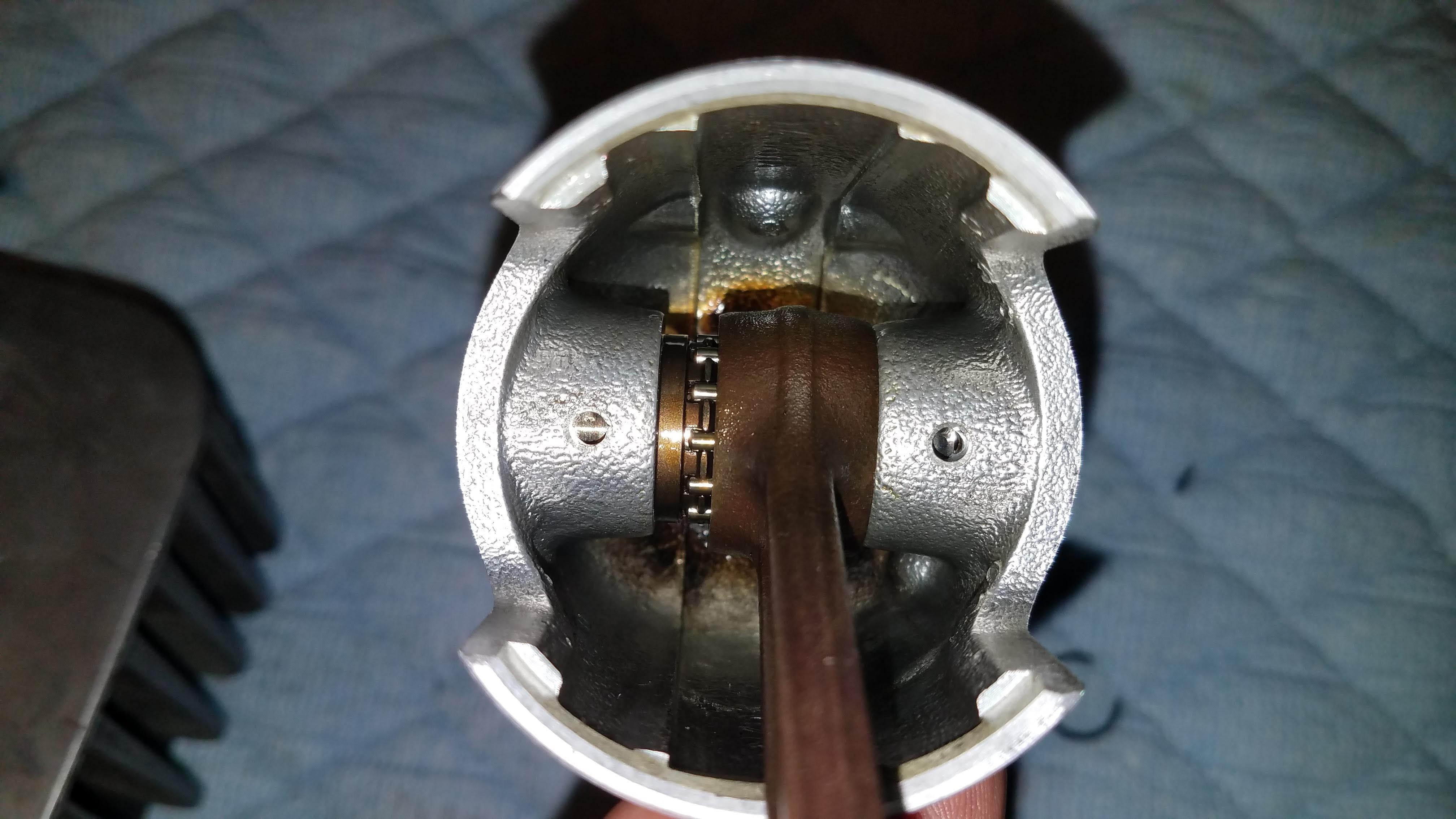

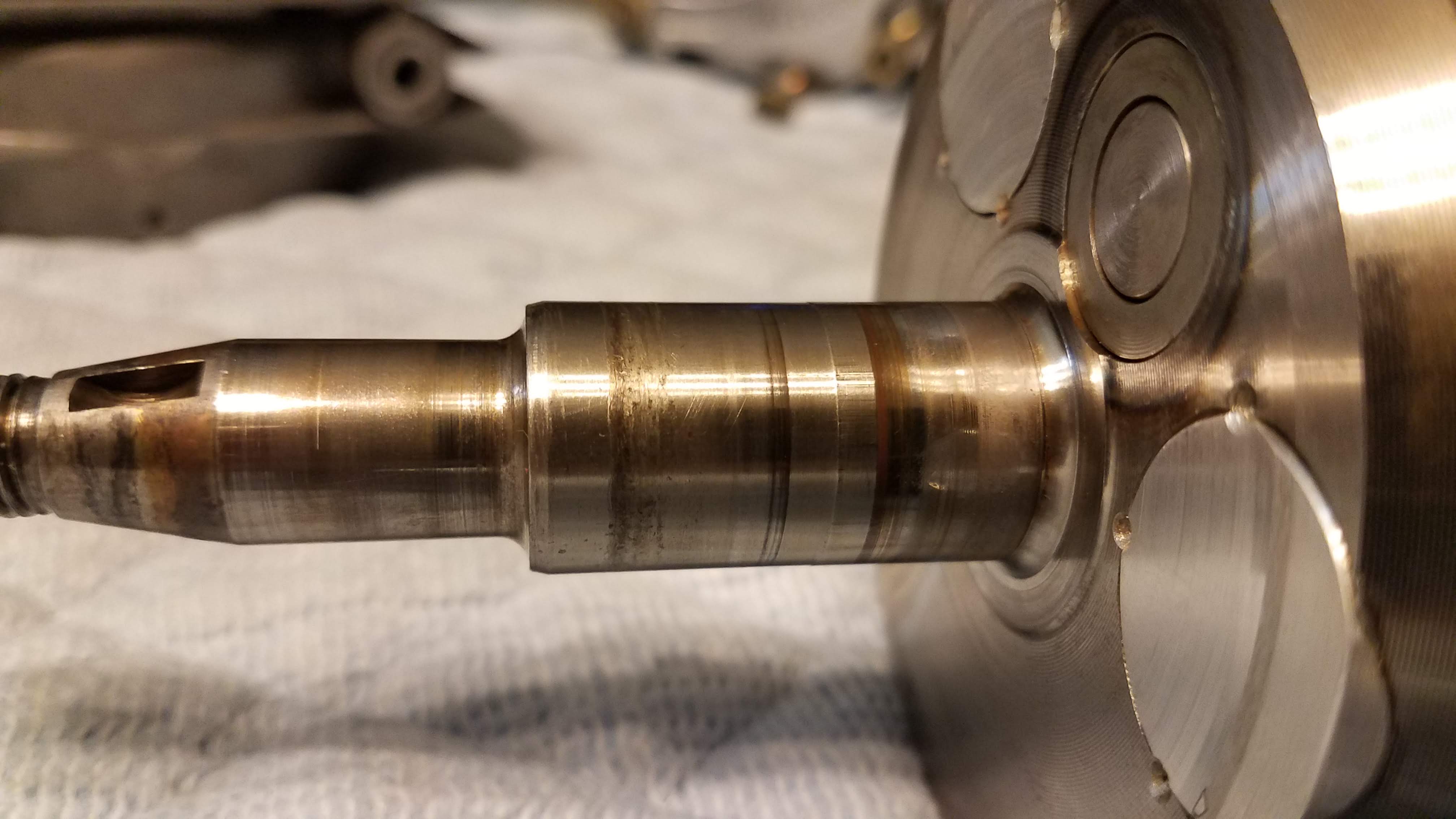

Looks like the bearing didn’t get crazy hot. Rod never got overheated. A little build-up where the seals rode on the crank.

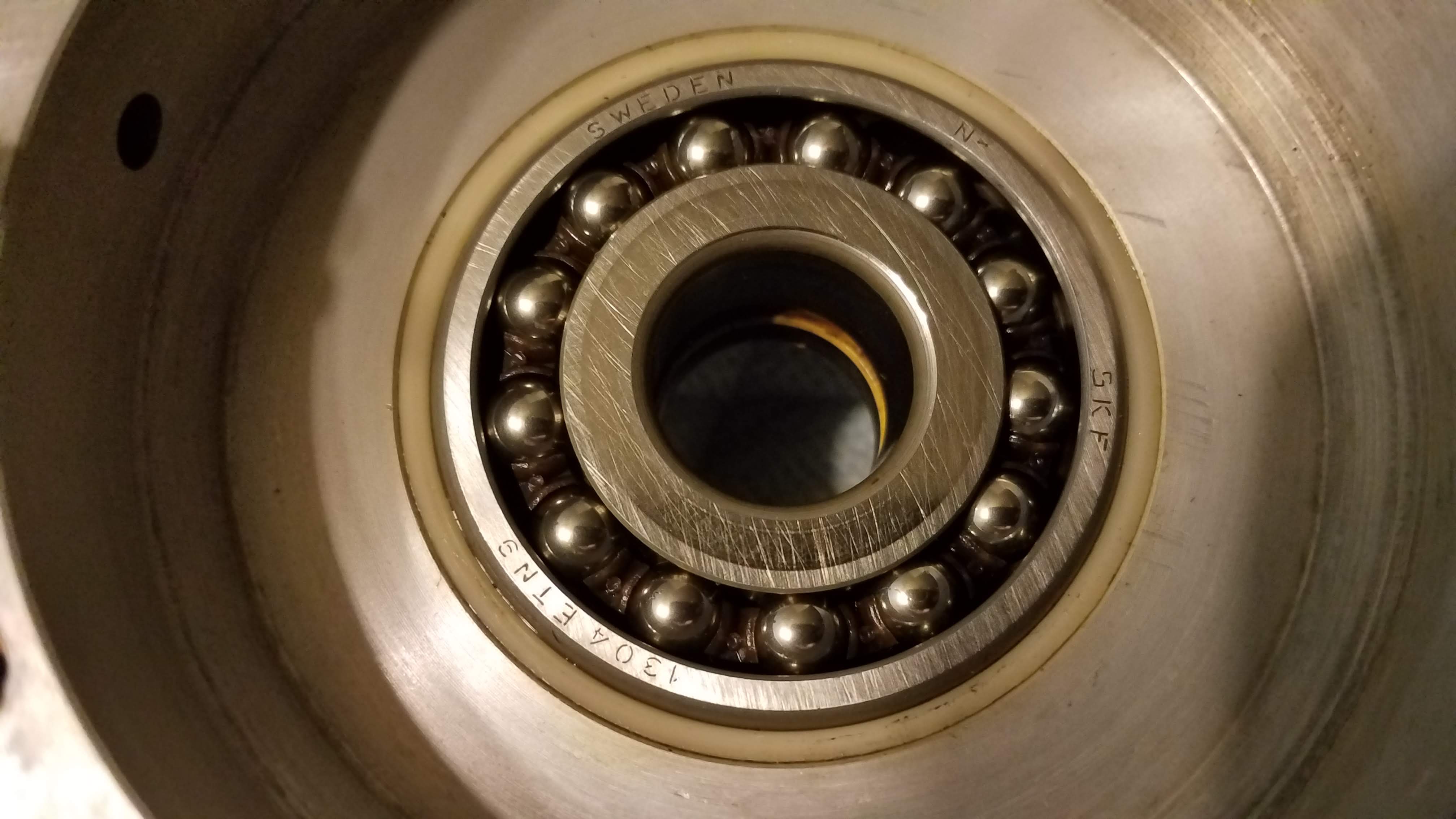

The main bearings are something I wasn’t expecting. The outer nylon shell around the outer race…what’s with that? The inner race can be move at a compound angle the center axis of the crank.

A visual of the case before cleaning.

My first guess with the nylon case on the bearing is to be able to press it in without heating the case?

IDK, I’ve never seen the sleeve but I’m no expert either… Could have been a case issue at some point that required machining out the pockets to a larger diameter. You’re allowed to machine the pockets to make sure they are true anyhow so as long as the bearing is snug in there you should be good.

Starting to see some wear on the crank from the main bearings, might be an opportunity to sleeve the crank and go to a 6205 bearing in it’s place.

Piston is def past it’s prime but the rest of the engine doesn’t really look bad at all.

Anybody have engine component dimensions?

Here’s what I’ve measured.

Endplay .014”

Base gasket .020”

Head gasket .015”

Piston 52.159mm 2.0535”

Cylinder 52.286mm 2.0585”

Clearance .127mm .005”

Crank journal PTO 19.974mm .7864”

Main bearing I.D. PTO 20.028mm .7885”

Crank journal IGN 19.979mm .7866”

Main bearing I.D. IGN 20.028mm.7885”

Seal journal PTO 19.903mm .7836”

Seal journal IGN 19.994mm .7872”

Piston pin 14.003mm .5513”

Piston pin boss 14.020 .552”

Rod small end 18.034mm .710”

Looks like the bore to rod alignment is off based on the loading to one side of the pin bosses. Not really concerned about it, not running in any competition with the engine. just going to use it for open practice for seat time to save wear on the Kohler race engine.

Crank assy. is off to get split and new rod bearing installed, cylinder is going to be honed and piston fit at the same time. Main bearings are good to go. He said they are self-aligning and a more expensive type. Run’em. Crank journals are fine.

I’ll take delivery of that and additional parts at the swap meet next weekend, and start the assemble.

The piston wear at the pin boss is not uncommon. No big deal for my needs.