Minus running the wrong fuel, that would be a lot of fun. But I’m about 310-315 total weight with no weight on my kart. You would have to be under 140lbs to run that class competitively.

Oh, yeah, that would explicitly be a light class for light drivers. We need a class for light drivers, though, and being light really improves a 100cc much more than other classes. It’s fun to watch someone driving something as agile as a 100cc on sticky tires, moves that can’t happen in other classes happen there. If being right on the edge of mechanical disaster doesn’t improve the driver or spectator experience then I don’t mind this being run on 93 octane fuel.

(light class ka100 at 320 lbs, medium class TaG at 370ish lbs, heavy class shifter at 410ish lbs is a nice split and gets you down to three adult two-cycle classes)

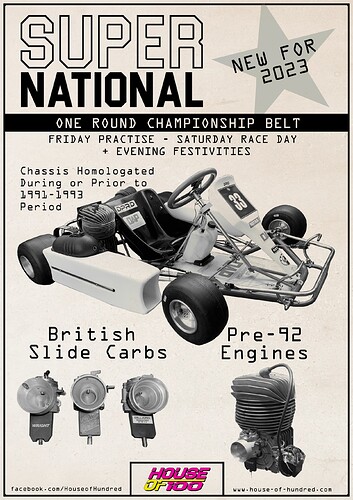

155kg aint light ![]() needs to be sub 150kg at least before we’re talking. 100 Britain used to be 132 and 100 National 135kg. Karts got BIG

needs to be sub 150kg at least before we’re talking. 100 Britain used to be 132 and 100 National 135kg. Karts got BIG

Yeah, if the lighter class really takes off then people will think about a very light class, but right now a 320 lb class just needs a 145ish lb driver, an ordinary 30mm modern kart chassis, and a lot less lead. For any of these I’m just a spectator, my 190 lb body suits a shifter best…

Hi All!

Very happy to have found this forum yesterday as I’m looking to restore my old karts/engines. I haven’t raced my karts in probably 15 years now as I’ve been busy raising 2 daughters. I would like to refresh them all this summer and get them ready to go test them in the fall.

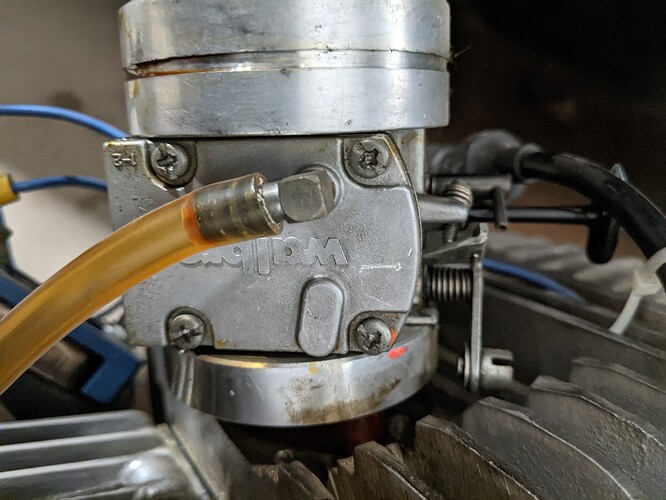

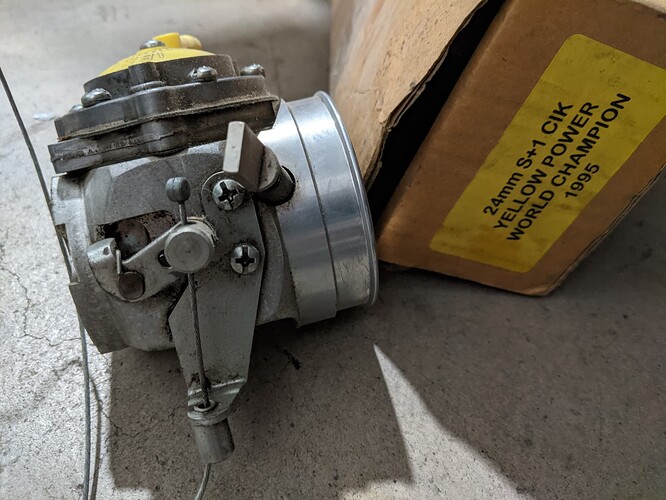

I have an old KT100 with a Walbro carb, a Rotax rotary valve (not sure which version but a 93 vintage) with an Ibea carb. I also have a Parilla Leopard TAG engine. I’ll post pictures here to help aid in deciphering.

I last used the Rotax and the Parilla about 15 years ago and they both have limited hours on them. The KT100 is of unknown hours as I don’t know how log it was since a refresh.

I basically want to get suggestions on how I should go about checking them over and what to replace. I assume I would need to refresh the carbs. Not sure if I need to replace the oil seals. Not sure where I can even get replacement parts. Not sure what else I should look out for. Also not sure where I can find bolt torque specs, disassembly manuals/videos.

Normally, I would go to my engine builder Anthony but he passed away due to Covid. I want to respect his engines and try to do the best job I can and bring them back.

Thanks all in advance for the help.

Kevin

The Rotax is a DSC. Depending on how they were stored they might be OK just having crank seals replaced. Often though you end up with a small amount of rust on the rod ends and or crank main bearings that can be terminal.

Unfortunately those parts are impossible to see with out disassembling the engine.

Worth having a look inside and try to gauge it.

Thanks for the quick response!

Unfortunately “They” is “Me” and I’ve kept it in the garage in Arizona so it’s had it’s own heat cycles as a result!

I can definitely open up the engine and take a look for rust.

I would have thought that the carbs would need servicing as I thought those diaphrams get questionable over time. Anthony gave me a pressure gauge to check the carbs but I don’t recall how to do this. Is there anywhere I can go to properly learn how to service the carburetors?

100% you’ll want to service the carbs.

This guy on YouTube has 2 good videos of re building the carbs. All the ibea kits are still available new aswell

The ibea l2 yellow power is a great carb too.

+1 on getting the big ends checked, when I got my dsc that had been sitting for a while the big end seized due to corrosion wasn’t a major issue as sorting it out would’ve been a new rod anyway ![]()

Thanks for the responses.

I started taking apart the Yamaha KT100. It appears that it’s a brand new piston. There looks like some scoring and chips near one of the ports.

If I’m correct, that was done much earlier and the engine was run after some cleanup.

The main problem I’m having is getting the piston back in the cylinder. Not sure if there’s some trick involved with these Yamaha engines?

Bit reluctant to ask this but you do have the ring gap properly positioned over the locating peg in the ring groove? If so it should be fairly straightforward just squeeze the ring imward with one hand and lower the barrel over it with the other. Bit of ‘lube’ won’t harm.Dead easy sitting here!

Thanks! Please, feel free to question everything. I may have race a while but I relied on others for doing the engine work. I assume you meant the dot on the piston for the ring gap location. That worked!

I’ll move this restoration project to new thread. I don’t want to completely hijack this one.

Dont know if this will help, just ran across this forum and your post but i have the yamaha ka-kt100 manual with engine tear down and rebuild instructions but dont think i can post files here. I needed let me know we can exchange emails or something and i can send it to you

@KartingIsLife is there a way for him o be able to attach pdf or whatever to a thread? Is it similar to uploading a photo/video?

Yep just use upload and point to the pdf. Copy/paste into the reply might work too.

TKM S89 FSA Spec tuning on Bambini TopKart (30hp + 120kg/265 Ibs) enjoy the British Singing

I was trying to jet the carb right and (only) rev 19.000 on the fast laps with the right jetting i got 21.000 but my gopro was empty. Its so much fun to drive ![]()