If you increase the squish thickness you’ll WORSEN detonation - ideally your squish gap at maximum RPM is 0.001 mm and no end gases remain in there to light off. If you have to decrease compression, increase the combustion chamber volume, but you shouldn’t have to do that on premium pump gas containing ethanol.

Ok, so in resume to have an action plan for the weekend and try to solve the problem:

I think that there is a consensus that the cause is a lack of gas - To me, it also appears to be a logical theory.

So just to start with, what would be your recommendation?

1- Bring the fuel filter closer to the carburettor, and if it doesn’t work

2- Increase jetting

3- Install the gas reservoir ahead of the carb fuel inlet

@WheelSpin I am not sure that the fuel regulator is allowed in the nationals down here, gotta check.

And also, @Muskabeatz 1 1/2 turns is literally what we are using, and we also played with this, with no results… That was a great point, actually!

Let me know your thoughts and will come back on Monday with the results…

I recommend installing the filter between the pump and the carb inlet, and if necessary raising the Y fitting to provide more pressure head. You’re probably close on jetting if you’re not running out of gas exiting corners.

This lack of response to that change is what points me in the direction of an air leak somewhere. Lack of response to idle circuit changes is a classic symptom. Since it sounded like this is a new problem for you, I wasn’t going to question the fuel setup. I’d be surprised if it alleviates the issue… but I’ve been wrong before.

There’s many causes, but a lean mixture will cause detonation if it gets too lean. Other factors: High localized temps (Which can be caused and compounded by lean jetting) .Compression that’s too high for the fuel octane rating, too much ignition advance. The wrong grade (Too hot) of spark plug can also cause detonation which can eventually lead to preignition if it stays together long enough.

I second the idea of an air leak, because you are saying it only appeared after the overhaul and your friend, on a leaner jetting, didn’t have the same problem. To pinpoint a possible air leak quickly, you can use an old school (and somewhat unsafe) method.

Run the engine at idle, spray starting fluid in the key spots (just a little and in small bursts, stay away from exhaust). By the intake manifold, pulse line fitting, cylinder base and oil seal-ignition side etc. If you notice engine rpm changing, you found your spot. If you find nothing, it’s most likely the oil seal on the primary (gearbox) side, which sometimes can be accompanied by excess smoke at the exhaust and burnt residue on spark plug and top of piston. Generally, TMs are not prone to these problems, but like any other engine oil seals can get damaged upon installation if they catch a live edge.

Dear all,

As promised, the results of the tests we made this weekend are the results:

Indeed there was an air leak in the intake manifold - We replaced it, and instantly we noticed a change in the EGT, but not where we expected it to change. It cooled the top EGT and not the low EGT. Top EGT dropped 100C (158 jet) - From 670C to 570C - But not the low EGT - It kept around 480-500C.

So we went from 56 in the low jet to 64, bringing the minimum EGT temp down to 425C as we desired.

Now, we cannot get to the right temp with the top EGT - Even going from the 158 to the 152, it didn’t get the temperature up to 650C.

That was the weekend - We had a mini race this weekend, so we couldn’t do a lot of tests, and yesterday afternoon, it started to rain.

To resume, indeed, there was an air leak in the intake manifold - We had to go very high on the jetting to bring the min EGT to the range we wanted, but now we cannot heat the top EGT enough.

@Andy_DiGiusto will try this as soon as I can - I didn’t read this before. Now, the question for you is, by idle you mean in neutral gear or just on the kart trolley? Any specific gear? Any specific RPM range? By starting fluid, do you mean a WD-40 or any other fluid?

Let me know, and we will do so as soon as we can.

Thanks for the huge help.

Thanks for reporting back! Glad we got one issue out of the way. On the top EGT, are you comparing that with others on the same day? Just want to be sure you aren’t’ chasing numbers for the sake of it. Rain conditions will indeed lower the high temp, but I’m pretty sure you’re aware of that already.

How is the engine performing?

To chase leaks, I meant this

but any combustible spray works like carb cleaner etc…some use WD-40 too to be safe. I simply set an idle in neutral, as it’s easier to pick up a change.

As for EGT, this is a comparison to what I saw few days ago on my engine (R1, so not exactly the same):

Temperature: 98F

Atm pressure: 1012

Humidity: 34%

Altitute 440ft

Dellorto VHSH 30 CS (blueprinted version)

Jetting:

B48/60

DQ268

178

Valve 50

K98 @2.5

Air screw 1.5

At that, I was running 430C-605C on the EGT, pretty much spot on, confirmed by plug reading. If I were racing, I’d have dropped few points on the max and maybe switched to a K28 needle, but that’s it.

Top EGT should be 600 (safe) to 615/630 once you are really comfortable dialing things in. 650 in my opinion is a little high. What’s the spark plug telling you?

I second what James is saying above…besides the readings, how’s the engine performing now?

@KartingIsLife Hey! Yes… Well aware of that already, but always good to confirm!

We had another driver with the same engine running EGT from 425C to 640C, so that was very reasonable to chase.

@Andy_DiGiusto and @KartingIsLife engine is performing well with top speed as high as the others (130km/h), but I believe that being in the right range of temperatures, my top speed can be even higher than the others by 1 or 2km/h.

It is just weird that my engine is asking for way more gas than the others - Maybe there is something else to be discovered - I even thought about a new air filter?

On the left side of the piston looks like little melted, did you checked that?

My

Hello there,

I am sharing my experience, withe my kz 10c . might help you to see bigger picture of the jetting and the setup of your engine.

My setup is:

- Ignition advance is around 1.6mm

- squis

h is se tted to 1.1mm - piston is 4° with matching c+3 dome,

- spark plug ngk br11 or br 10

- carb dellorto VHSH 30 (9gr floater setted to 16mm)

- 98-100 ron normal gasoline with 1:24 mixture ratio of oil.

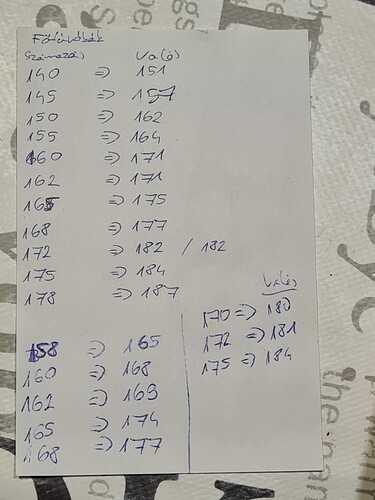

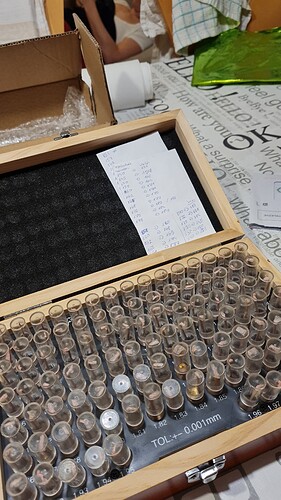

I am using calibrator set to verify the exact size of each jet. Idle jets usually 2-3 size bigger than the mark, main jets usually 7-12 size bigger than the marked.

Once the basic setup of the engine is proper and the jetting is matching with the ambient than is enough to play with the needle position or, quarter of the turn with the air screw.

I am sharing some screenshot of the jetting app result and my last round mychroon screen.

The experienced told me to set max egt aorunf 680°C is the racing condition. Normal track day reccomend to set around 620-640°C than is the lifetime of the piston is gets longer.

The low jet (with low altitude and not extrem temp) I would stick around 58 and the idle emulsifier is around B48. As some of you guys mentioned good to check for the air tightness after the carb.

Hey @Math!

Sorry for the delay, but here we are again… The engine setup you posted was kinda similar to mine, but now we are suffering with the high EGT temp that sometimes doesn’t get above 610.

We increased the low jet, using the 58 or 60 all of the time and the high jet sticking from 148 to 152 depending on the temperature. Down here in Mexico, altitude is high wherever you go, so in the Formula Karts Nationals, we are only allowed to use the K98 needle and only when we go down to cities below 1,000 meters of altitude we are only allowed to use the K28.

The similarity I see here is that you also cannot get your low EGT value to below 450, so maybe we have the same “problem”. Down here, all of the guys run with their EGTs below 450. Tried increasing the low jet, but the kart just suffered from an excess of gas on the exit of low-speed turns.

Still looking for the answer to get it down below 450 EGT and will come back as soon as I get the issue solved or. If anyone else has a solution… Very much welcome!

Hello Rodolpho,

Jep, the altitude is the same keyfactor as the ambient temperature. My bottom end egt temperature has been recorded at 37 °C outside temp.

My friends also suffering to get the max egt above 640°C we have tried several setting, nearly no changes.

Did you calibrated the main jet? Size 158 usually marked around 145-150.

I curious of your result too.

Cheers

//Matyas

Hey Matyas!

No matter the air temperature, we never manage to influence the engine temperature as we want to. It always lacks a bit here or is a bit over the target temp over there.

As for the nationals, we are only allowed to use the K98 needle, and the 267, 268 or 269 atomizers - What I found that works best for me here is the 150 high jet, 58 low jet, and 268 atomizer with 2 turns of air.

With that, we are more or less inside of the range, lacking temperature on the top end and kinda in the target on the bottom (right in 450).

Jonathan Thonon is coming down this week to drive with me and surely he will find out what could be possible happening and I will post it here with the fix.

Very curious to see what the outcome of that is. Keep us posted and say hi/.

Now there’s a connection to have.

Hey again guys,

Sorry for the late feedback.

So, Jonathan came down and spent a whole week with me, my teammate and mechanics, and it was very fruitful indeed. To see this guy driving, you learn a lot and also, what a great person. Was driving 0.4 - 0.5 off his pace, so not bad.

Long story short, he made my mechanics replace all the needles, floating needles, atomizers and jets and it got better, we were able to manipulate the EGT temperature better, but, it really came to a solution when we used 3 turns of air in the air screw and started from there.

Using the 3 turns (we used to use a maximum of 2 turns), we were able to manipulate the temp and get the results we wanted. His response to that was to run it “cleaner” of gas.

Also always run with TM engines not more than 52 celsius degrees of temp. From 49 to 52 and keep it with this window. Forget chassis` protectors they end up damaging the chassis more than protecting it.

Will maybe see you guys in the supernats in 2 weeks.

What a cool opportunity to work with such a legend.