Does this beast have a name yet? Was the shakedown successful?

Unsuccessful test day. In our mad dash to finish a collar did not get tightened on the axle, which let a sprocket move. Got everything fixed and was warming it up to go back out and that’s when we bent an axle, we think from the chain whipping the axle (which is why we added a 3rd bearing).

Hopefully got a few problems sorted for the next one.

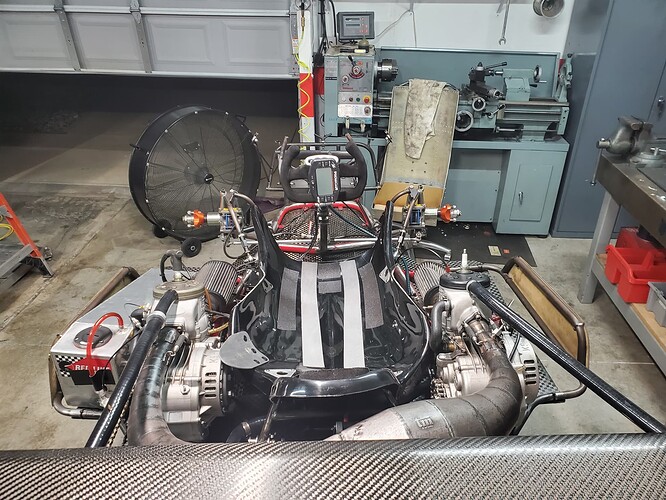

Been a while since the last update, just too busy with life. We had another failure at Lake Afton with the shift linkage. To say we were frustrated would be an understatement. We made the call to pull an engine off so we could try to get working on development with other areas and re-design the system over the winter. This proved a solid decision finishing every practice and 2 races including at 45 minuter on Sunday. The build has come a long ways but still has a longer road to go for a finished product. Time to rest up and relax a bit then hit it hard this winter!

That thing is sick. I cant wait to start some kind of project someday

Fierce. Angry. Mean. Fast. Intimidating.

I would be scared if that rocket passed me, I think. I’d certainly make space!

I know that this would add weight but…

Would there be a benefit to making the nosecone and the sidepods into one continuous surface?

Yes, a huge one we think. A full body will need to be made eventually but I need to work out placement of fuel tanks, radiators, pipes, etc before committing to that process. For now we just cobbled some parts together.

Beast mode, for sure.

Will there be a Daytona appearance with this kart?

Man I wish, just not ready for it. Too much of a commitment for us to go down with the twin engine set-up still untested. Wasn’t for a lack of effort or want I can promise you that.

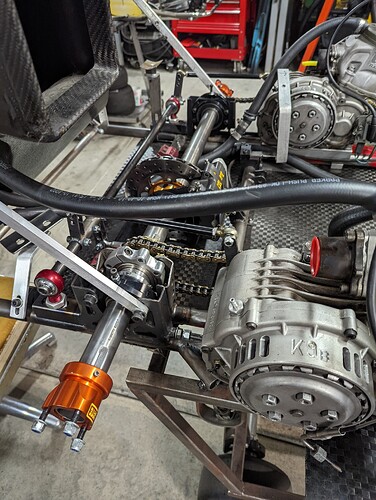

Crazy complicated looking. How critical is synching the shifting between the two motors?

That’s a nice way to put it.![]()

The syncing is absolutely critical and that is what has caused almost all of our issues so far. We have a new system designed on paper and will have it installed ready to run for next year.

Must say I’m impressed with your engineering!

Finally got back out last weekend. New bump style shift setup appears to be much improved. We made laps and were progressing until getting rained out. We topped out on gearing only 1/3rd of the way down the straight, was already going 113mph at that point ![]()

Back to work now, more stuff to improve upon before KART Nationals at Heartland Park.

Way to long without posting an update here, kart has just been a back burner for me unfortunately.

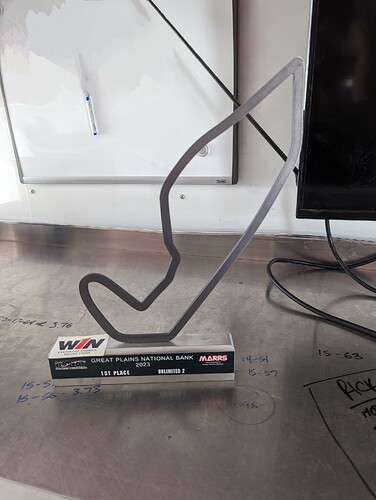

We have continued working on it however, recently re-doing the nose and front end along with some other changes. We recently completed every practice lap/session and a 30 minute race without issue at Lake Garnett, finally bringing home a win. After the race we discovered a larger issue, that we were only hitting 5th gear. That’s an entire other post, but data shows that with 6th gear the kart has potential to go 155mph+. We will hopefully find out soon at K.A.R.T. Nationals soon this summer August 18th-20th at Heartland Park Topeka.

That kart looks so damn sick. Shared on our FB page. Anything I can tag for it?

I know right? Meanest looking kart on KP these days. Hope the bodywork someday gets made.

Can someone answer how it is that you synch two engines to turn the axle the same speed etc?

Thank you James! You can tag R3Speedfab, LLC on FB.

Really appreciate the comments. Trust me, I want to develop the body but it’s just such a huge time/financial commitment and with my sons racing a priority and our business second after that, this is really far off. I do have a bubble idea that we will have on for Topeka and I have some old PVP side pods that we are working to modify.

Regarding the sync of the axles, here is a picture of the new linkage design.

Happy to try and answer any other questions y’all may have. Thanks again!

On a basic level, how difficult is it to get both engines to produce the same action at the same time at the same force? I get it that both engines get their “go” signal simultaneously since there is one throttle. How does one deal with the variance between engines? Presumably they both have to exert the same torque at the same time otherwise it would twist the axle?

On my karts the throttle is a simple cable mechanism that pulls a butterfly on the engine, basically. I am assuming that when dealing with two engines that this is not the case and that its a bit more sophisticated. Is there some sort of ECU that facilitates two engines working together?