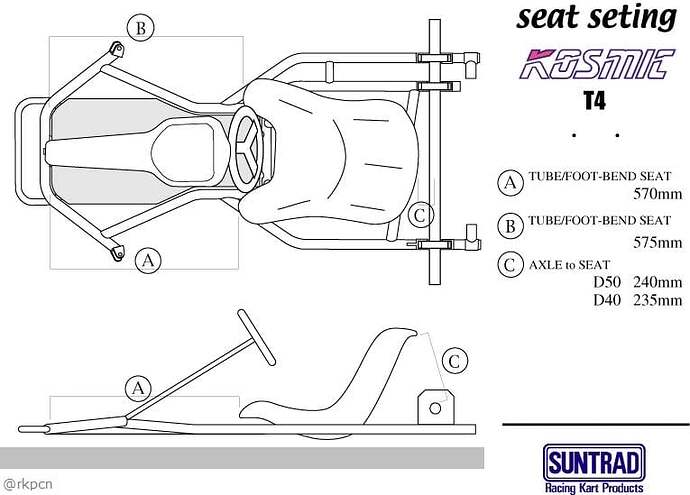

Very tough to find specs, but for the shakedown I’m going to run baseline setup as above, 10mm wheel spacers each side which result in a front width of 1,100mm while the back I will set it at 1,395. Seat was placed per historical spec, plus some cheating…had to move seat back to make my legs fit under the steering wheel, so I’m curious to see how the balance will feel

Planning to fire up tomorrow and hit the track on Sunday for a shakedown. Most likely with incomplete pod set, I’m still trying to find a silver front bumper

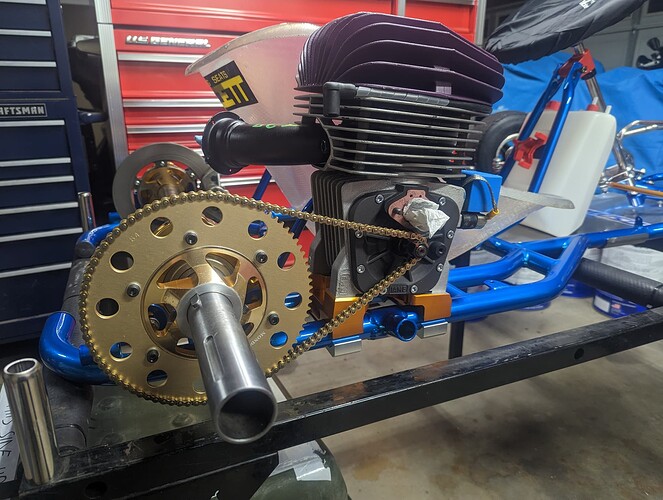

The engine sprocket has maybe 4 teeth?

Looks a bit short-geared for Apex. I’d recommend gearing for about 72 mph (32 m/s) at 18000 rpm.

With a rear tire circumference of about 860mm, 32 m/s is around 37 rev/s or 2250 rpm, so the desired gear ratio is 8.05:1, so 10/81 or 11/89 if you think an 89 tooth driven sprocket will survive around there.

Close!

I’m actually running the “big” engine sprocket…on these you’d typically run 9 or 10 teeth on the engine side (in the picture I had the 10) and 79 to 88 on the axle (84 in the picture, as I’ve cut the chain with the engine in the middle of the adjustment range and using a “middle of the road” sprocket).

Good point Charles probably I’ll use an 80 or 82 for the first test at Apex, given the long straight

btw, very nicely done restoration.

I will take one. Prefer a Comer though. ![]()

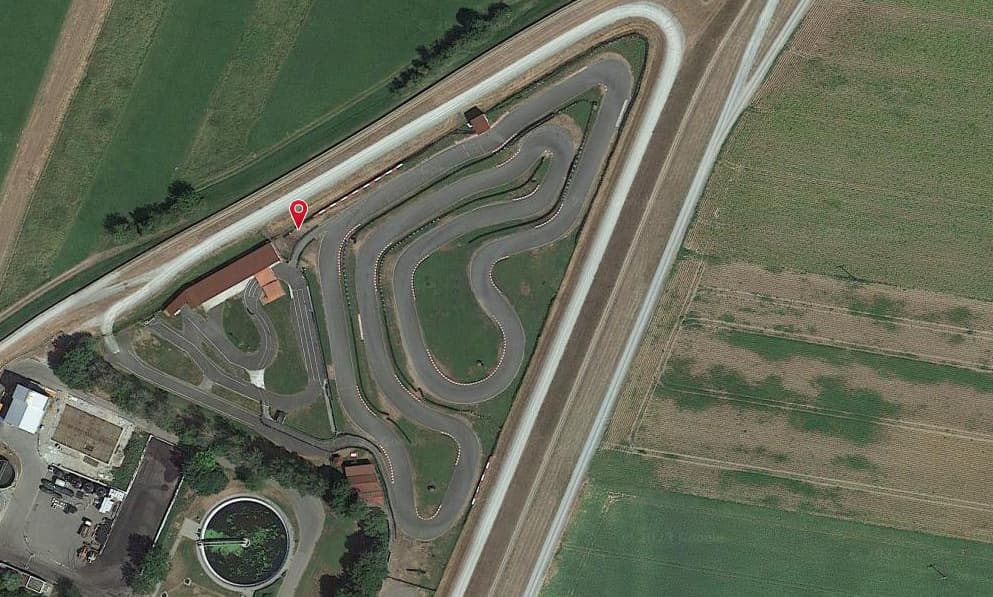

Gearing for Adams and Apex is the same, and Adams has an enormous advantage for the direct-drive karter. There is a steep downhill grade between the upper and lower pits with a straight shot onto the track!

I don’t know if racers in the US got softer 9T sprockets or what, but we ran them all the time on sprint tracks over the pond.

9:80 gets you a lot more ground clearance for your sprocket vs 10:88. 11s we only ran on road courses, and even then tried to avoid it to reduce the chain rash on the carb (Rotary).

9:92 is front wheel lifting territory, absolute blast. Crashed my kart on an indoor track once and learned about this the hard way… lost steering right as it got up on the pipe ![]()

I was in Germany. Must have been a soft German one.

Haha fair enough. You do really need to be on top of chain tension though a lot of HP pulling on not a lot of teeth

I wonder what sort of noises it will make. Looks great.

Thank you all! I can’t wait myself, but like with all restorations I also need to deal with setbacks, I’m sharing the good with the bad here…and of course, here is the bad.

Kart is now ready, except I found this after I tightened the pinch bolt

Upon inspection, it’s not a small superficial crack, it runs almost the whole depth (you can see the crack running past the bolt in the back). The more you tighten, the more it opens. Although I was really tempted, I opted to replace the carrier before I hit the track.

And yes, of course nobody has the part in stock, anywhere

OTK still uses that exact same sprocket carrier, and it still breaks the same way. A local shop should have it. Call Adams Motorsports Park first.

Also for anyone interested, mondokart have just listed brand new CIK '02 pods for sale

The purple heat sink is a nice detail. Kart looks light and tossable.

First warm up. Oil RSK-M @ 7%, low @ 1 turn out, high @ 1.25 turns out on the IBEA L5.

Light load applied intermittently via rear brake also to keep rpm in check. Super rich and safe for the first heat cycle. Even with that, you can hear it wants to really take off past 10K.

Few goodies are still in transit, then the project is a wrap and ready to hit the track!

Here to say our 9t sprockets we use in F100 racing here in Australia last quite well, I haven’t worn one out yet.