Hi. What parts does need to be changed in a full rebuld. I know some like piston, bearings, rubber rings and some more but i would like a complete list of what i need to do. Thanks…

Download the overhaul manual

parilla_x30_125cc_rl.pdf (3.3 MB)

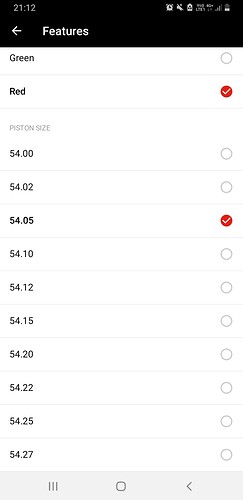

Im sorry but imma jump off bruh. How am i supposed. To know what size and color is right for x30 j125 from 2020

I’m not a 2 stroke guy, so I dont know what the colour signifies, but the piston size is dependent on the bore size. You’d have to tear it down, measure the bore, decide if it needs to be honed (probably does) then order the next size up piston and have the machine shop hone to fit the new piston.

The inside of cylinder was 54.6 i have honed it. Green means 11mm gap and red means 10mm gap…

Then decide how much cylinder to wall clearance you want, and choose the piston from that.

How does the clearance effect performance is a smaller gap more comoression. Does that give me more rpm? Top speed ? More cc

If you don’t have a dial bore gauge a 3 inch micrometer and a really good hone don’t try it and that’s just for doing the top end. Fox and sons has some really good info on there site and pricing isn’t bad.

I doubt you’ll notice.

What you’re doing by decreasing the clearance between piston and cylinder wall, is reducing the space that exists between the piston and cylinder above the piston ring. You’re reducing it below also but that doesn’t matter. Reducing it above the ring gives less volume for gas to expand into, so the same volume of gas is able to exert more downforce on the piston face.

But, the difference is so small unless you’re at the pointy end of WSK level or such like and chasing hundredths, it’s not worth the increased risk of blowing up the engine.

Just my opinion ![]()

Great Guys! I used Fox and Sons this year for my KA. Sent it in for a full rebuild but Christian said bottom was good and only did the top end.

But I think Mike is in Europe

Yeah sweden… What does the guy abobe mean that the bottom was good so only did the top. Honing??

What does every one mean with top end…

Mike, when we refer to engine rebuilds there’s the complete rebuild (top+bottom end) or just the top end.

The top end is typically the mid season refresh. It replaces the piston and gaskets (I think). For x30, I think folks that are in a competitive series for around 5-8hours on top end. I think club type folks go 10+ or so hours on the top end.

The bottom end or full rebuild is done typically at end of season and addresses more than just the piston/cylinder, it’s more involved and more expensive.

Bear in mind rebuild rates vary by engine type and competitor needs. Rotax is like 20 hrs top 40 hrs bottom or something. The person racing skusa pro tour will be doing top ends a lot more than a club racer, etc.

True but there is good info on www.foxandsonkarting.com regarding piston sizing etc.in their X30 tuning section.Certainly much clearer than the IAME manual.

I assume that Mike’s bore size of 54.6 mm is a typo as the biggest piston listed for an X30 fits a 54.27 mm.bore and is marked 54.27 to give 0.11mm clearance.

Although I have happily split and rebuilt cranks l would leave the honing and piston fitting to those with proper equipment as recommended by John Tapler above.

My dad has owned a mechanic shop 3 years ago and has all the tools so no prob with that…

What includes bottom end (fullrebuild)

So what is the bore size? Was it honed accurately round and parallel?What size is stamped on the old piston. What piston to bore clearance do you have with the old piston. All accurate to 0.01 mm.

Bottom end usually includes main crank bearings and the lower rod bearing. It may or may not include replacing the rod. The crank needs to be disassembled with a hydraulic press, new bearing added, repressed then Trued\checked for run-out.

The last part is a bit of an art. You’ll need two dial indicators, two vee blocks, a flat plate, a mallet and some time.

Looking at everything posted, I think there is a typo…I think he must have meant 54.06 bore, which means 5.05 V piston. R is 0.01 bigger

As others said, leave clearance as prescribed by IAME. You will most likely only increase chances of sticking if you go under that, it’s not worth the hassle. I can tell you for a fact past experiments with tighter piston to cylinder clearance, tighter ring gap (in theory, more compression) and thinner rings (in theory, less friction) only led to loss of reliability and no visible change on dyno. It’s much more important to keep changing parts and keep them on the optimal window instead of making the window smaller.

As far as bottom end…split engine halves, change crank bearing and seals, split crank, check conrod clearance/ovalization and change as needed, reassemble with new cage, pin and spacers, rebalance, put everything back. The crank splitting/check/balancing is one job that is better left to experts. You may have the tooling, but you need experience to get it close at first try and then adjust with fewer taps as possible. You need to go through a lot of them to get the right touch. Also, crank balancing can be done in multiple different ways, that’s why you want to rely on an expert who built his own system over time. Money well spent, unless you want to embark on a new journey