Update #2:

Time to tear trough that engine.

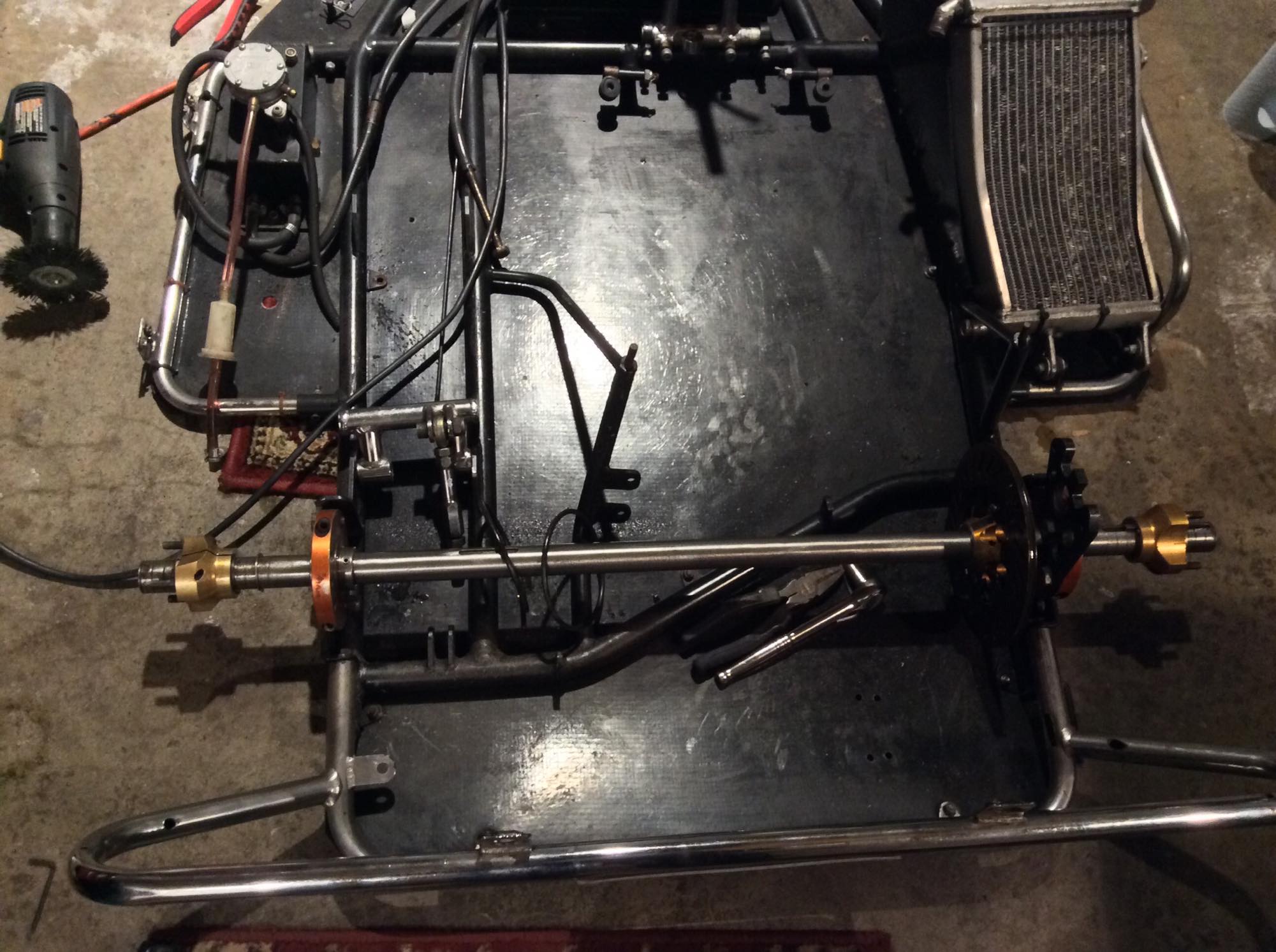

According to the seller, the chassis used to belong to and was set up by Graham Barker. It was then sold to J. Musel in Canada (I think?) and bought by the person who ultimately sold me the package. I don’t know how much run time the kart had with Musel or Barker (some clues to that further down this post) but seller states he has only raced the kart once, in Portland in the early 2000’s. Engine has a modified liner and ignition, 4.2 mm BTC.

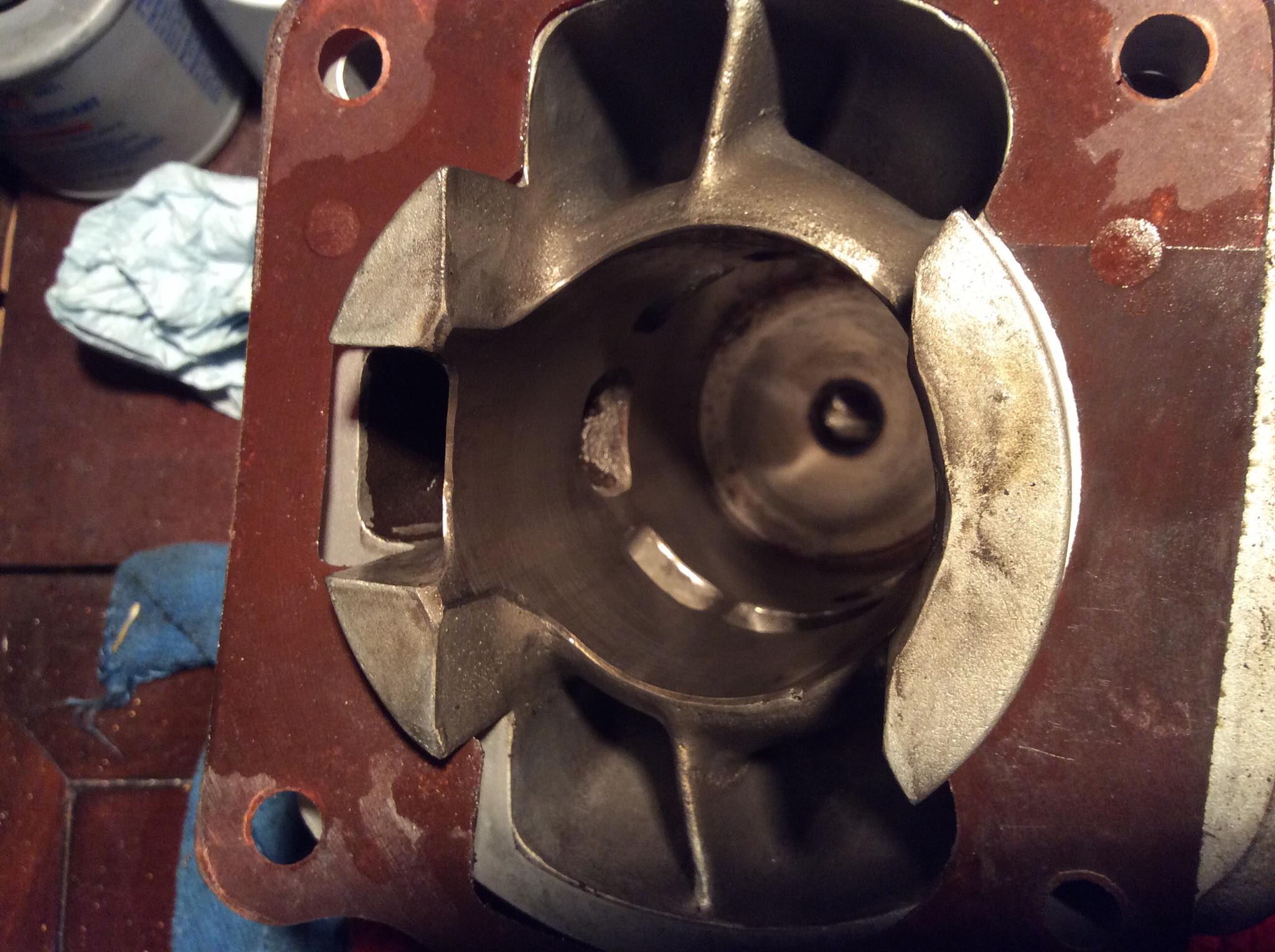

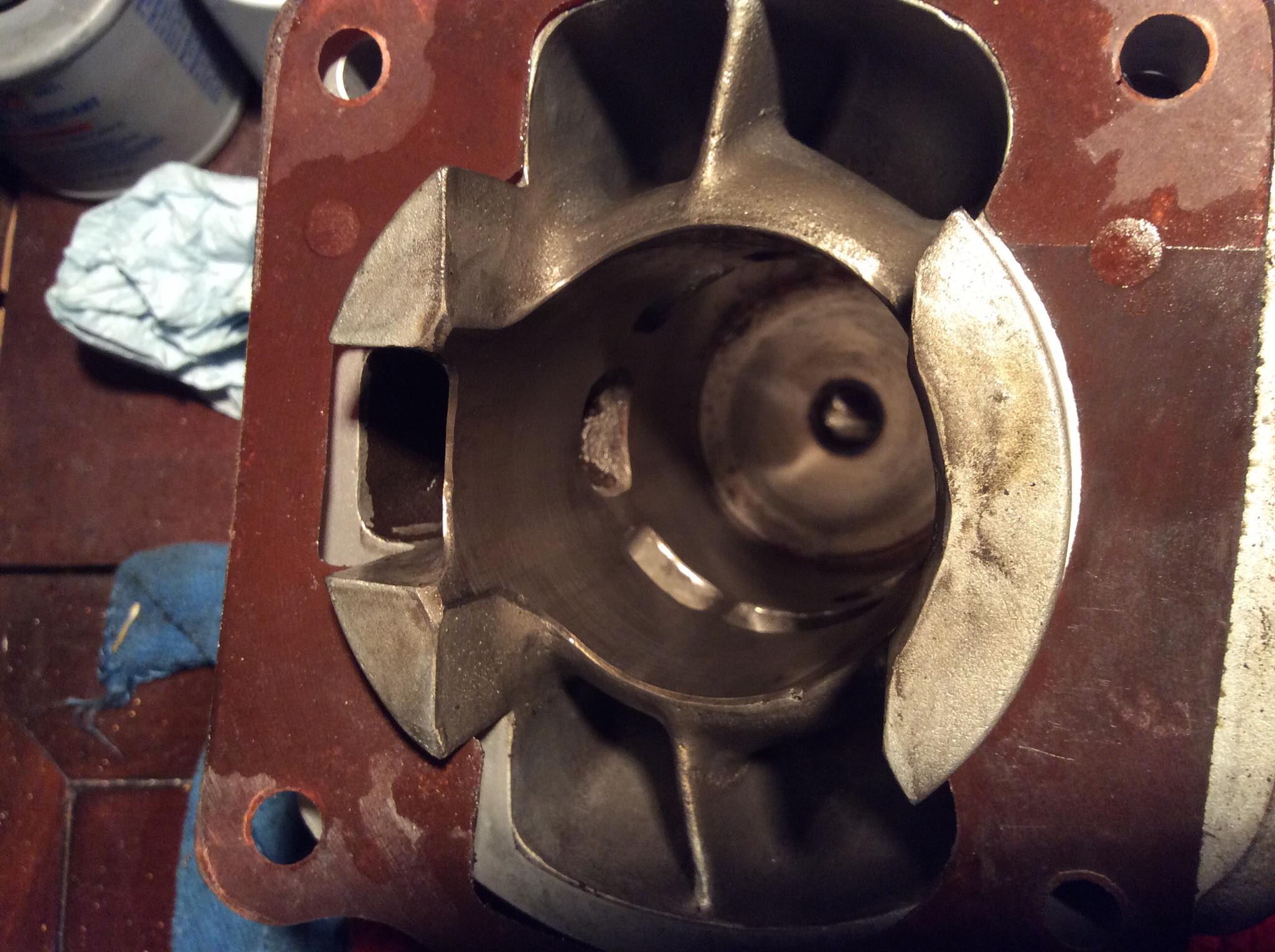

Coolant passages are really rusty. How when everything is made of aluminum?

Coolant surrounds the combustion chamber. The bolts securing it rust out.

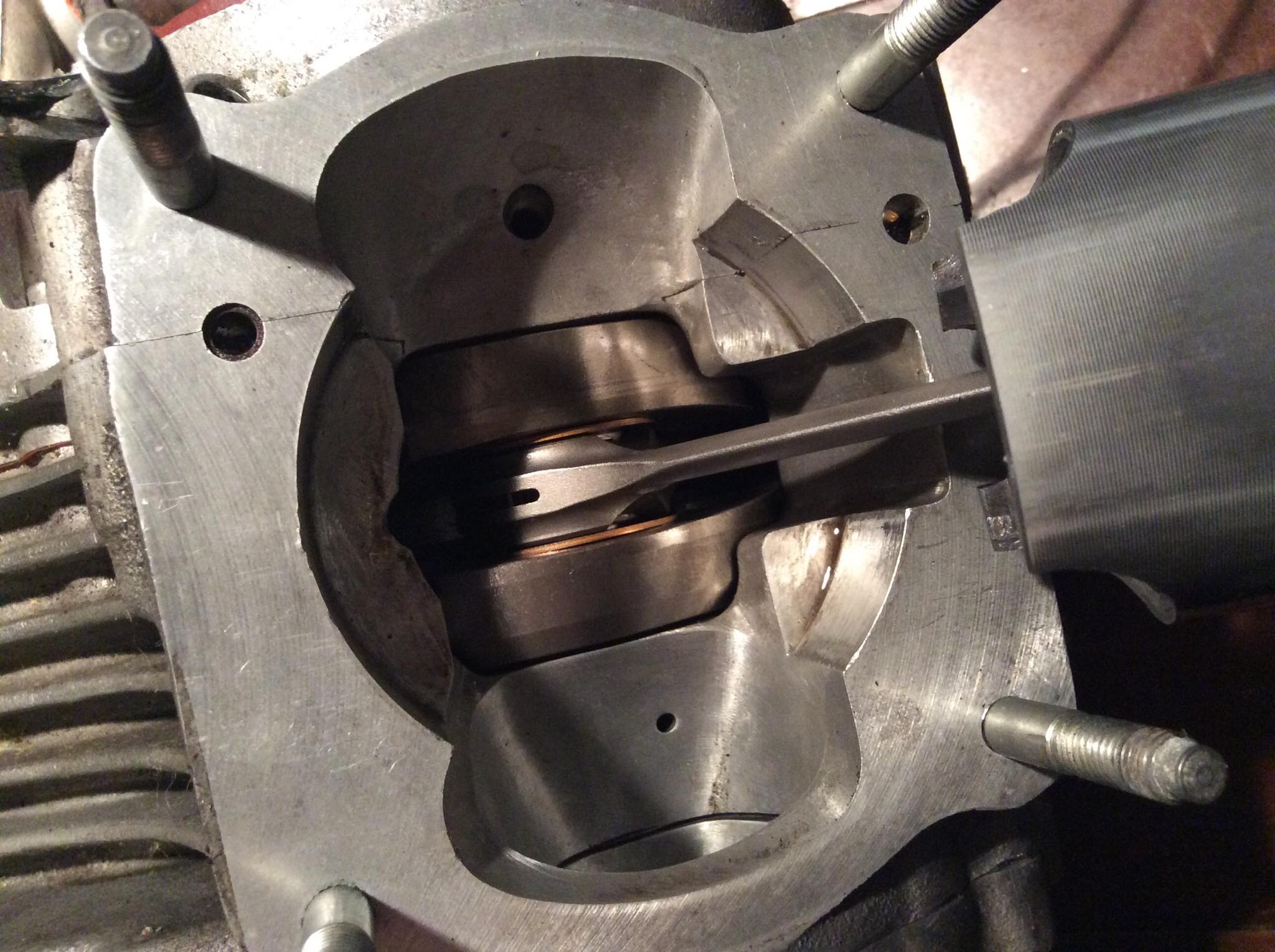

Now to remove the cylinder. These guys are impossible to crank out. They take a ground down 12mm box wrench, otherwise you’ll just round out those nuts:

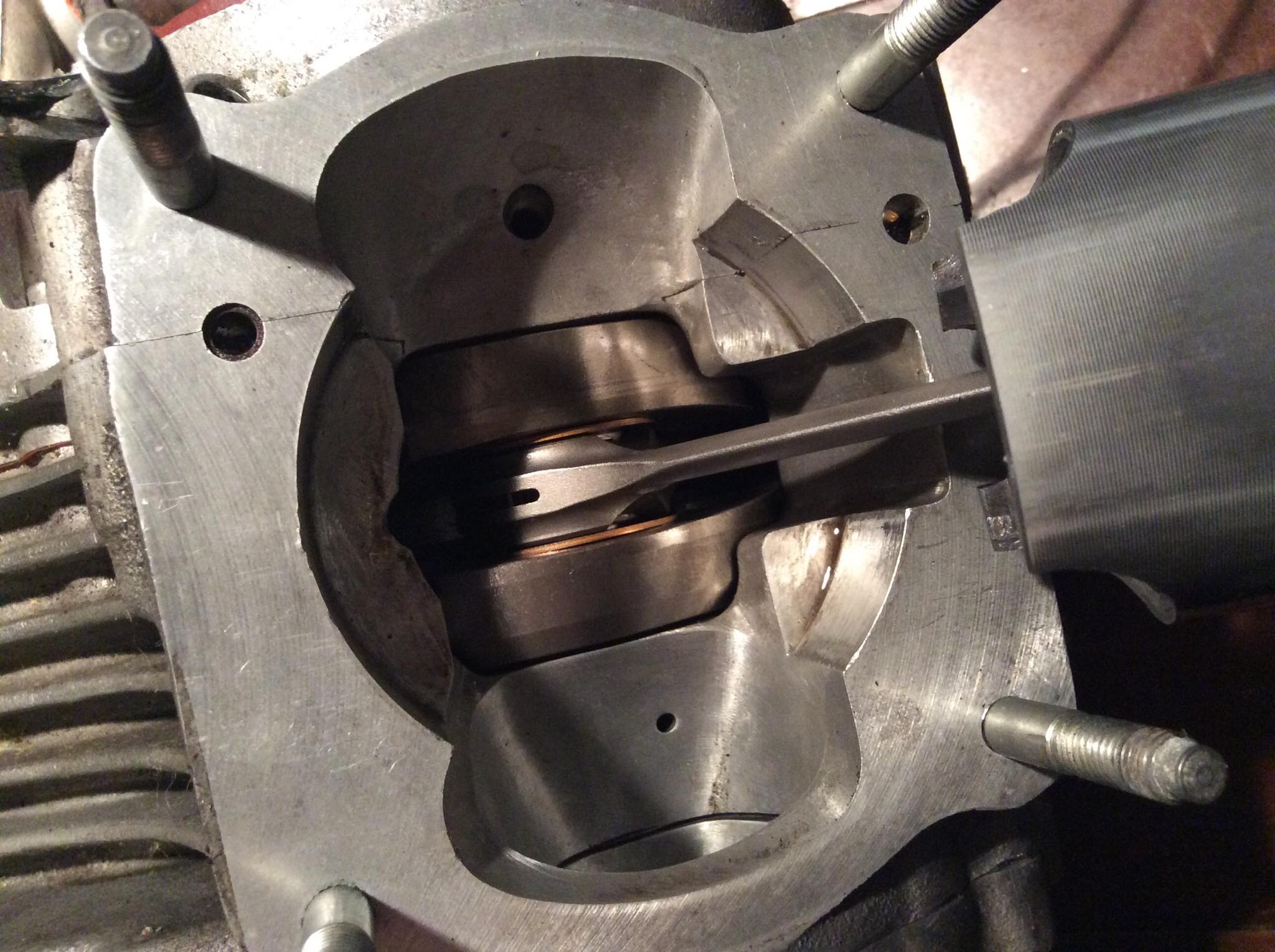

Combustion chamber top looks good:

Cylinder is in excellent condition, with really good port work. Even the base gasket looks like new.

Hash marks still visible. Piston has minimum wear and was ran pig rich, but check out that blowby:

Luckily, seller sold me the engine with a brand new piston package of the exact size I need. Someone was getting ready for a new top end?

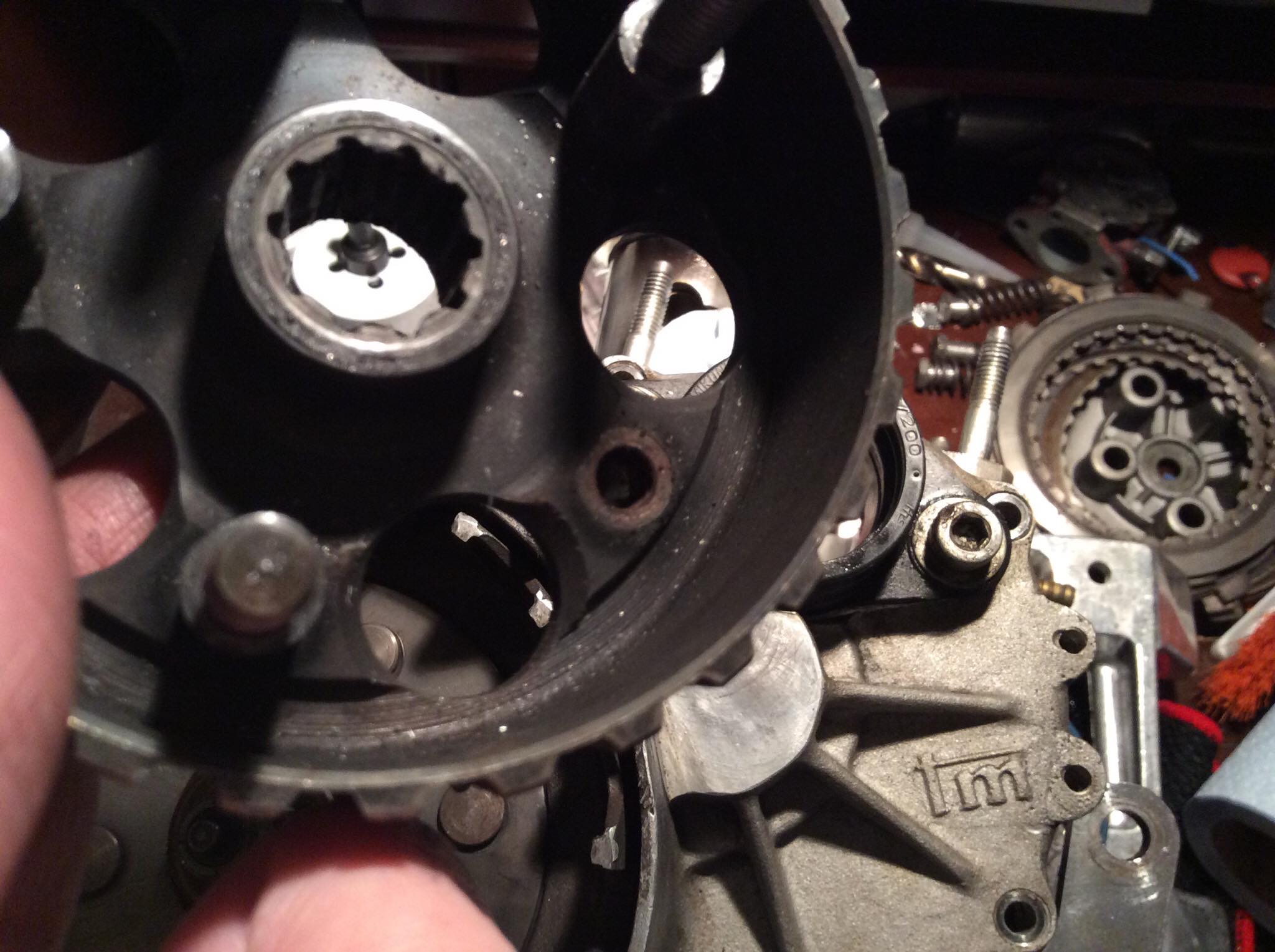

Now, with an engine that sat for 15 years, you want to inspect and change the oil seals. Rubber can dry out and degrade. On the ignition side, no problem. Bust out your motoplat holder and puller, done:

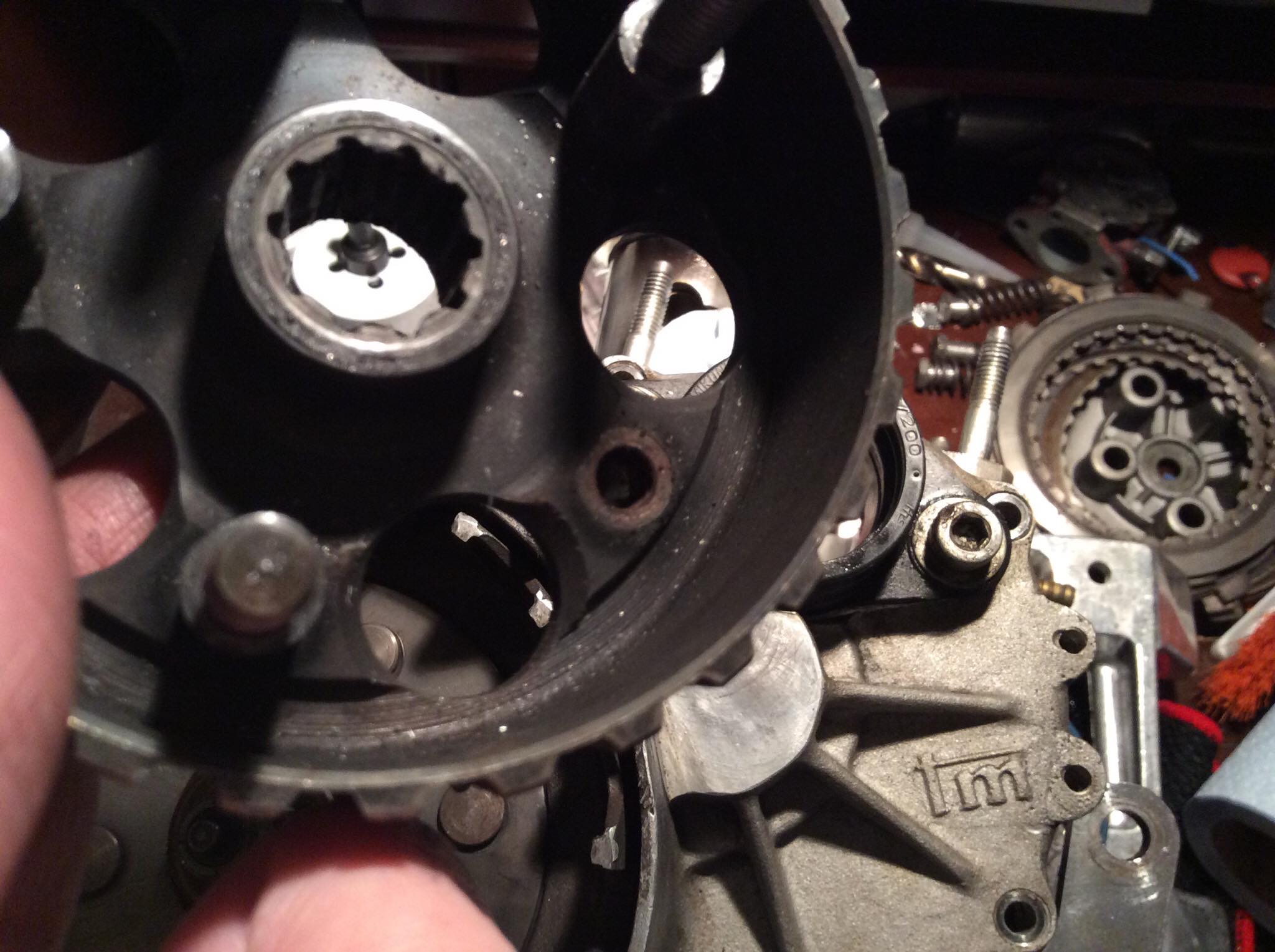

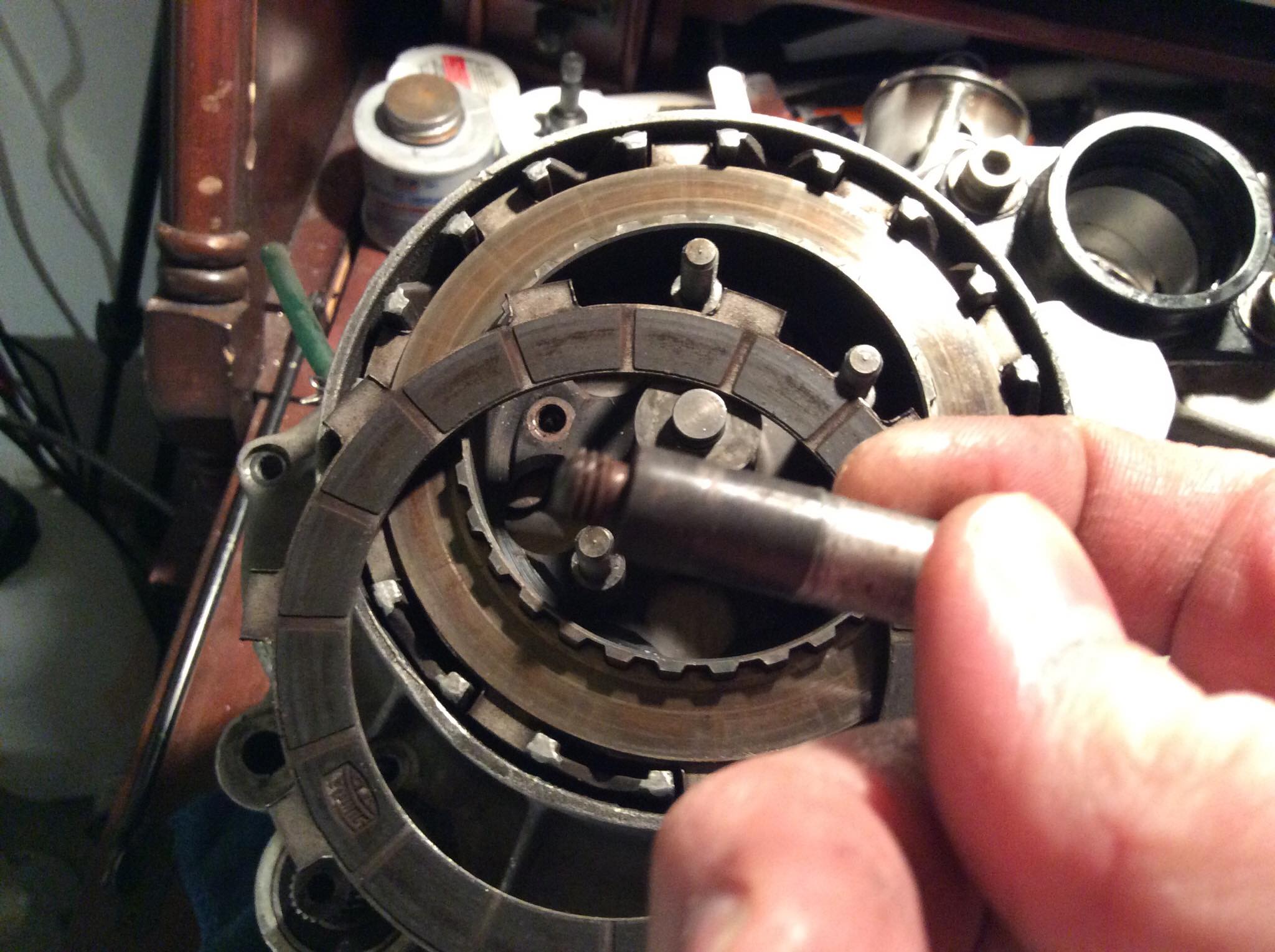

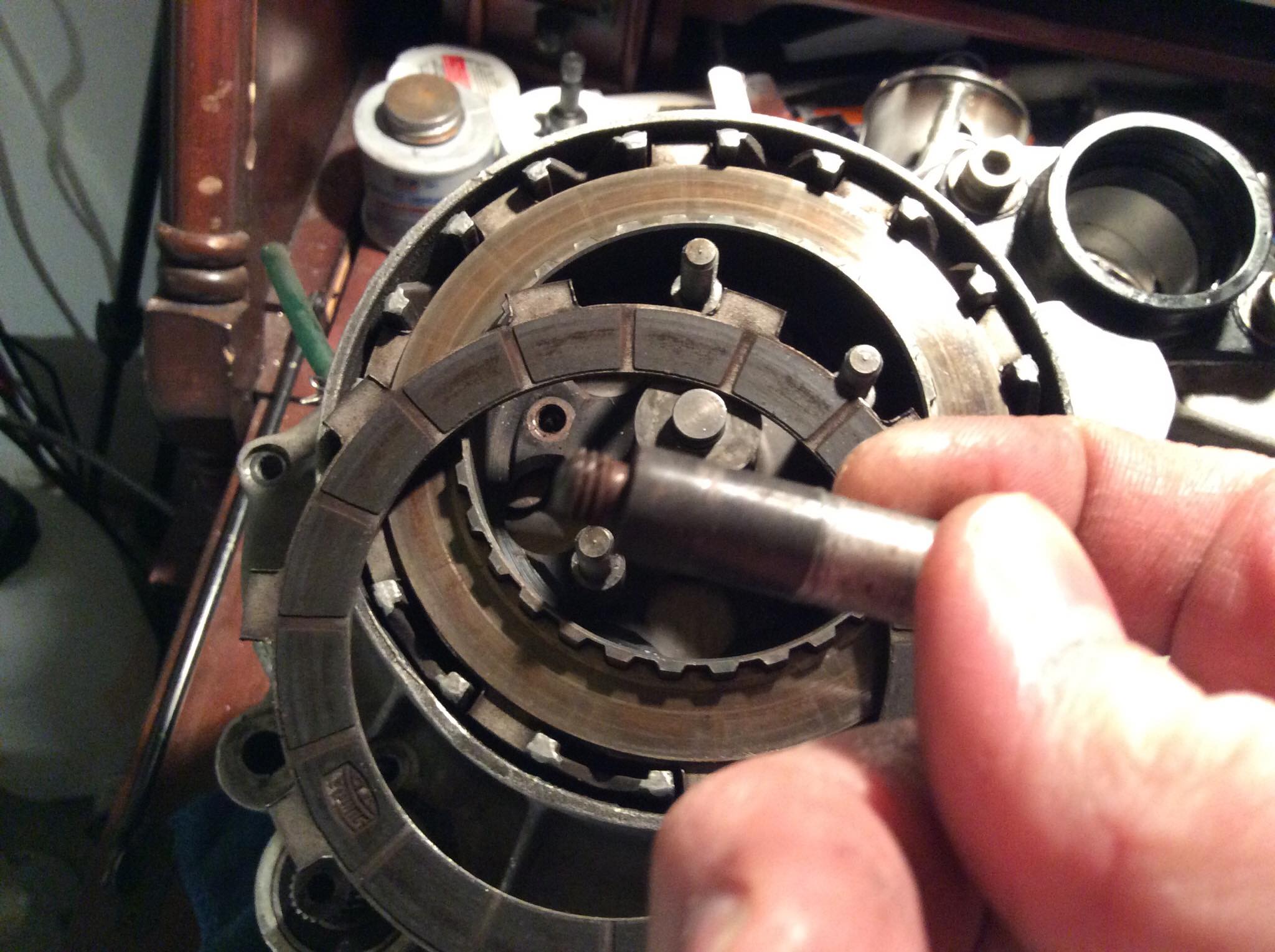

Now to tackle the other end. Pull the clutch pack, taking the opportunity to inspect the condition of the clutch itself:

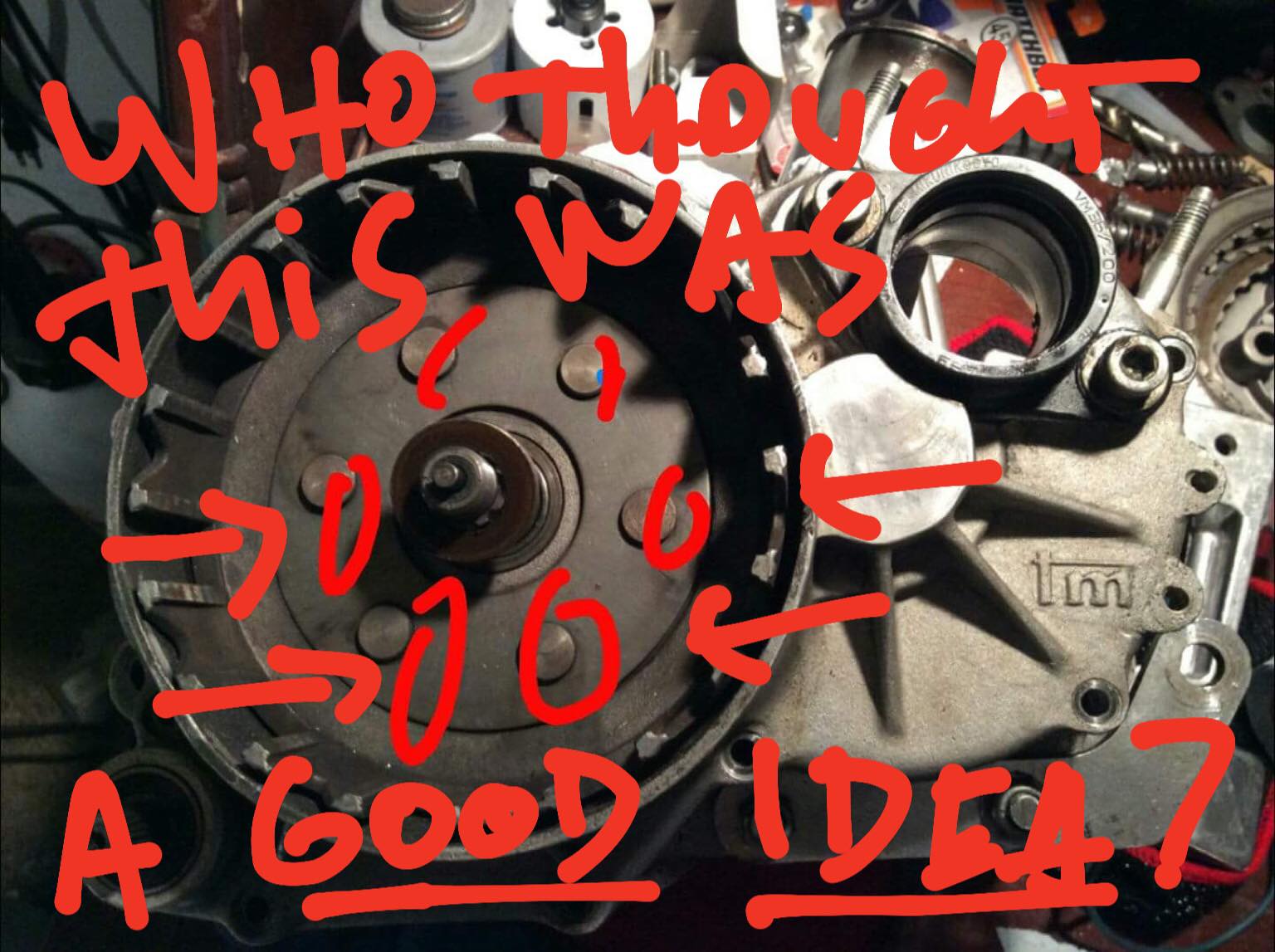

Oops moment:

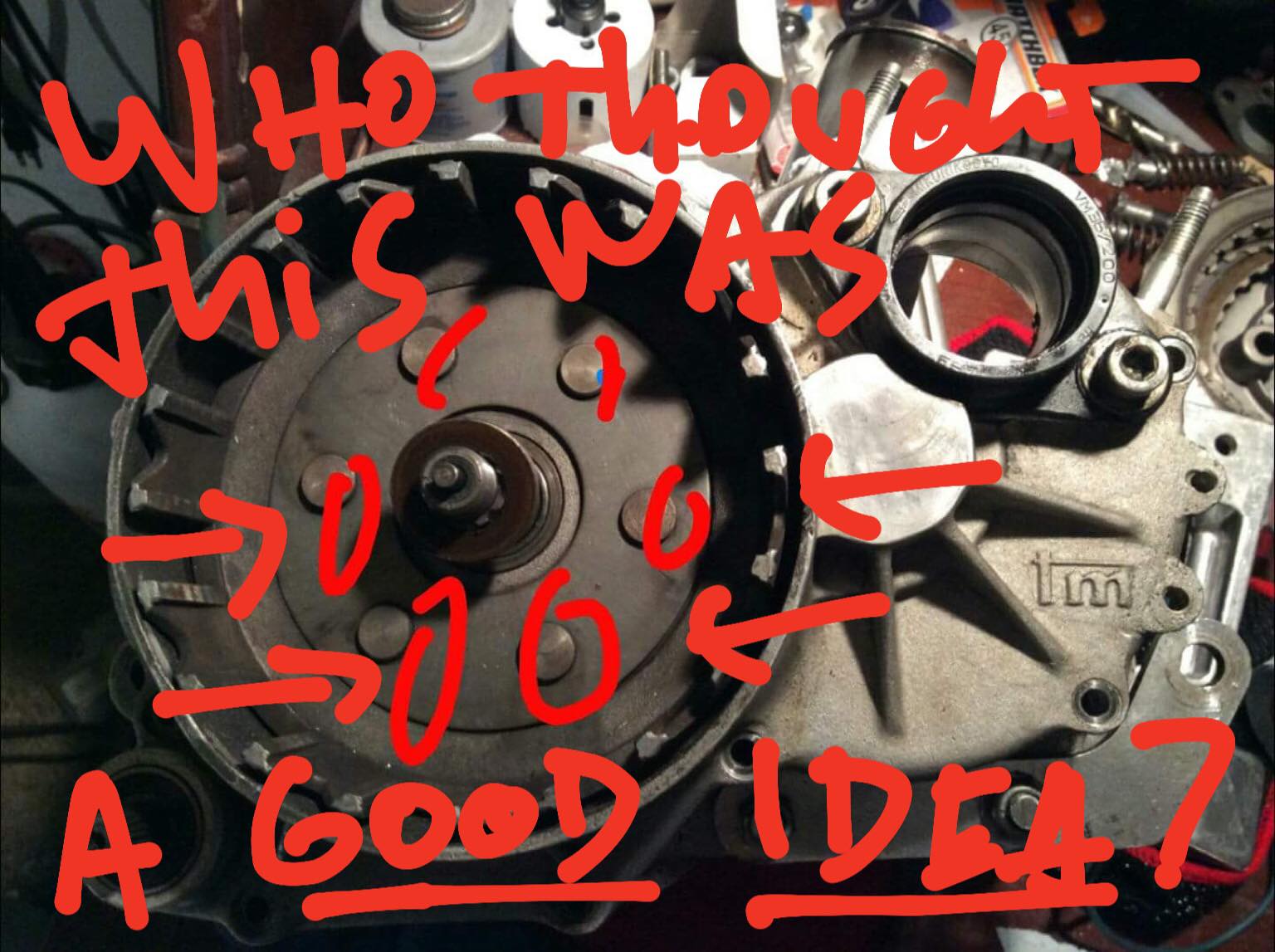

Things look good. BUT WAIT. Turns out you need to MACHINE OUT the studs that hold the clutch basket, remove the clutch basket, then open the side case to access the oil seal under the rotary valve. That is a ridiculous amount of work for a sealed engine that is holding all it’s shit right.

Considering the gearbox still had oil and the bottom end still had castor, the executive decision after a careful risk analysis was to leave that side of the engine alone. Seal was probably kept moist, and the fact that it is enclosed helps.

In any case…

New piston will go in, with a brand new wrist bearing. New oil seal on the ignition side, then I’ll close her up and move towards installation of the motor package.

Huge thanks to Mike Giessen, my shifter go-to source, for holding my hand throughout this completely alien rebuild.