Fellow KP member @MichaelPOL and I have be corresponding for the last several days. He has been struggling trying to get his newly acquired Leopard up and running. I have been trying to help him with some specific processes that he needed to go through. Some successful, others ended poorly, but not for lack of desire or enthusiasm. This guy is Determined to Succeed!! I really like that about him.

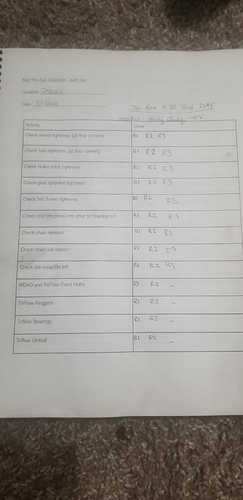

Following a more recent failure, he asked me if I could help him come up with a Checklist of things like a pilot goes through before take off. He listed a few things and I began to expand on it. Trying to categorize it into Times to Check and Frequency to Check. I know many of the items below have been learned through mistakes from ignorance. After discussing it with Micheal we decided to publish what we have come up with so far and ask that others try to contribute as seen fit.

Some items will vary by usage or situation (practice, test or race).

Prior to starting the day:

-Charge Battery. Even though the onboard ignition powers the engine (IAME) and somewhat charges the battery, the amount of energy lost during cranking is not usually recovered during a session on track. Best to start the day with a full charge on battery. You may have to charge between sessions as well

-Check Carb needle settings (return them to base line and re-tune from there if unsure they are correct)

-Check water level

-Check Brake fluid level

-Check Brake Pad wear. If more than halfway worn or using soft pads you may also check a few times throughout the day.

-Clean brake disc and pads with some brake cleaner, can just spray them down without disassembly and use emery cloth on disc to remove any oxidation

-Check brake function, firm pedal and stops well, both pads should engage rotor at same time, can do this on the stand while warming engine by giving throttle and then applying brake. Also puts a little heat into the brakes before going on course.

-Check spark plug (clean/no fouling)

-Check pump belt(s). Not a bad idea to run 2 belts. If they are solid belts, you can loop a backup over the axle and zip-tie it down. I prefer the hooked belts because they do not require pulling the axle to install.

-Check Tire wear. Wear will vary with tire choice and experience will give you a better reference of durability.

-Check “All” nuts and bolts are tight. Vibrations from engine and road surface can sometimes loosen things. Ask me how I know this.

-Check chain tension, sprocket/chain wear and alignment of sprockets. Alignment will require removal of clutch cage and a good straight edge.

-Check all safety wiring and safety pins/clips are present and secure

-Mix your fuel/oil for what you think will last you the day. Best to mix only enough for that day.

Before every session:

-Check Fuel Level

-Lube chain, prior to first run, then after each run from then on. Best done when chain is warm.

-Set tire pressures

-Check nothing hanging below the chassis rails. Brake lines, wire harnesses, etc. (They can rub on the pavement and cause damage. Ask me how I know this.  )

)

After every session:

-Lube the chain

-Check and note tire pressures (looking for signs of overheating, documenting for future reference and staggering pressures if needed)

-If testing, make a note of any issues or deficiencies and chose 1 thing at a time to change

-If you are concerned about carb settings, note where the needles ended up and check plug for any evidence of lean running or fouling. (make notes to build a reference for current conditions)

-Clean any excess oil or grime from the engine and chassis

-If you are running a data logger, you can review your data (rpm and temp reading note: sudden spikes in temp could be a sign of running too lean but are delayed in water temp readings.)

Things to do at the end of every day of running:

-Clean everything and inspect for wear/damage

-Spray down a rag with WD-40 and coat exhaust pipe and axle to prevent oxidation

Things to check periodically throughout the Season:

-Brake Pad Wear

-Bearings. Axles, hubs, spindles

-Tie-Rods

-Steering shaft bushing/bearing

-Cracks in the seat or widening of the holes in the seat at all mounting points

-Cracks in the frame or welds

-Check squareness of chassis, best done on a frame table and frequency increases with age of chassis

-Pull the Head and check for carbon deposits on top of the piston

-Pull the Exhaust Header and check for scoring on the sides of the piston/cylinder walls

-Open the exhaust pipe and check the holes in the cones are not clogged/blocked

-Clean Carburetor, replace gaskets and seals

-Bleed the brake fluid

-Always good to have spare nuts and bolts. Any locking nuts should be replaced after removal, but I usually do it after 2 or 3 removals as long as I feel good resistance when re-installing, if not replace it. (others may disagree)

-Depending on Engine Package, a Partial or Full rebuild may be required at recommended intervals (refer to your manufactures recommendations)

I am sure I am leaving some things out, but cannot not think of it at this time. I will add more when it comes to me. I seem to recall a Thread on here that covered much of this, but could not find it or one with as much detail as this.

I feel like many of us take this information for granted and there are a lot of people new to karting that may not have this knowledge or know where to find it. If this can prevent someone from making a costly mistake, then it serves a purpose.

Please feel free to comment and/or add to this list.